Variable valve gear for internal combustion engine

An internal combustion engine, variable technology, applied in valve devices, valve drive devices, mechanical equipment, etc., can solve problems such as the inability of the threaded part to be compactly designed, the responsiveness of the variable valve device is deteriorated, and the abnormal wear between parts, etc., to achieve compact size. , The effect of preventing abnormal wear and inhibiting the increase of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

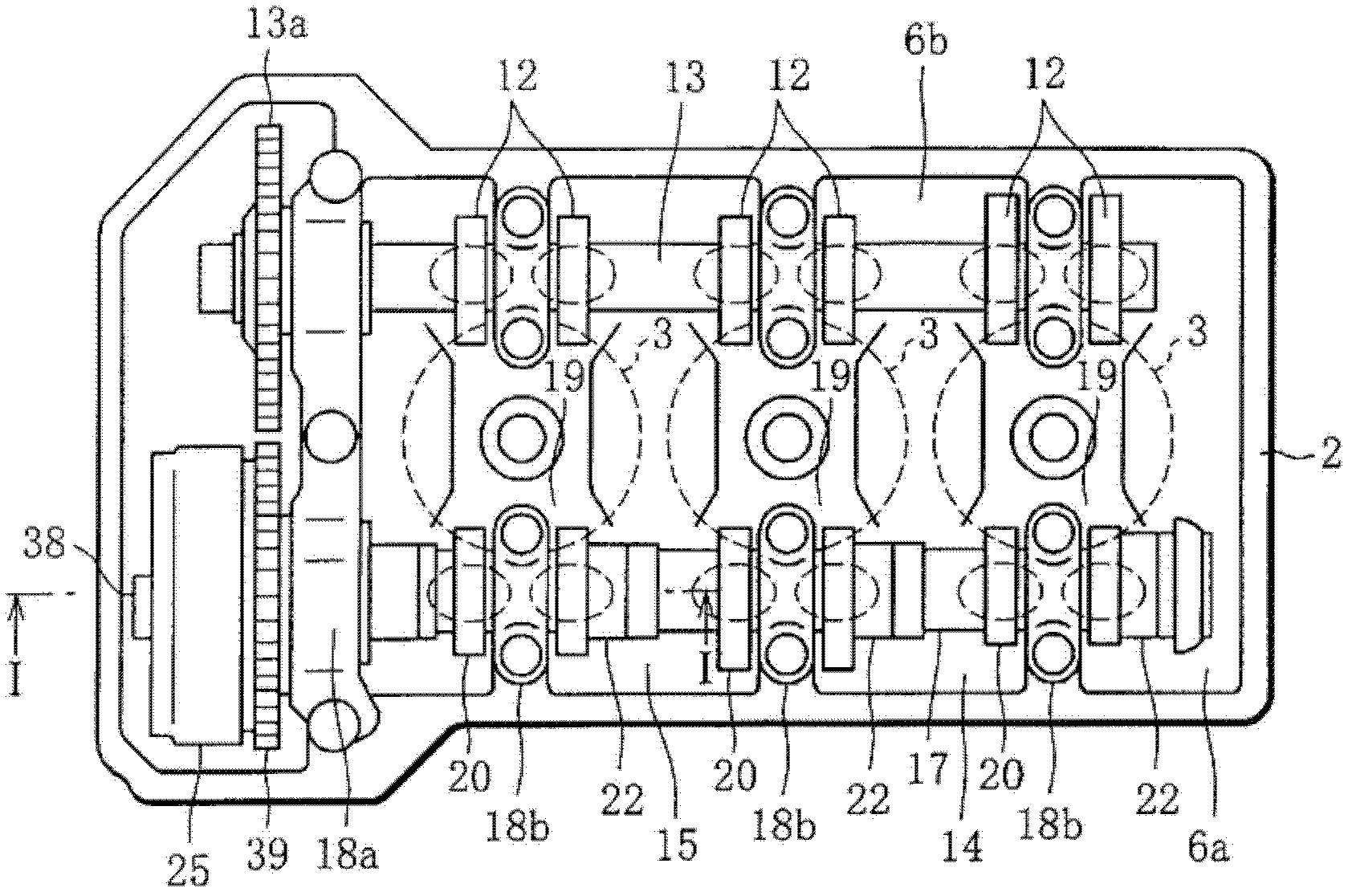

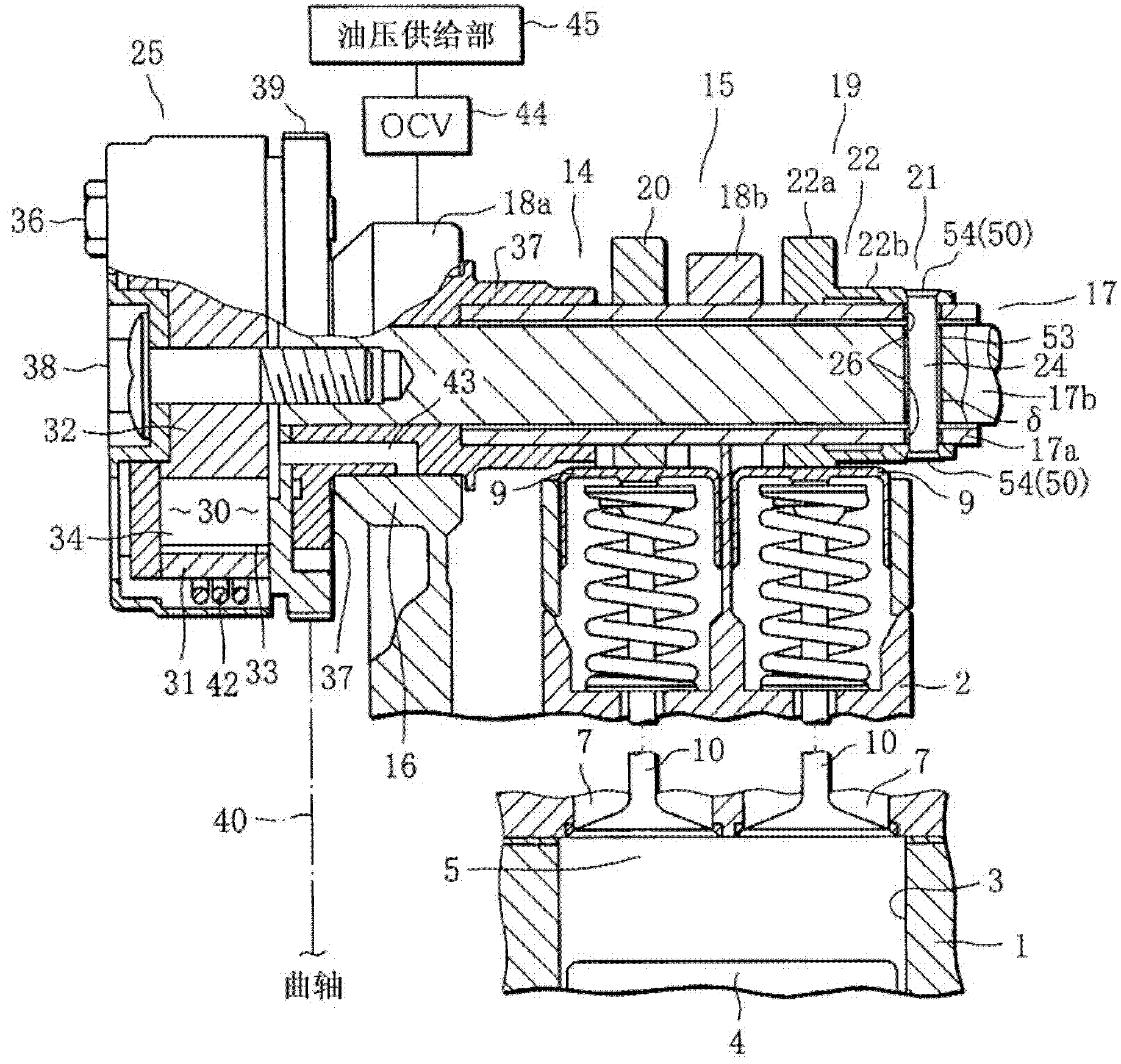

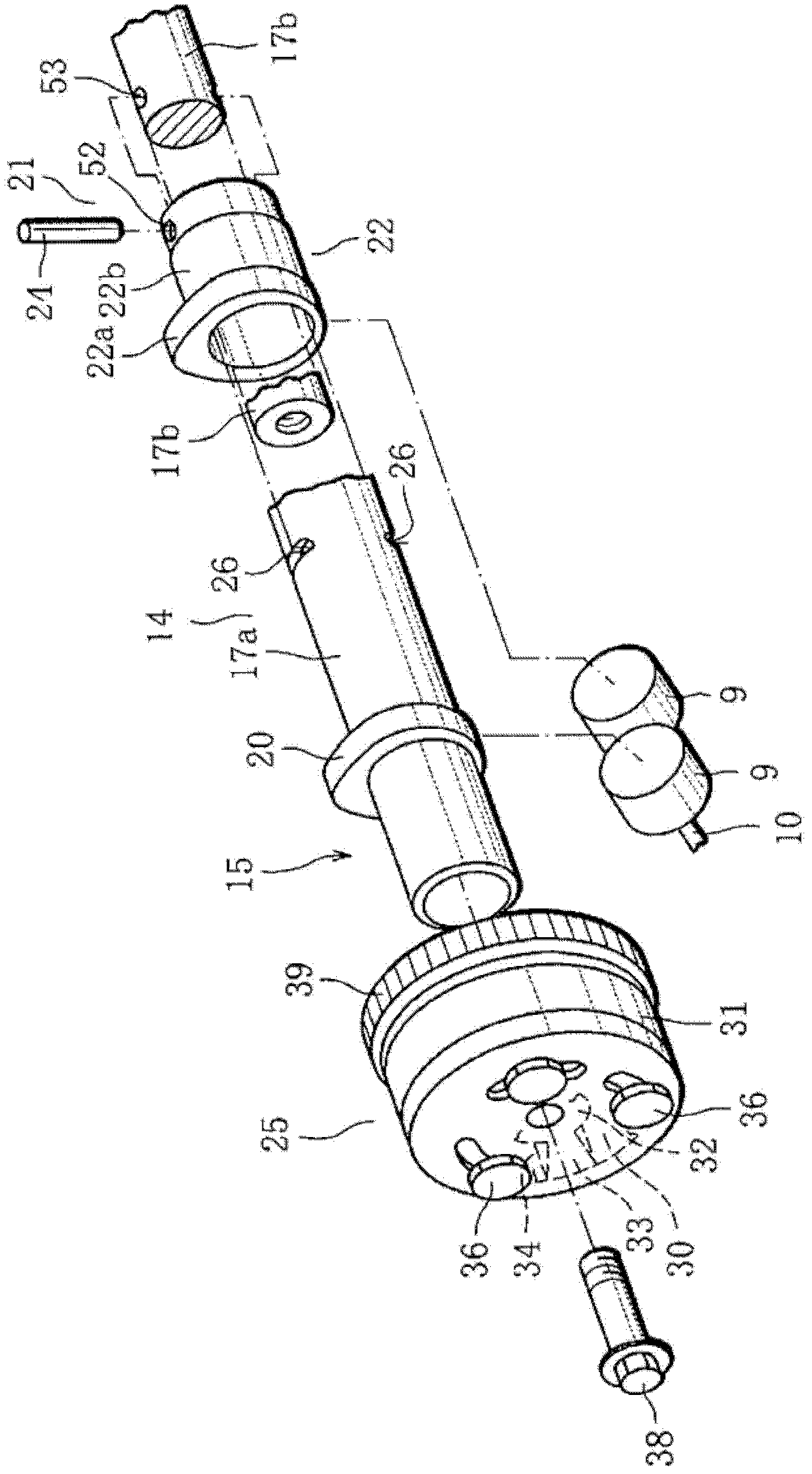

[0066] Below, according to Figure 1 to Figure 5 The present invention will be described with reference to the first embodiment shown.

[0067] figure 1 A plane representing an internal combustion engine, such as a three-cylinder (multiple cylinders) reciprocating engine (hereinafter simply referred to as an engine), figure 2 means along figure 1 In the cross section of line II in the figure, 1 in the figure is the cylinder block of the engine, and 2 is the cylinder head mounted on the head of the cylinder block 1.

[0068] Among them, such as figure 1 and figure 2 As shown, three cylinders 3 (only partial cylinders are shown) are formed on the cylinder block 1 along the front-rear direction of the engine. Each of these cylinders 3 accommodates reciprocating pistons 4 (only figure 2 icon).

[0069] Combustion chambers 5 corresponding to the respective cylinders 3 are formed on the lower surface of the cylinder head 2 . A pair of intake ports 7 (two) for intake and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com