Concrete sprayer

A technology of concrete spraying machine and spraying device, which is applied in the field of underground roadway reinforcement and concrete spraying machine, can solve the problems of underground roadway pollution, uneven batching, flying dust, etc., and achieve the effects of reducing labor intensity, eliminating replacement and reducing dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

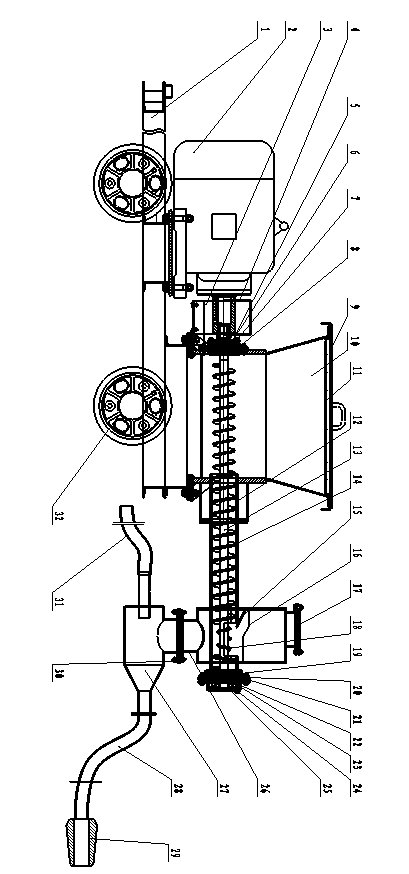

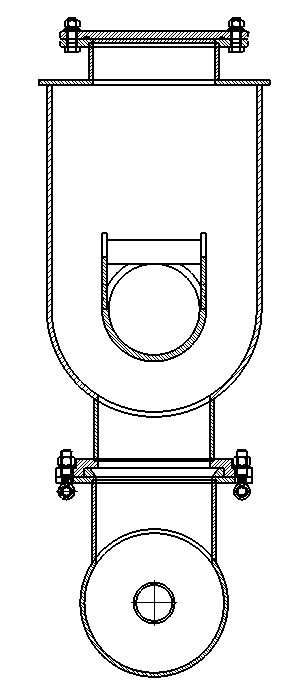

[0033] Embodiment one: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, this embodiment is composed of a supporting device, a spiral stirring device, a powder density changing chamber and a spraying device. The spiral stirring device is arranged on the support device, the spiral stirring device passes through the powder density changing chamber and is connected with the powder density changing chamber, the injection device is arranged under the powder density changing chamber and is connected with the powder density changing chamber, the powder The density changing bin is a closed cavity with high-pressure gas at one end. The top of the powder density changing bin is provided with an upper cover 17, the lower part of the powder density changing bin is provided with a feeding port, and the middle part of the powder density changing bin is provided with a stopper. feeding device.

[0034] The supporting device is composed of a steel beam 1 and two sets of w...

Embodiment 2

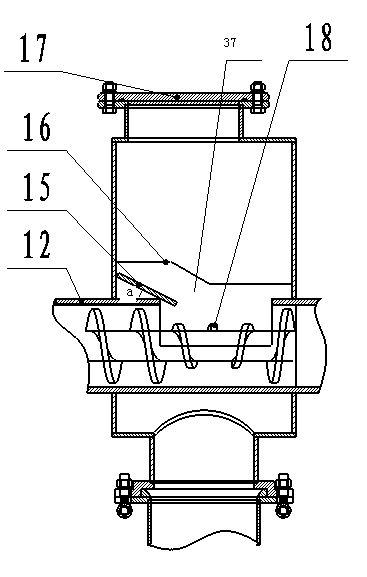

[0042] Embodiment two: Figure 8 , Figure 9 As shown, the shape of the powder density changing bin in this embodiment is rectangular, the top of the powder density changing bin is provided with an upper cover 17, and the bottom of the powder density changing bin is provided with a material outlet—feeding port, feeding tube 12 Pass through the powder density change bin, and the feeding tube 12 located in the inner cavity of the powder density change bin is provided with a discharge port 37, the discharge port 37 is a square port, and the left side of the discharge port 37 is provided with a stopper. The feeding device, the blocking device is composed of 4 plates, wherein two vertical plates 38, 39 are arranged parallel to the axis of the feeding tube and welded with the feeding tube, and the third vertical plate 40 is arranged perpendicular to the axis of the feeding tube and connected with the feeding tube axis. The feeding tube is welded, the bottom edge of the third vertical...

Embodiment 3

[0043] Embodiment 3: The feeding opening of the powder density changing bin of this embodiment is a square, and other structures are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com