Valve stroke variable adjusting system

A valve lift and adjustment system technology, applied in non-mechanically actuated valves, engine components, machines/engines, etc., can solve the problems of inability to control valve opening, difficult installation and control, complex structure, etc., to reduce impact and vibration, improve fuel efficiency, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

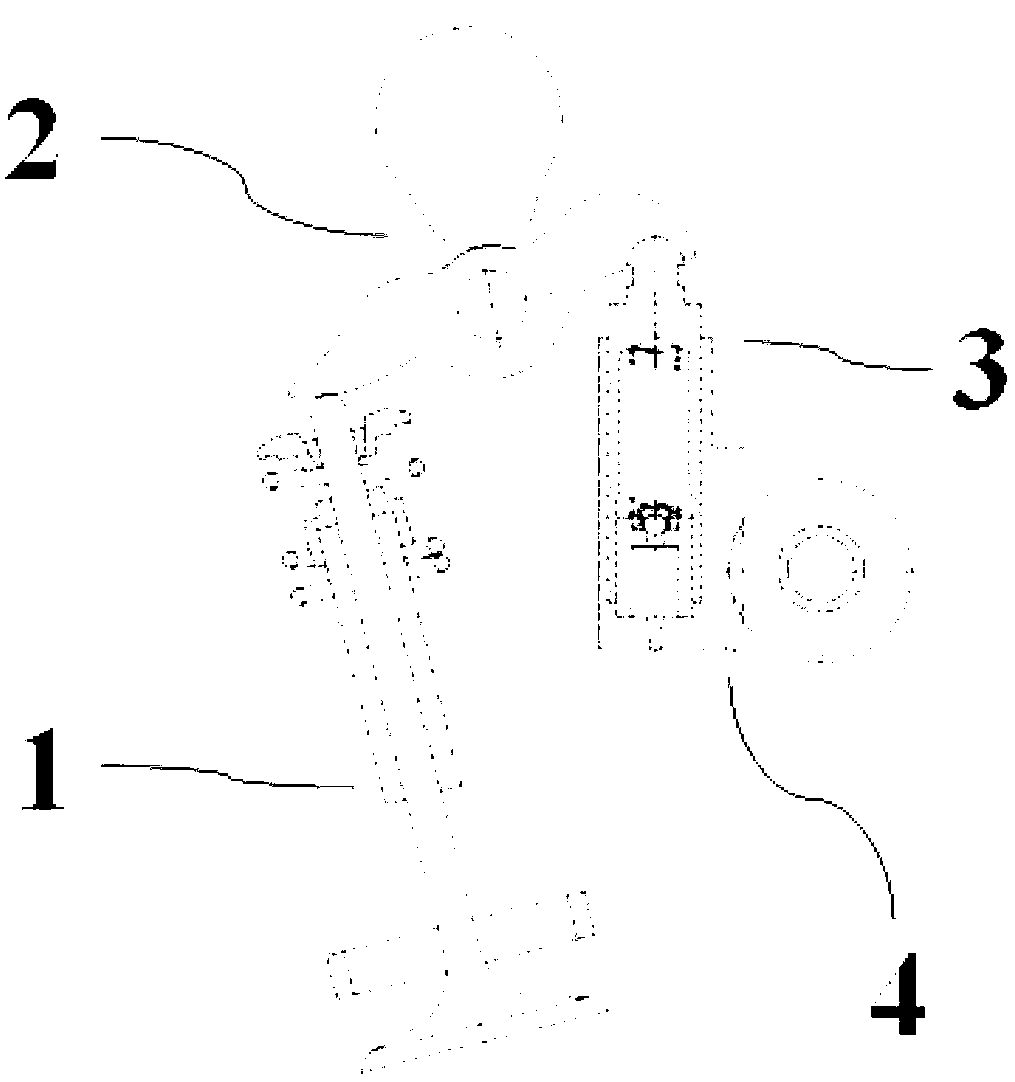

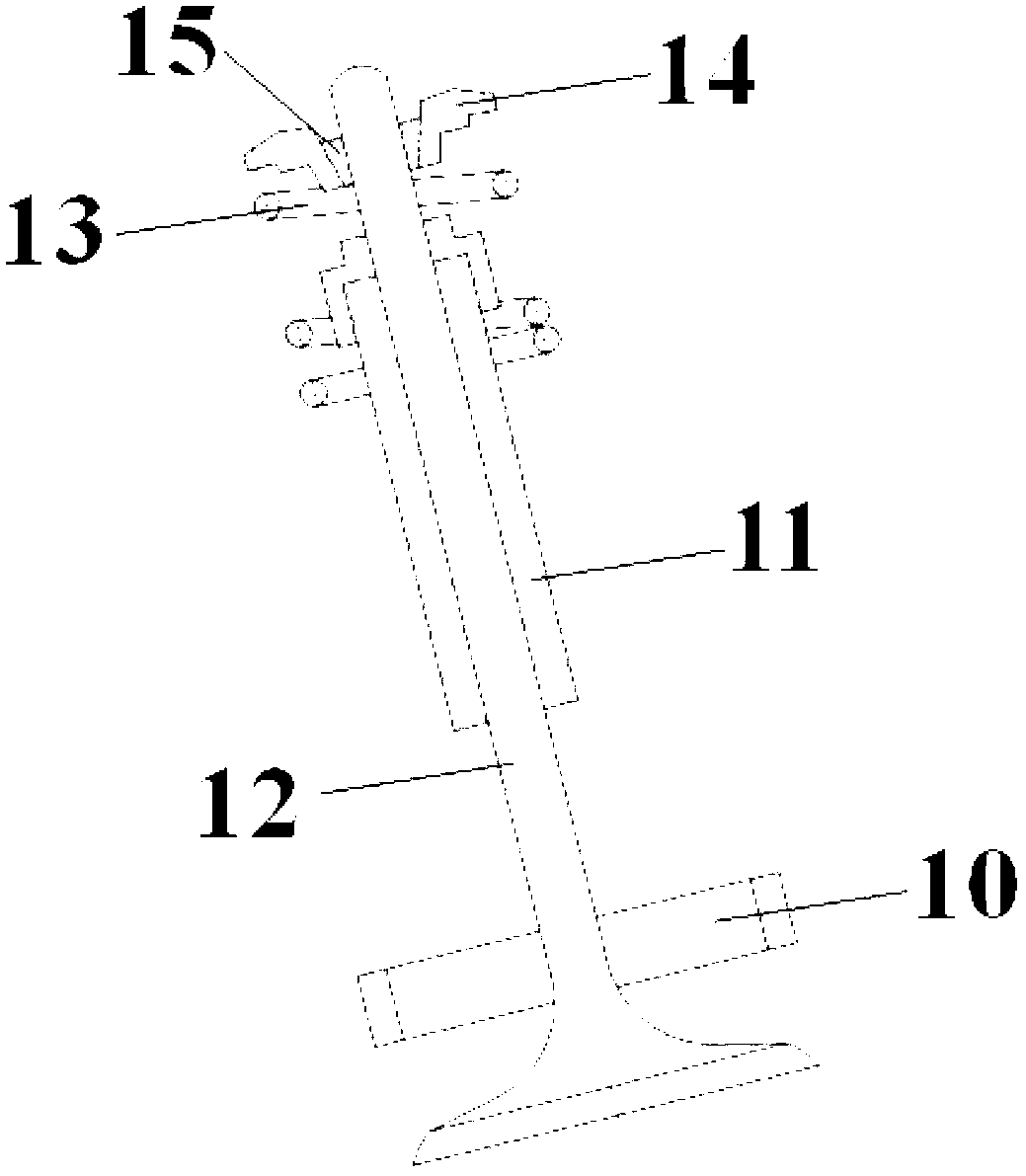

[0023] figure 1 It is the overall assembly drawing of the present invention, and it can be seen that a novel variable valve lift adjustment system of the present invention is mainly composed of a valve train 1, a valve train 2, a hydraulic clearance adjuster 3 and a power source 4 for the adjuster. The finger rocker arm 21 in the valve train 2 uses the hydraulic lash adjuster 3 as a fulcrum, and the rotation of the camshaft 22 drives the finger rocker arm 21 to swing, thereby realizing the opening and closing of the valve mechanism 1 . When the speed of the vehicle changes, the control system controls the stepper motor 41 in the regulator power source 4 to drive the gear 40 to rotate, and through the meshing of the rack and pinion, the position of the hydraulic gap adjuster 3 is continuously and accurately adjusted, that is, the position in the lever is changed. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com