Power transmission device

A technology of power transmission device and power transmission mechanism, applied in the direction of transmission device, transmission belt, transmission element or rope or cable for pulley, etc., can solve problems such as poor durability, and achieve the effect of easy manufacture and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

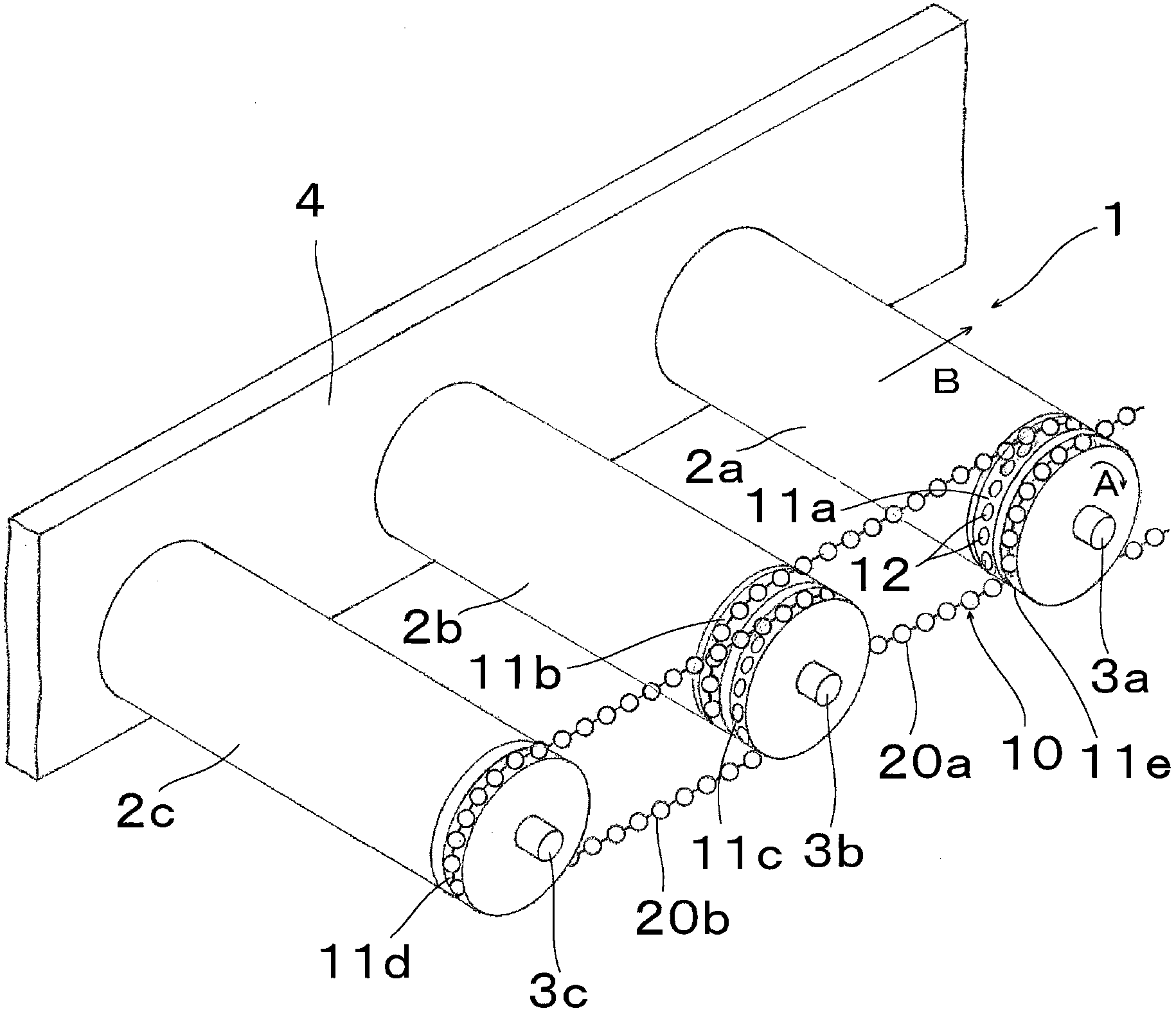

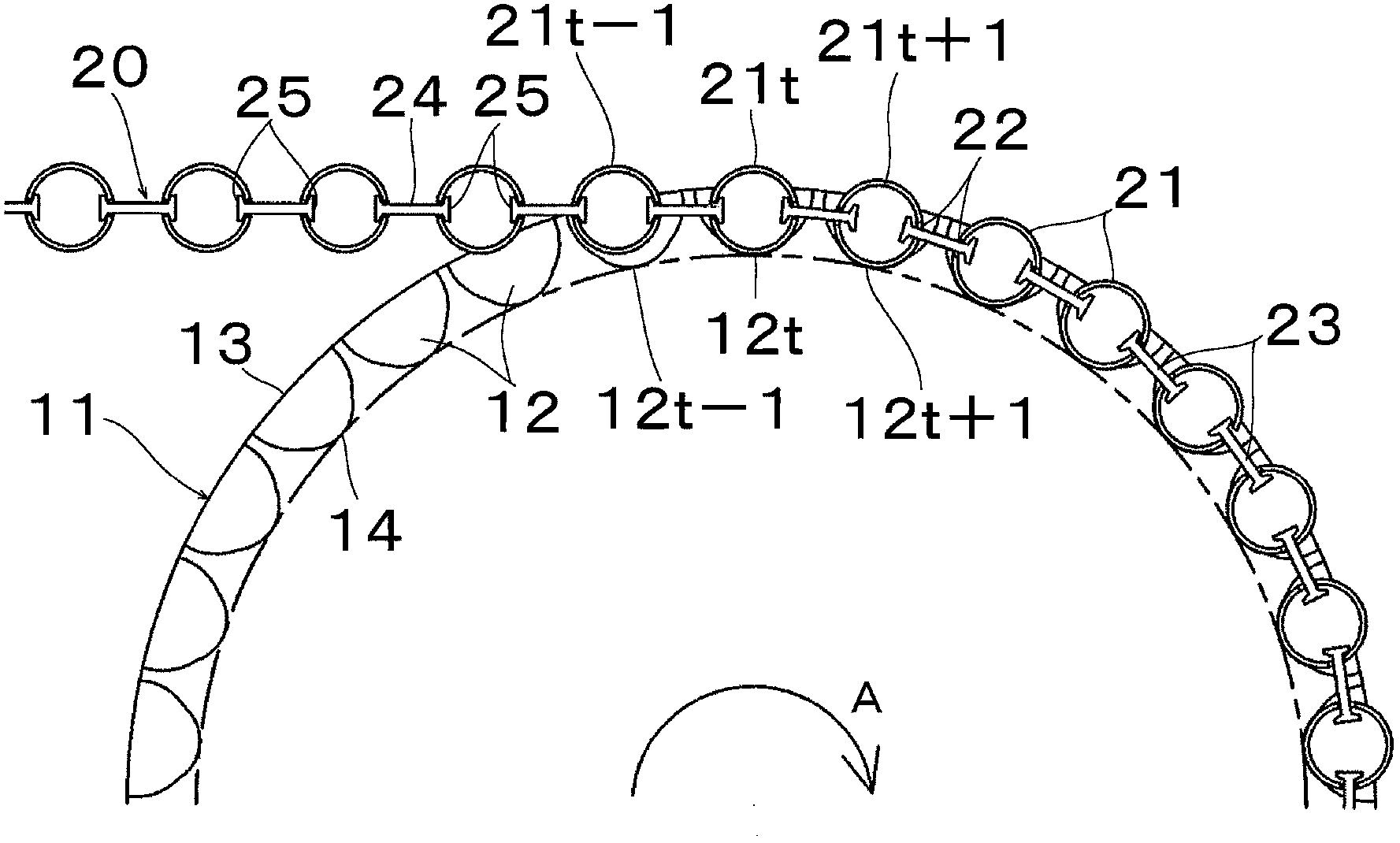

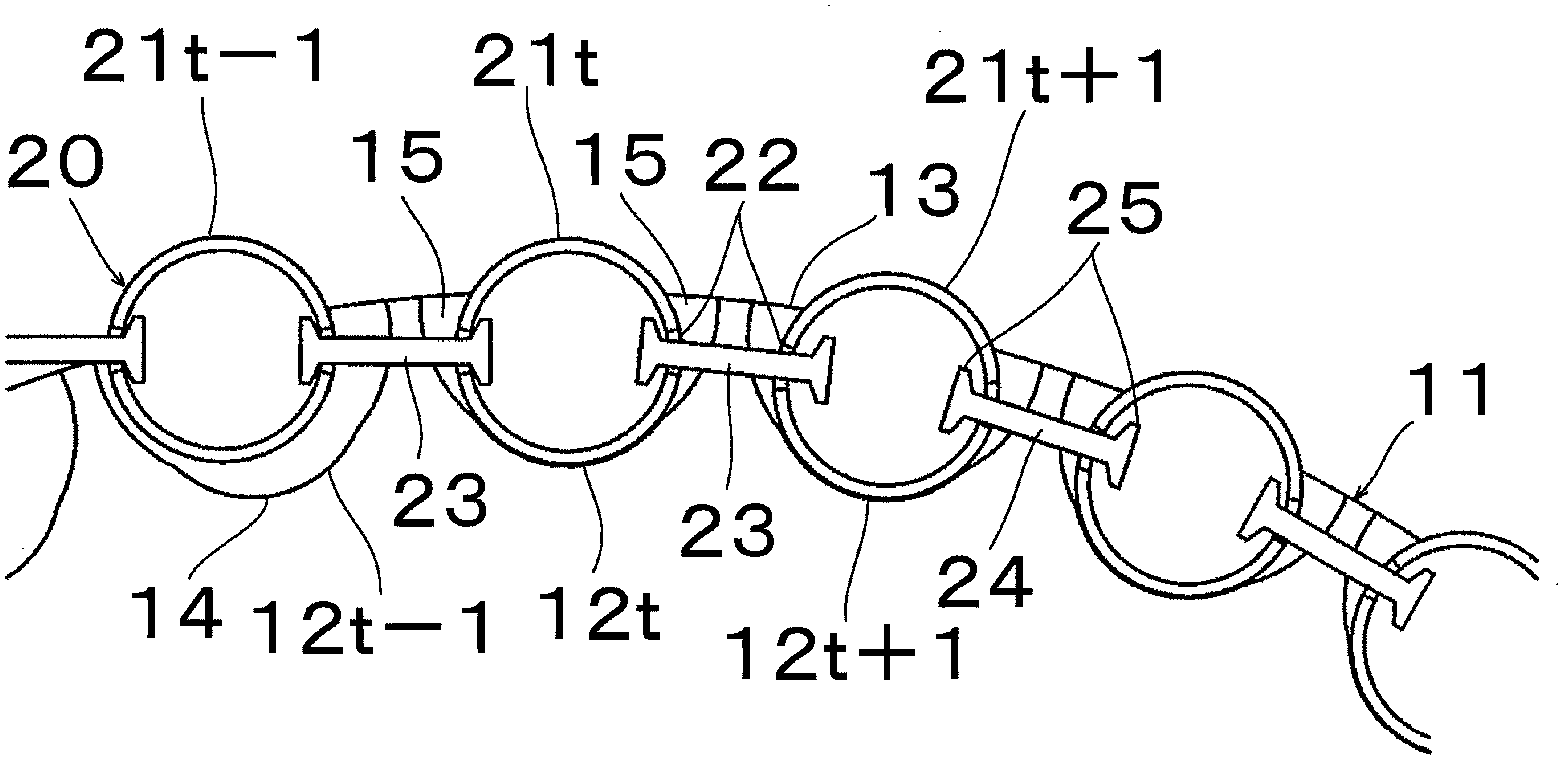

[0017] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 It is a perspective view schematically showing a part of a conveyor 1 incorporating a power transmission device 10 according to an embodiment of the present invention. Conveyor 1 comprises: many cylindrical roller bodies 2a, 2b, 2c (in figure 1 For the convenience of illustration, only the three rollers are shown with a larger interval than usual), which are arranged in a manner that their respective axes are parallel to each other; the left and right side plates 4 (in figure 1 Only one side plate is shown in the figure), which supports both ends of the rotating shafts 3a, 3b, 3c of the roller bodies 2a, 2b, 2c to be rotatable by means of bearings (not shown); the power transmission device 10, which It is for transmitting the rotational power of the roller body 2a rotationally driven by the motor not shown to the roller bodies 2b and 2c. The roller bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com