Brake disk of motor vehicle

A technology for brake discs and motor vehicles, applied in the field of brake discs, can solve the problems of easy deformation and scrapping of brake discs, influence of brake disc strength, high cost, etc., and achieve the effect of good ventilation and heat dissipation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

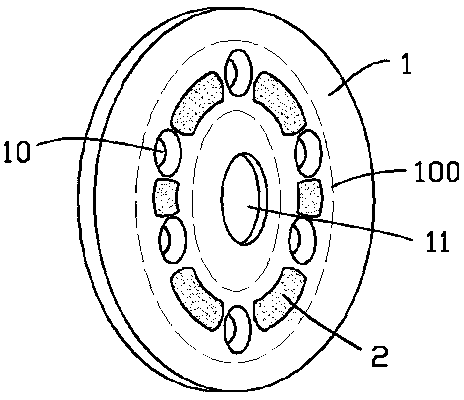

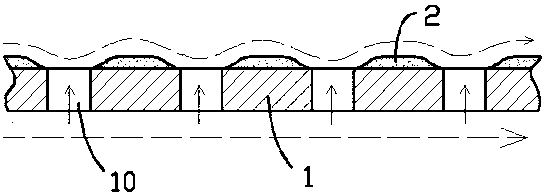

[0021] figure 1 Shown is the first embodiment of the present invention, wherein the motor vehicle brake disc includes a circular disc body 1, the center of the disc body 1 is provided with an axle fitting hole 11, and the disc body 1 is evenly provided with heat dissipation holes throughout the disc body 1 along the circumferential direction. Holes 10; on one side of the disc body 1, on the annular belt 100 formed by the heat dissipation holes 10, every other heat dissipation hole 10 is provided with a protuberance 2 with a streamlined surface; the annular belt 100, which can be approximately regarded as being surrounded by the common inner and outer tangent lines of the cooling holes 10; Note: figure 1 For the sake of clarity in the drawing, the annular zone 100 is drawn farther away from the enveloping line.

[0022] In this embodiment, the heat dissipation hole 10 is a circular hole, and the projected shape of the raised body 2 relative to the disk body 1 is adapted to the...

Embodiment 2

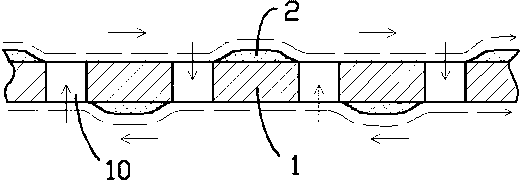

[0027] image 3 Shown is the second embodiment of the present invention. Since the first embodiment has been described in detail, only the expanded view of the brake disc is given in the second embodiment and explained. In the second embodiment, the machine The motor vehicle brake disc includes a circular disc body 1, and the disc body 1 is evenly provided with cooling holes 10 passing through the disc body along the circumferential direction; Above, every second heat dissipation hole 10 is provided with a protruding body 2 with a streamlined surface, and the positions of the protruding bodies 2 on both sides of the disc body 1 are arranged alternately.

[0028] The specific shapes of the heat dissipation holes 10 and the bumps 2 can be equivalent to those of the first embodiment.

[0029] The principle of Embodiment 2 is set forth below: when the brake disc rotates with the wheel at high speed, the airflow on the annular belts on both sides of the disc body 1 will flow throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com