Shockproof tenon engaged flatly-built connecting brick

A technology of mortise and flat laying, applied in the direction of building components, walls, buildings, etc., can solve the problems of weak impact resistance, easy loosening and stripping, brick wall collapse, etc., achieve strong impact resistance, improve earthquake resistance, The effect of improving the bite strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

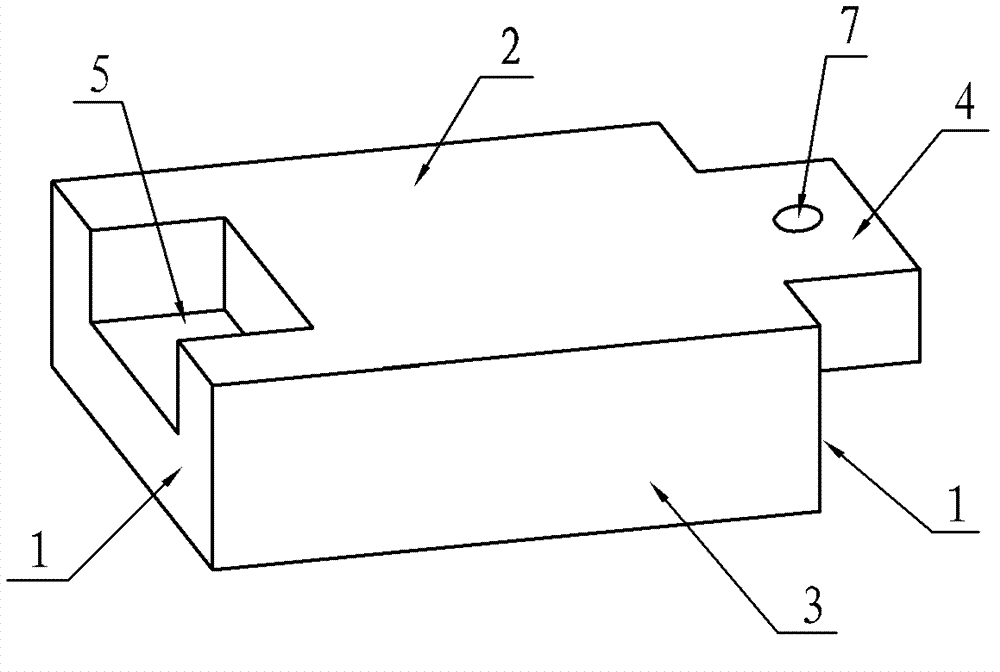

[0026] Embodiment 1: A kind of anti-shock mortise joint flat laying connection brick, such as figure 1 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, it includes a docking surface 1, a stacked end surface 2 and a side surface 3. On the right docking surface 1, a protruding tenon 4 is provided, and on the left docking surface 1, a tenon recess 5 is provided, and the protruding tenon The cross-sectional shape of 4 is rectangular, and the upper end surface of the protruding tenon 4 is flush with the upper stacked end face 2 of the brick. The width of the block is 2 / 3, and the protruding tenon 4 is located in the middle of the butt joint surface of the brick. The protruding length of the protruding tenon 4 is 35 mm; On 2, it is a double-opening pit, and the shape and size of the tenon pit 5 correspond to the protruding tenon 4, that is, when the protruding tenon 4 of one brick is inserted into the tenon pit 5 of another brick, two bricks The four sides of the rele...

Embodiment 2

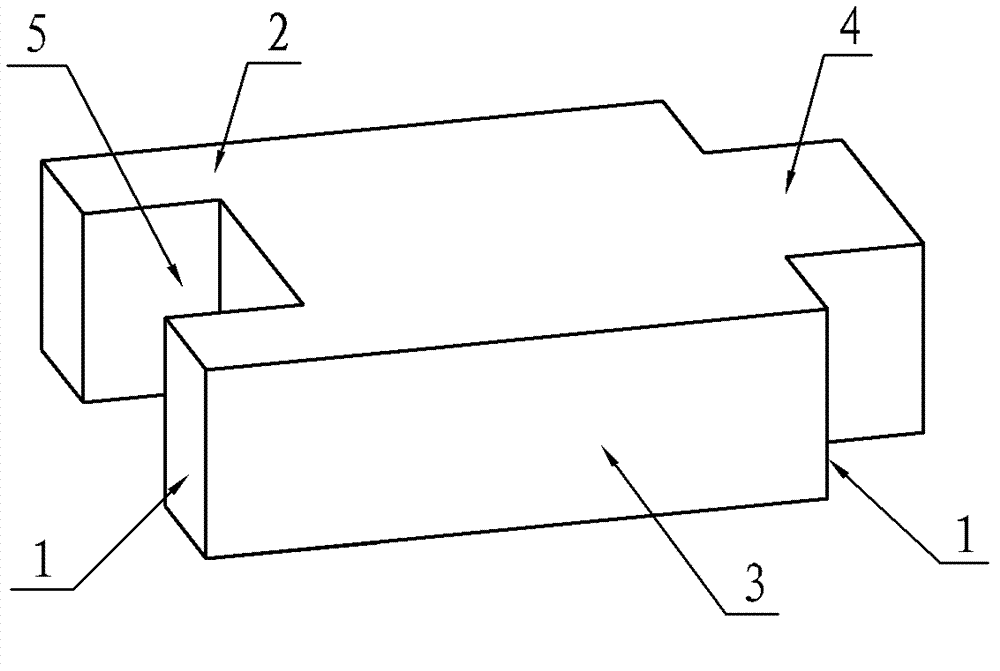

[0027] Embodiment 2: as figure 2 As shown, it is similar in structure to Embodiment 1, except that the thickness of the protruding tenon 4 and the depth of the tenon pit 5, in this example, the thickness of the protruding tenon 4 is the same as the thickness of the brick; 5 is three opening type gaps at the bottom.

Embodiment 3

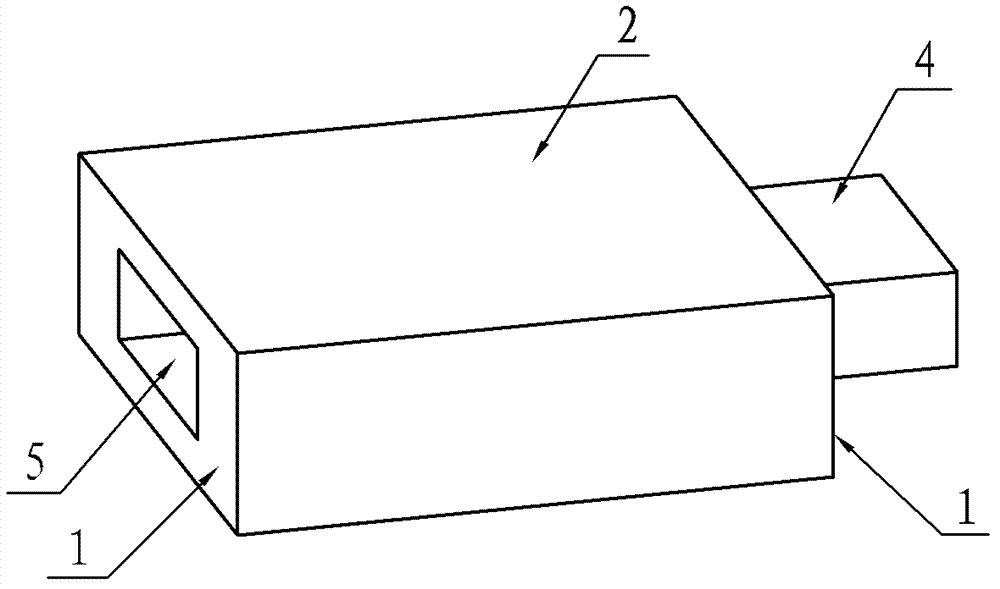

[0028] Embodiment 3: as image 3 As shown, it is similar in structure to Embodiment 1, except that the protruding tenon 4 and the tenon recess 5 are set differently. In the central part, the mortise and tenon pit 5 is a single opening cave.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Protrusion length | aaaaa | aaaaa |

| Protrusion length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com