Equipment for sticking paint prevention paster to chopsticks and dedicated paster belt

A technology of chopsticks and stickers, applied in the field of equipment for rolling and pasting anti-paint stickers on chopsticks, can solve the problems of low efficiency of manual work, achieve the effect of promoting practical significance, realizing mechanization and automation, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The device of the present invention will be further described below with reference to the accompanying drawings and in conjunction with a specific embodiment.

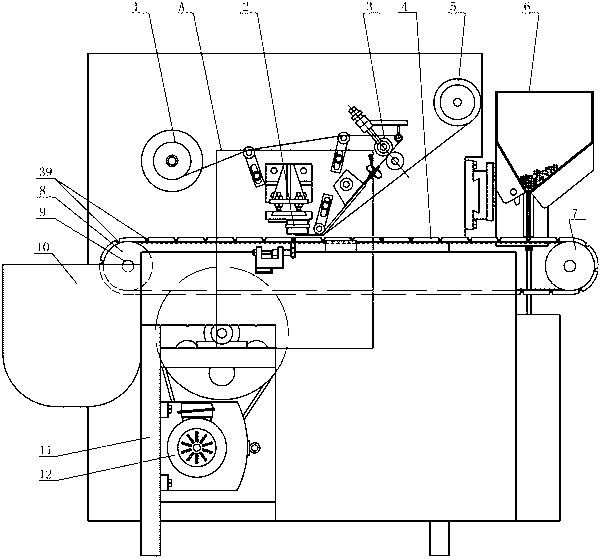

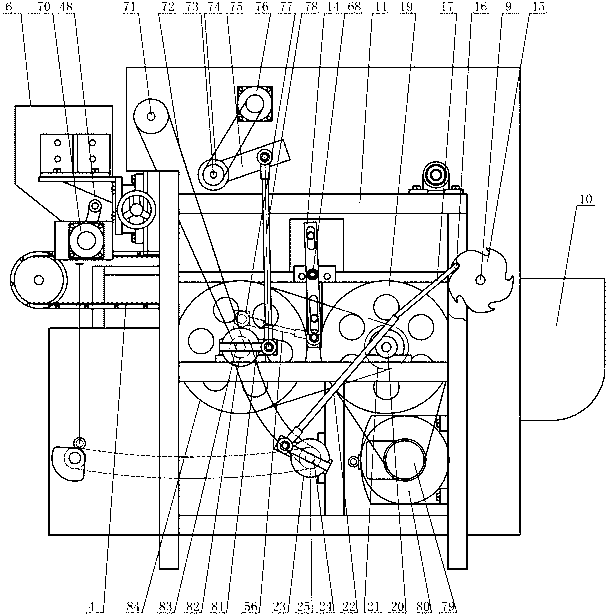

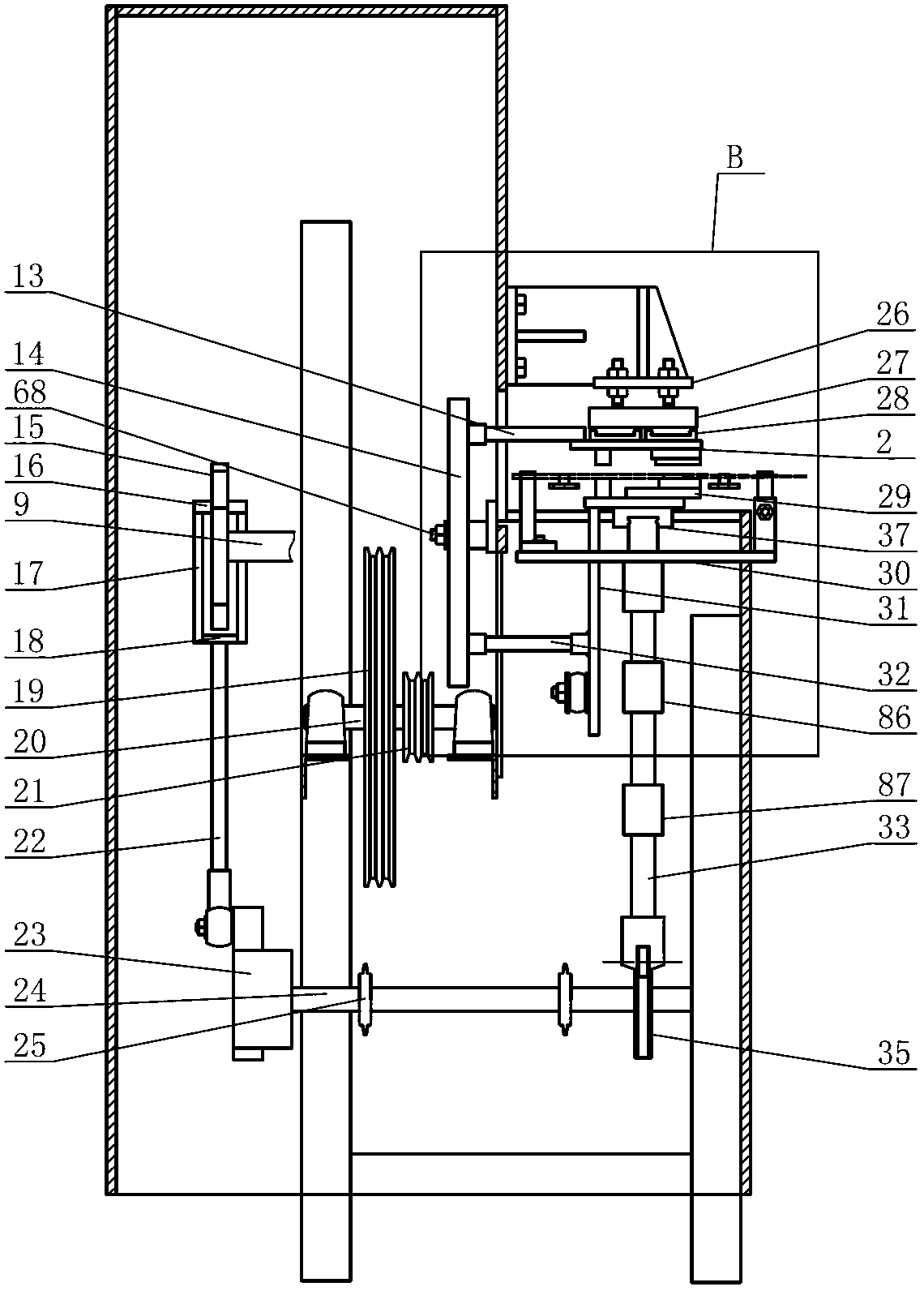

[0029] refer to figure 1 , the figure shows the overall structure of an example of the device of the present invention, in this example, the main part of the device is a box structure. The power system is arranged in the box body. A material receiving box 10 is established at the middle and lower part of the left side in front of the casing, and a chopsticks bucket 6 is established at the middle and upper part of the right side. The conveyer belt 4 that is used to convey chopsticks spans across the front middle part of the casing, and the sticker conveying mechanism is located above the conveyer belt. The rolling mechanism corresponds to the left position in the middle part of the conveyor belt 4 .

[0030] refer to Figure 1-5 , in this example, the chopsticks transmission mechanism includes two closed conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com