Method and device for detecting atomic force microscopic scanning of tri-scanner atomic

A technique of atomic force microscopy and scanning detection, applied in scanning probe microscopy, measuring devices, scanning probe technology, etc., which can solve the problem of sacrificing imaging resolution or accuracy, unable to achieve high-resolution scanning imaging at the same time, and unable to simultaneously Achieving large-scale, large-mass samples and large-scale scanning measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

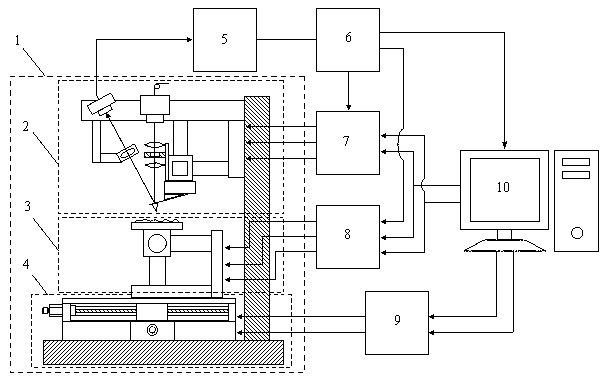

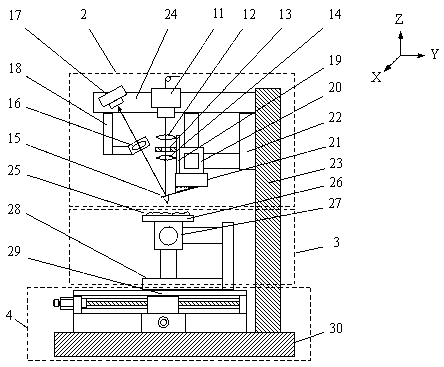

[0012] The three-scanner atomic force microscopy detection method is a detection method that combines sample scanning and probe scanning, introduces a stacked piezoelectric ceramic scanner, scanning tracking optical path and feedback tracking optical path, and uses sample fixation, microprobe scanning and The method of feedback realizes the micro-nano detection of various samples with a resolution of 0.1nm and a scanning range of 10-100 μm; introduces a tubular piezoelectric ceramic scanner to realize 1- to Micro-nano detection with a scanning range of 10 μm; the introduction of a two-dimensional stepping scanning table to scan samples, and the Z-direction feedback control and feedback tracking optical path of micro-probes with laminated piezoelectric ceramics, in the way of micro-probe feedback and sample scanning Realize 0.1nm resolution of large and heavy samples, image scanning and stitching in the range of 0.1~1mm.

[0013] The present invention adopts the method of combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com