Hydrolysis acidizing settling pond and application thereof

A hydrolysis, acidification and sedimentation tank technology, applied in the field of wastewater treatment, can solve problems such as poor phosphorus removal effect, easy blockage, and stagnant water in the factory area, and achieve the effect of improving the effect and preventing blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

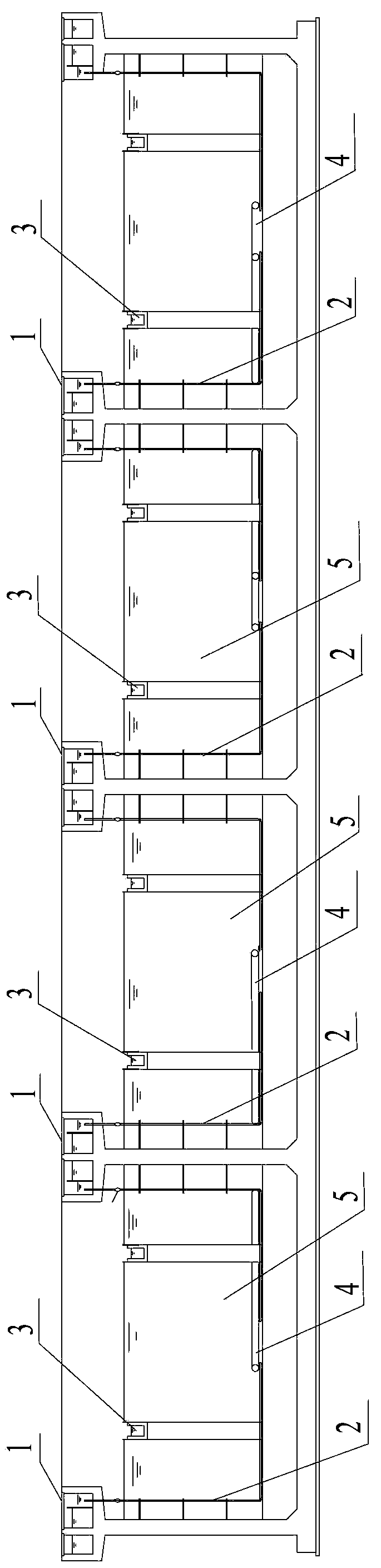

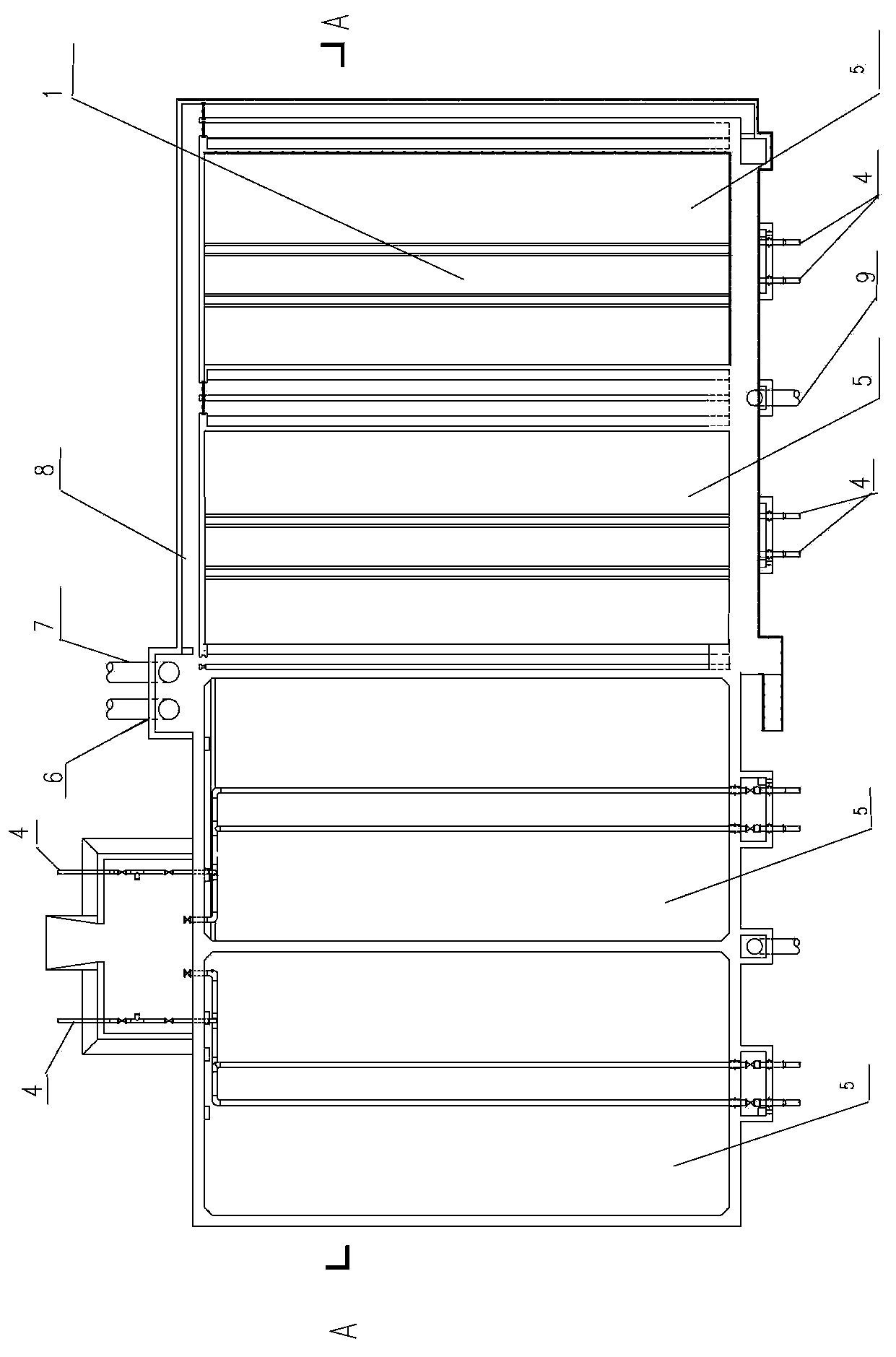

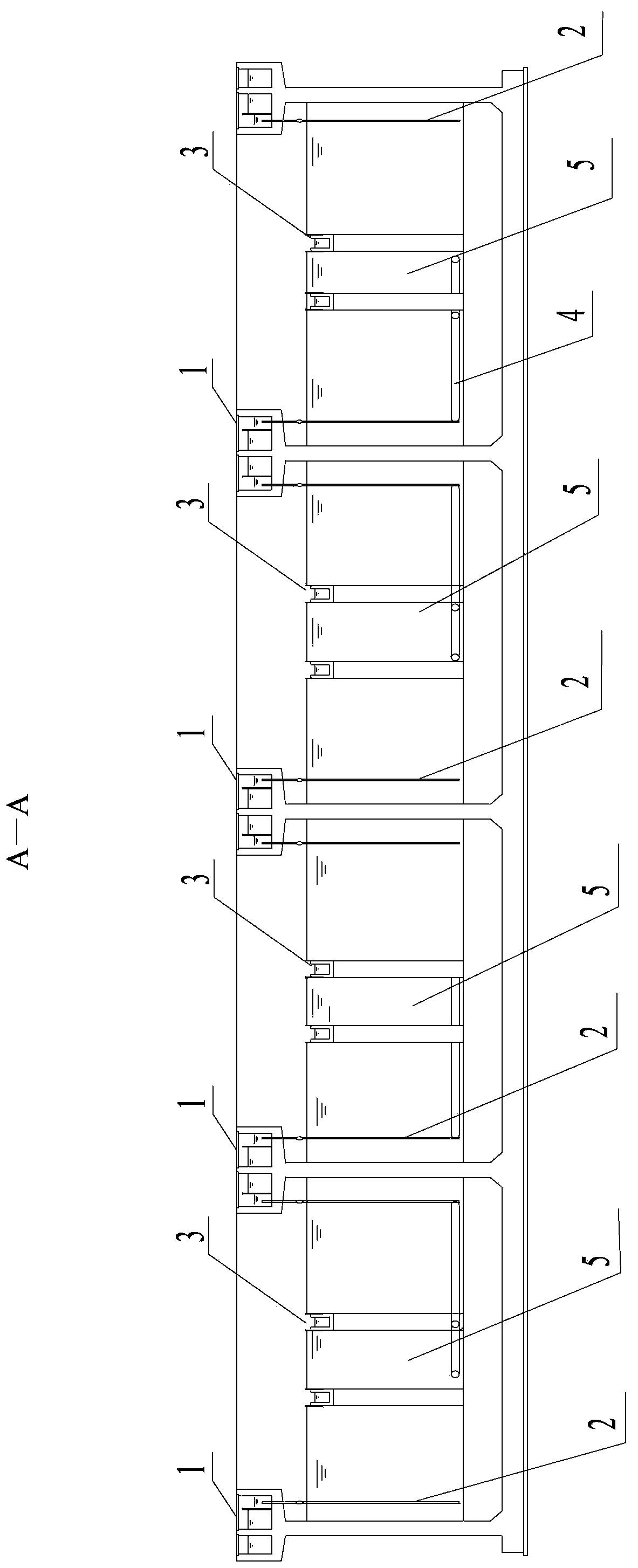

[0027] Example 1: Hydrolysis acidification sedimentation tank

[0028] See figure 2 with image 3 . The hydrolysis acidification sedimentation tank has 4 treatment tank compartments 5, each treatment tank compartment 5 has a water distribution pipe 2, the nominal diameter of the water distribution pipe is DN80, and the water distribution pipe 2 is connected with the water distribution channel 1 and vertically leads to the bottom of the treatment tank compartment; The hydrolysis acidification sedimentation tank is connected to the grit tank through a pipeline and the inlet channel 8. The hydrolysis acidification sedimentation tank is provided with a mud pipe 4 and a mud pump, and the hydrolysis acidification sedimentation tank is connected to the aerobic tank through a mud pipe 4 and a mud pump. . A sludge return pipe 6 is provided in the treatment tank grid, and the sludge return pipe 6 is connected to the aerobic tank.

[0029] The treatment pool grid 5 is divided into upper a...

Embodiment 2

[0030] Example 2: Treatment of wastewater

[0031] In the embodiment, the method for measuring the dissolved oxygen and orp value is to use the online automatic monitoring instrument to measure, the dissolved oxygen is measured using the HJ / T99-2003 (photoelectric method) standard, and the orp measuring instrument is produced by Beijing Tianjian Innovation Instrument Co., Ltd., model: TORP10AC.

[0032] The hydrolytic acidification sedimentation tank system of Example 1 was used. The waste water generated in the grit tank enters the hydrolytic acidification sedimentation tank through the waste water pipe, the inlet channel 8 and the water distribution channel 1, and is transported to the bottom of the treatment tank through the water distribution pipe 2 to control the dissolved oxygen 0.2mg / L and the orp value of the tank -200mv, so that the hydrolysis and acidification process can take place. After 5 hours of hydrolysis and acidification in the tank, the sewage flows out from the...

Embodiment 3

[0034] Example 3: Treatment of wastewater

[0035] The waste water generated in the grit tank enters the hydrolytic acidification sedimentation tank through the waste water pipe, the water inlet 8 and the water distribution channel 1, and is transported to the bottom of the tank through the water distribution pipe 2. The dissolved oxygen of the tank is controlled to be 0.5mg / L and the orp value is -100mv, so that The process of hydrolysis and acidification can take place. After 2 hours of hydrolysis and acidification in the pond, the sewage flows out from the upper outlet channel 3 of the hydrolysis acidification sedimentation tank, and enters the next aerobic tank through the pipeline. The sludge return pipe 6 is connected to the aerobic tank, and the aerobic tank intermittently returns the sludge to the hydrolytic acidification sedimentation tank, and the return flow is 3 hours a day, and the return ratio is 0.2:1.

[0036] The phosphorus removal effect of the hydrolysis acidific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com