Coil form for mounting on a magnet core, magnet core for reluctance resolvers, and method of manufacture

A coil frame and magnetic core technology, which is applied to the shape/style/structure of magnetic circuits, electromechanical devices, and winding insulation, can solve problems such as unfavorable welding processing of components, and achieve the effect of high retention force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

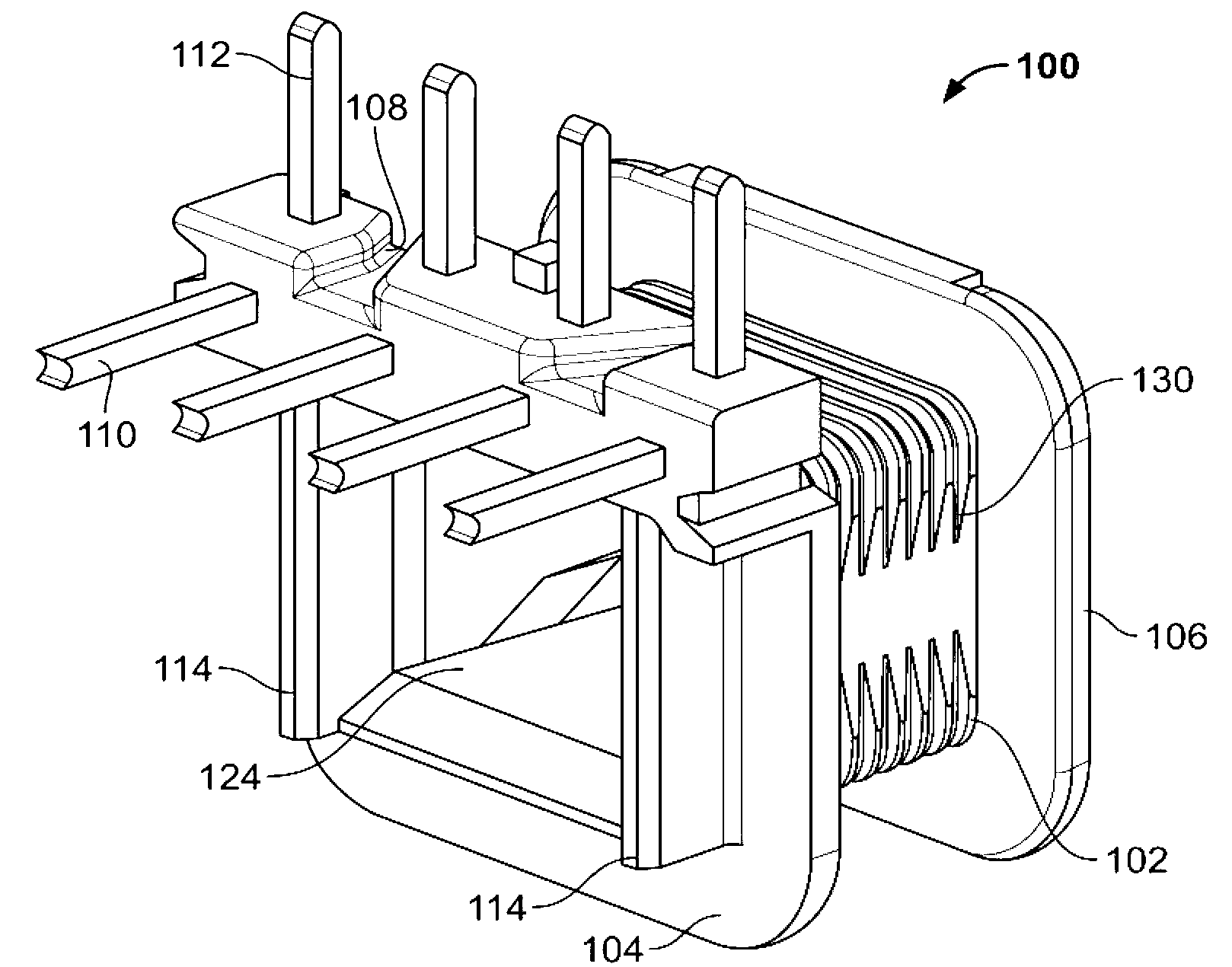

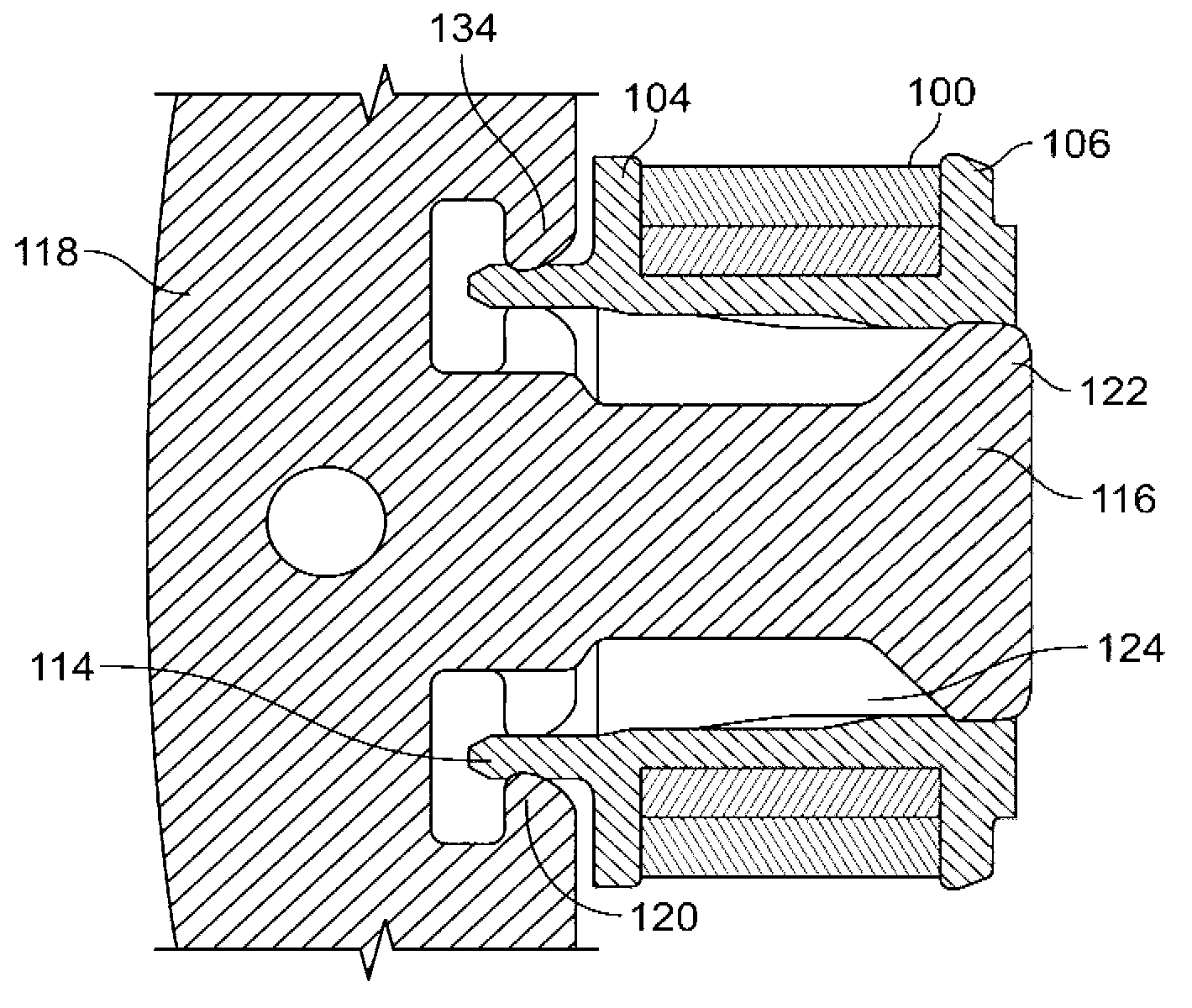

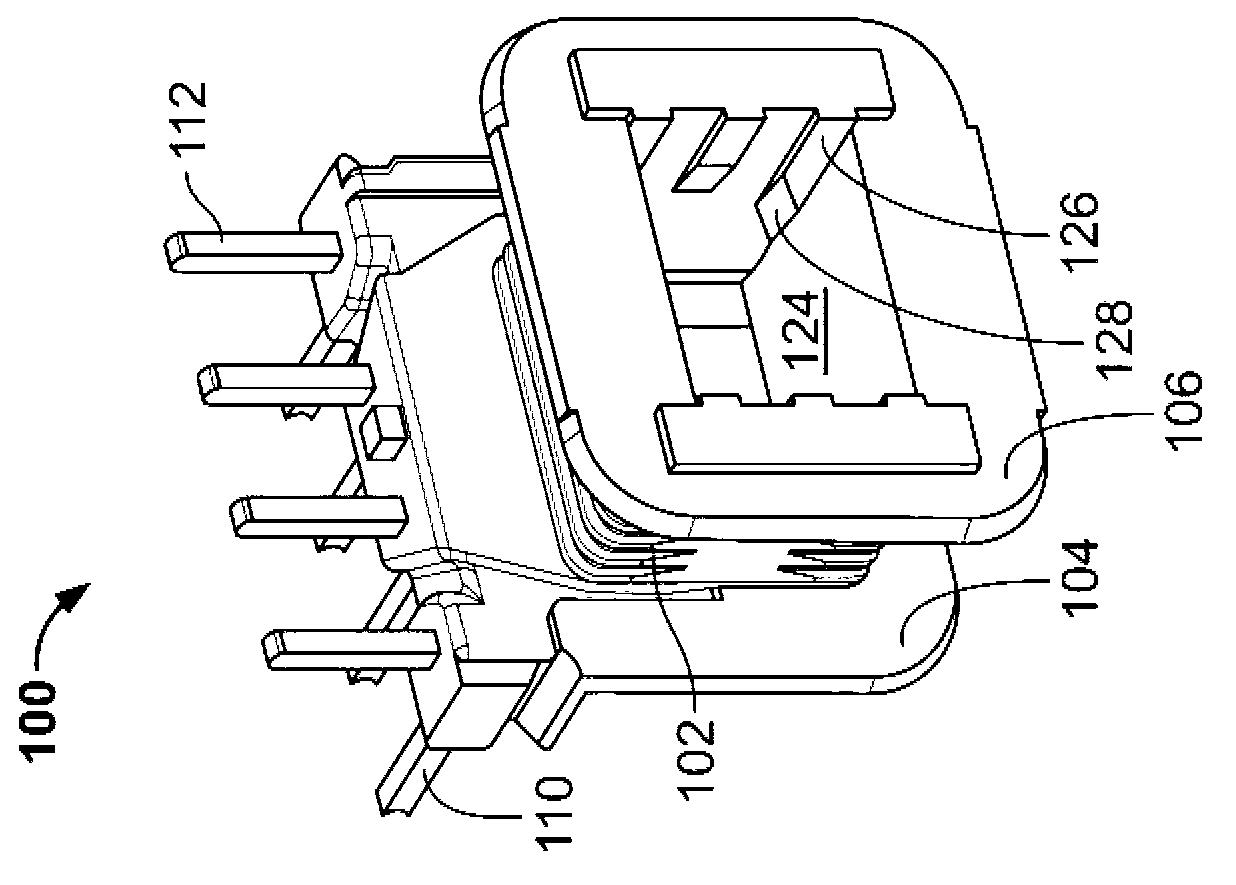

[0059] In the following, advantageous embodiments of the invention are described in more detail with reference to the accompanying drawings. In this regard, it should be noted that although a magnetic core which may be used as a stator of a reluctance solver is always presented below, the invention is naturally applicable to any type of rotating electrical equipment. This means that the type of fastening according to the invention of the coil former can also be used for electric machines and motors, both on the stator core and on the rotor core.

[0060] Further, the invention is not limited to those embodiments in which the teeth of the magnetic core protrude back inwardly from the annular yoke towards the central axis; the magnetic core teeth placed on the outer periphery of the magnetic core can also be arranged correspondingly in an equivalently similar manner There is a bobbin according to the invention.

[0061] Finally, the coil former according to the invention can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com