Agomelatine sulfuric acid composition and preparation method thereof

A technology of agomelatine and compound, applied in the field of agomelatine sulfuric acid compound and preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

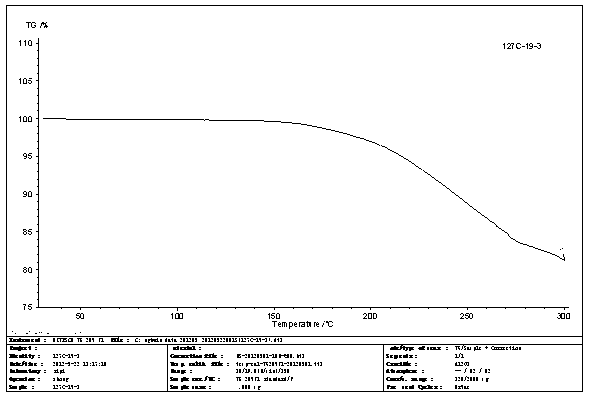

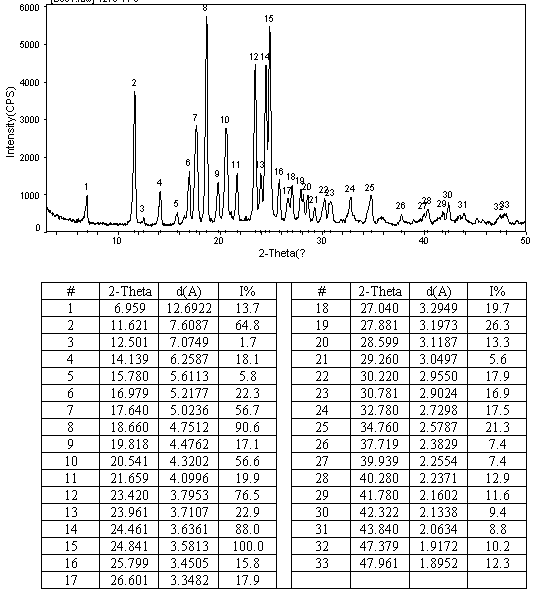

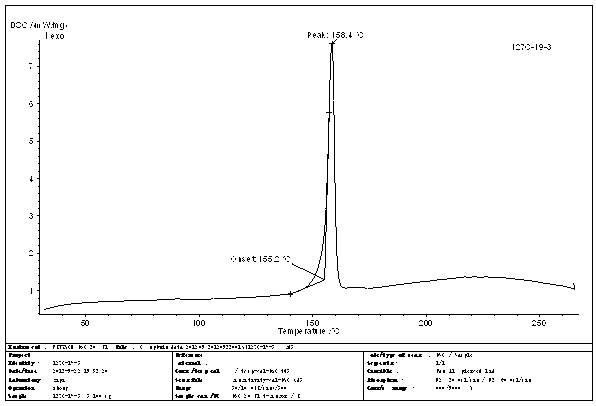

[0034] Stir and dissolve 10.0g agomelatine in 50mL dichloromethane, add 4.1g concentrated sulfuric acid at 10°C, slowly precipitate crystals under stirring, continue to stir and lower the temperature to 0°C to complete the crystallization; Washed twice with 10 mL of methane, dried at 80°C to obtain 13.4 g of white solid; purity 99.5%, yield: 95.5%. mp: 154.0~158.0°C. KF: 0.465%.

Embodiment 2

[0036] Stir and dissolve 10.0g of agomelatine in 50mL of acetone, add 4.2g of concentrated sulfuric acid (or a pre-configured concentrated sulfuric acid in acetone solution) at 10°C, stir overnight at room temperature to complete the crystallization; filter, and wash the solid with 10mL of acetone Twice, dried at 80°C to obtain 13.6 g of white solid; purity: 99.6%, yield: 96.9%. mp: 154.5~158.0°C. 1 H-NMR (400MHz, d 6 -DMSO): δ 10.88 (s, 2H), 8.21 (s, 1H), 7.82 (d, 1H), 7.70 (d, 1H), 7.61 (s, 1H), 7.32~7.24 (m, 2H), 7.16 (d, 1H), 3.94 (s, 3H), 3.34 (b, 2H), 3.12 (t, 2H), 1.85 (s, 3H). 1 H-NMR (400MHz, d 6 -DMSO+D 2 O): δ 7.80 (d, 1H), 7.69 (d, 1H), 7.56 (s, 1H), 7.32~7.23 (m, 2H), 7.15 (dd, 1H), 3.92 (s, 3H), 3.34 ( t, 2H), 3.12 (t, 2H), 1.84 (s, 3H). KF: 0.620%. S element analysis results: (C 15 h 17 NO 2 ?H2 SO 4 ) Calculated value S% (9.39%), measured value S% (9.23%).

Embodiment 3

[0038] Stir and dissolve 10.0g agomelatine in 20mL of methanol, cool down to 0°C, add 4.1g of sulfuric acid, stir to dissolve, add 40mL of acetone, continue stirring overnight to complete the crystallization; filter, wash the solid twice with 10mL of acetone, 80 Dry at °C to obtain 12.8 g of white solid; purity: 99.8%, yield: 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com