A series-wound motor

A series-excited motor and rear-end cover technology, applied in the field of machinery, can solve the problems of separation, carbon brushes cannot work normally, copper inserts are separated, etc., and achieves extended service life, convenient processing, installation and removal, and is not easy to move axially. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

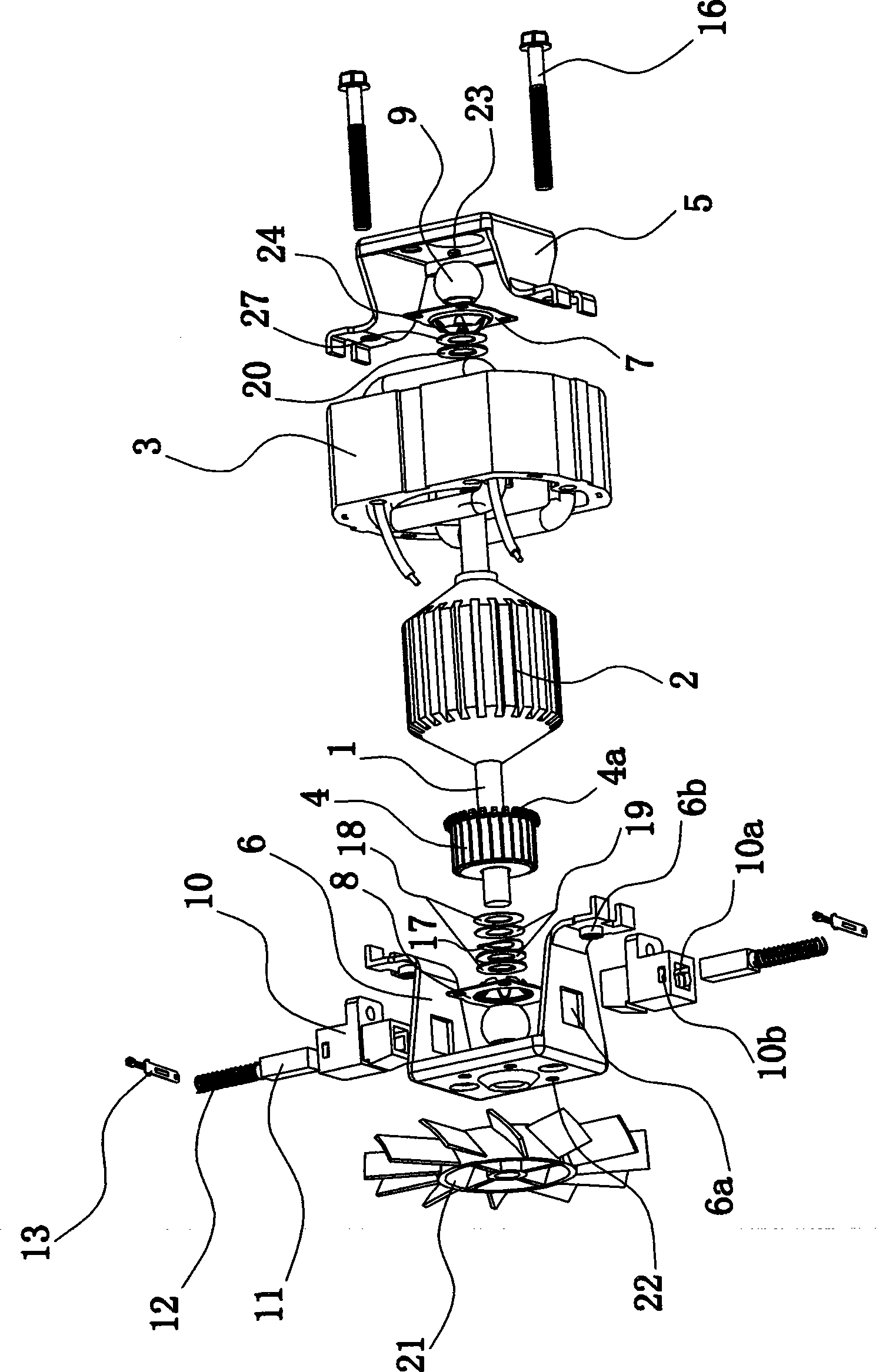

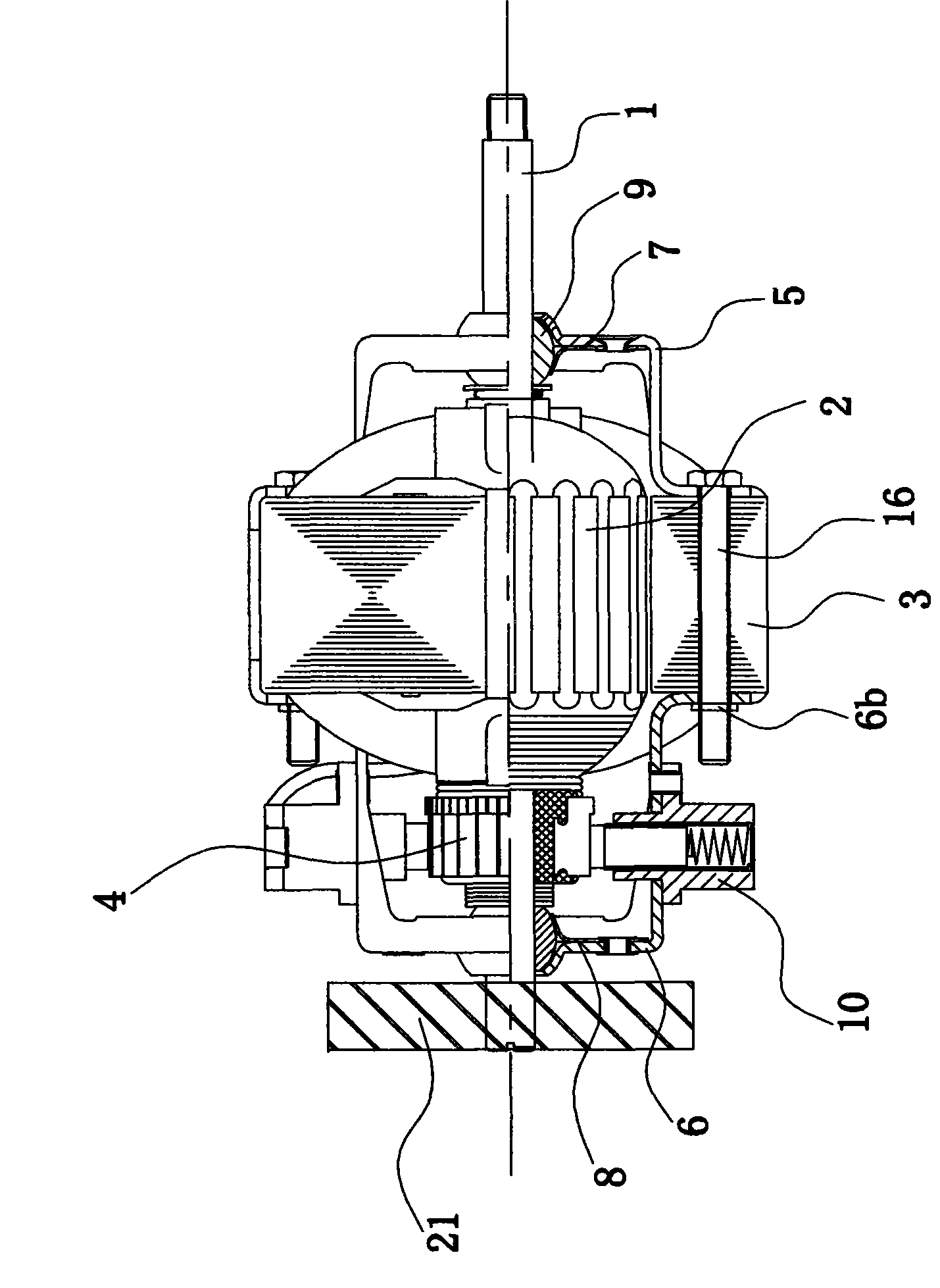

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

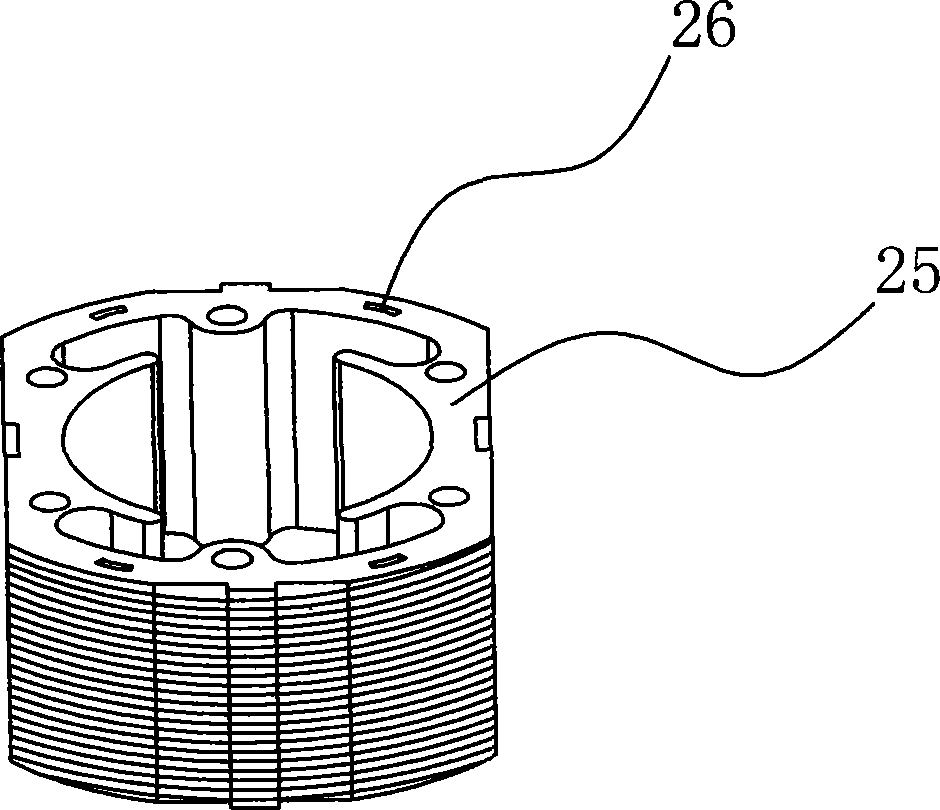

[0027] like figure 1 and 2 As shown, the series-excited motor includes a rotating shaft 1, carbon brushes, a rotor 2, a stator 3, a commutator 4, and front and rear end covers 5, 6, and the rotor 2, stator 3 and commutator are sleeved on the rotating shaft 1. 4 is located between the front and rear end covers 5, 6 and the rotor 2 is located in the stator 3, the commutator 4 is located between the rotor 2 and the rear end cover 6, the front and rear end covers 5, 6 are fixedly connected to the stator 3, The inboards of front and rear end covers 5 and 6 are fixedly connected with front and rear bearing sleeves 7 and 8 respectively, and bearings 9 are respectively installed between front and rear bearing sleeves 7 and 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com