Construction method for anchoring, separating and positioning submarine hammer body of anchor body

A technology of hammer body and anchor body, which is applied to anchor points, ship parts, transportation and packaging, etc., can solve the problems of large investment, and achieve the effect of simple operation and great promotion and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

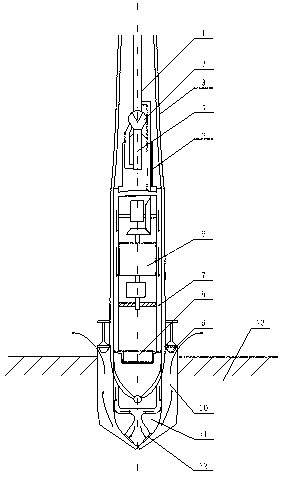

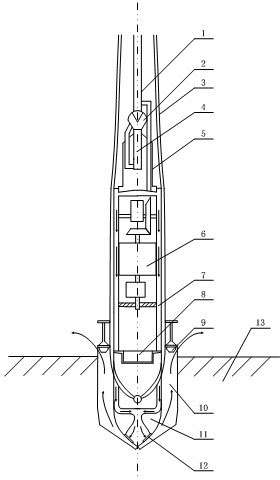

[0013] Turn on the winch and enter the neutral gear, so that the hammer body 8 and the anchor body 11 on the winch enter the exile state and quickly enter the sea;

[0014] (2) Immediately open the upper electromagnetic valve on the hammer body 8 upper end, utilize the high-pressure gas of the hammer body 8 itself to carry out the high-pressure power-assisted sprinkler head 2 jetting, by means of the reaction force of jetting, make the hammer body 8 and the anchor body 11 insert in the seabed 13 rapidly;

[0015] (3) After the anchor body 11 is inserted into the seabed 13, open the vibrating mechanism 6 of the hammer body 8 and the high-pressure nozzle 12 of the anchor body 11. The vibrating mechanism 6 includes an axial vibration mechanism and a lateral vibration mechanism, and has a downward impact force. And the vibration reaming force to the surroundings, when the force acts on the hammer body 8, it is transmitted to the anchor body 11, so that the hammer body 8 and the anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com