Moulded skin and method for producing moulded skin

A technology of skinning and molding, applied in the direction of household components, applications, coatings, etc., which can solve problems such as stone washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

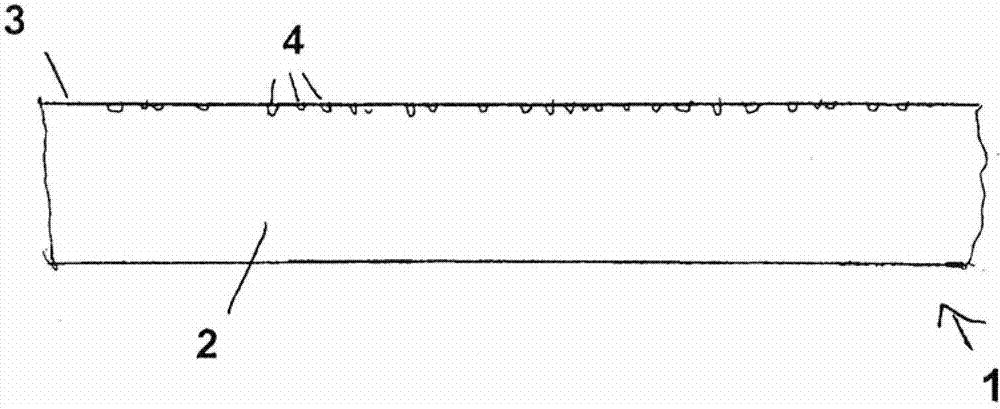

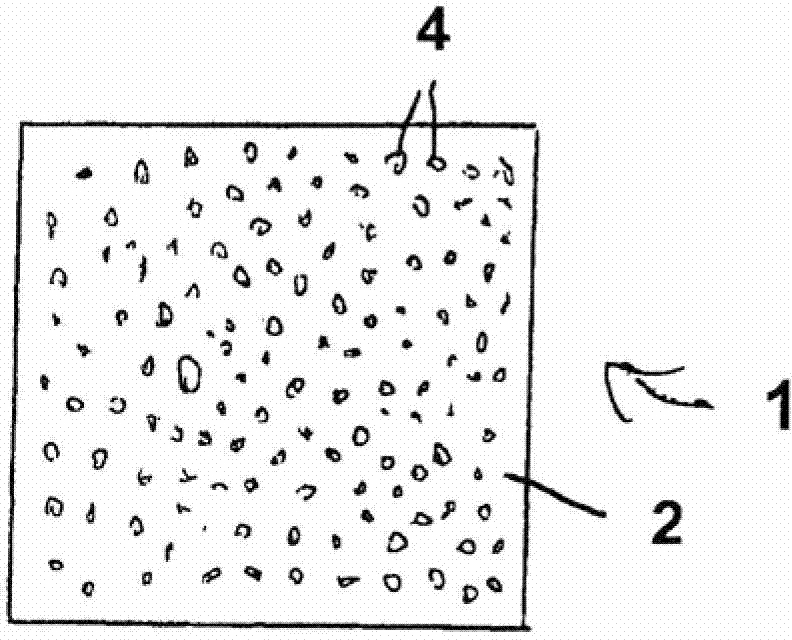

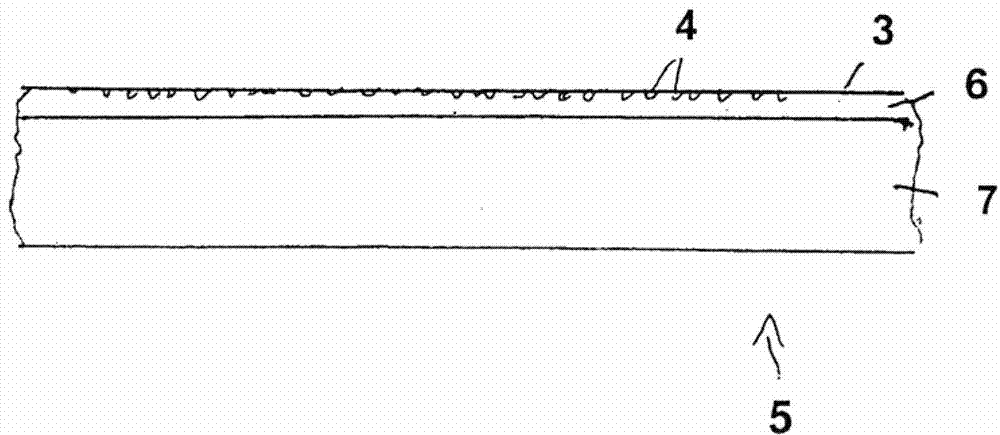

[0032] figure 1 An enlarged detail view of a molded skin 1 according to a first embodiment of the invention is shown. The molded skin has a single-layer structure and comprises a layer 2 with a surface 3 . Layer 2 in this embodiment is approximately 1.2 mm thick and comprises plastisol of the first colour. In the hardened state, the plastisol has a Shore A hardness of 71. Plastisol spots 4 have been introduced into surface 3 of layer 2 . In the top view of the molded skin 1 part of the layer 2 and part of the spot 4 can be seen. The plastisol spots 4 have a different color than the plastisol layer 2 . Thus presenting the visual effect of a high-quality appearance.

[0033] The surface of the molded skin 1 is smooth and may in alternative embodiments have a leather-like grainy surface structure. The surface structure is however independent of the applied plastisol spots 4 , ie the plastisol spots are molded into the surface and do not form raised portions deviating from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com