Caving control method for fully mechanized mining face tip mining road way top plate

A fully mechanized mining face and mining roadway technology, applied in ground mining, earth drilling, underground mining, etc., can solve the problems of polluting the working face environment, shortening the roof pressure and caving step distance, and lack of scientific and reasonable calculation methods , to achieve the effect of improving safety production conditions and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] specific implementation plan

[0040] To implement a method for controlling the caving of the roadway roof at the end of the fully mechanized mining face of the present invention, the main steps are as follows:

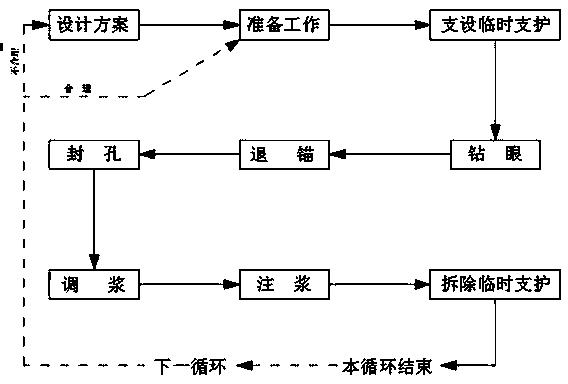

[0041] Design the crushing plan→preparation work (including processing the eaves of the roof, debugging the air duct, grouting pump, etc.)→setting up temporary support→drilling→sealing→removing the anchor→grouting→grouting→remove Temporary support → next cycle.

[0042] For the specific implementation plan, see the flow chart figure 1 . The specific implementation process is as follows:

[0043] (1) Design the crushing scheme

[0044] is the distance between holes in the same direction, in m, is the aperture, in m, Adjustment factor for drilling density, medium stable roof Take 1.25 to stabilize the top plate Take 1, very stable top plate Take 0.8, when designing the drilling, and The relationship is: .

[0045] In the area of the roof th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com