Automobile load controller

A technology of rated load and joint sleeve, applied in the field of auto parts, can solve the problems of low safety, affecting public transportation, property damage, etc., to reduce safety hazards and improve safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

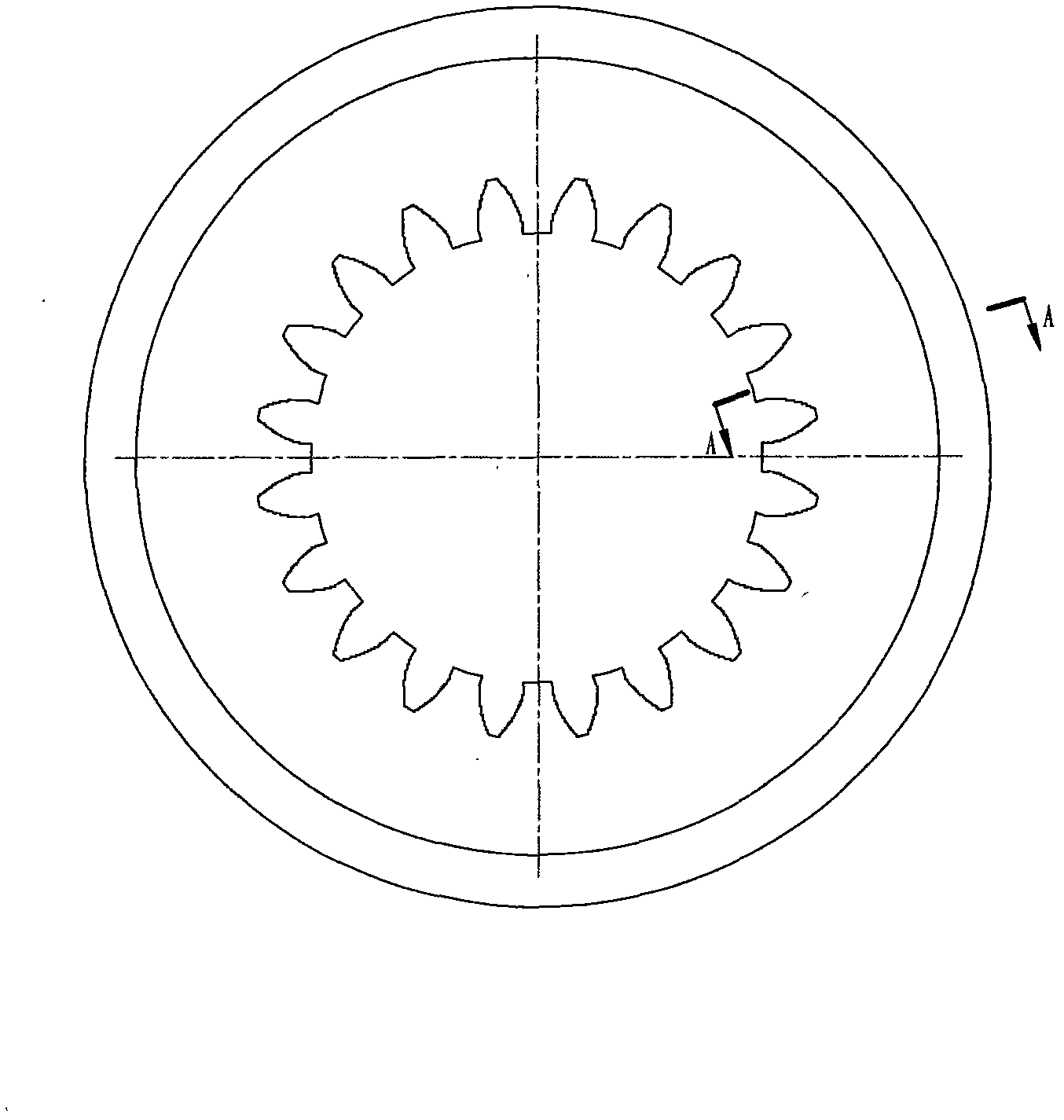

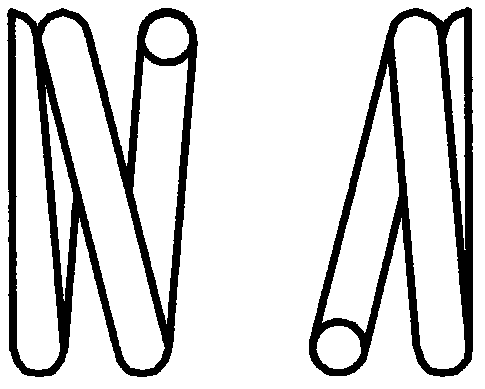

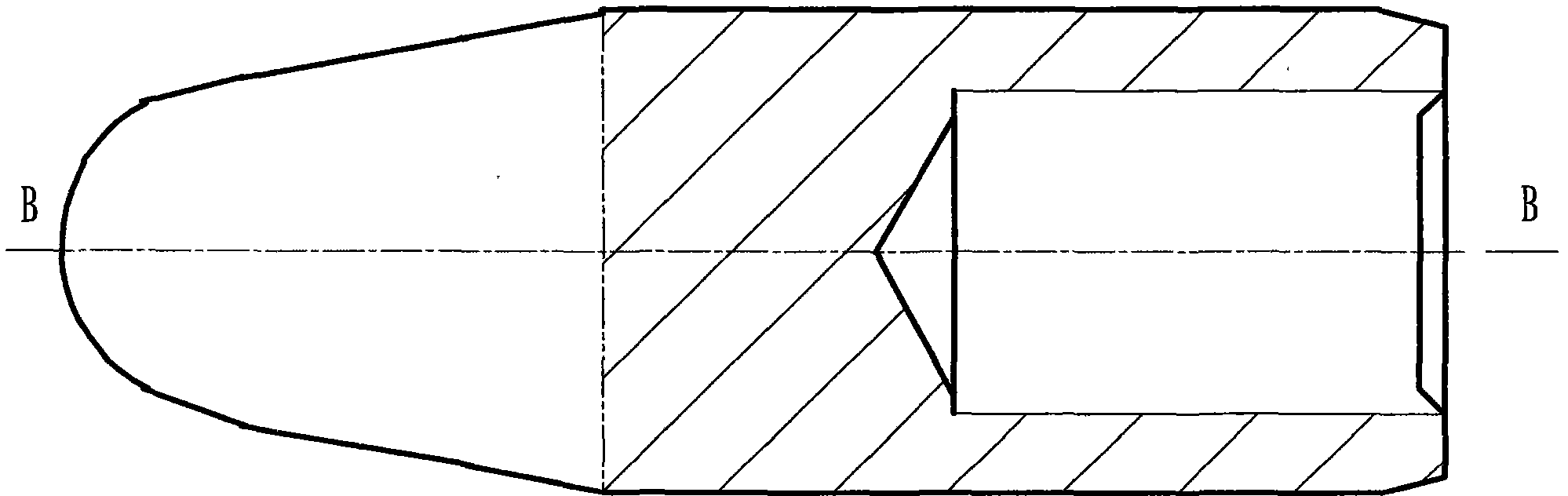

[0019] Patent of the present invention: divided into two parts, input and output, the input part is directly connected with the one-axis spline by processing the internal spline of the joint sleeve, and the output torque of the engine is transmitted to the joint sleeve (1) through the spline, and the joint sleeve is transmitted to the output Part, when the torque required by the transmission is less than or equal to the torque required by the design load, the first shaft is normally meshed with the vehicle load controller and the transmission operates normally. When the torque required by the transmission is greater than the torque required by the design load, due to the meshing 2) The stressed compression spring (4) retracts under the axial pressure, the first shaft is separated from the car load controller, the transmission stops rotating and makes a rattling sound, the car stops moving forward, and the load control function is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com