Plant rooting agent composition

The technology of a rooting agent and a composition is applied in the field of compositions for inducing rooting of plants, and can solve the problems of inconvenience of use, inactivation of the degree of activity, large volume of liquid preparations and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

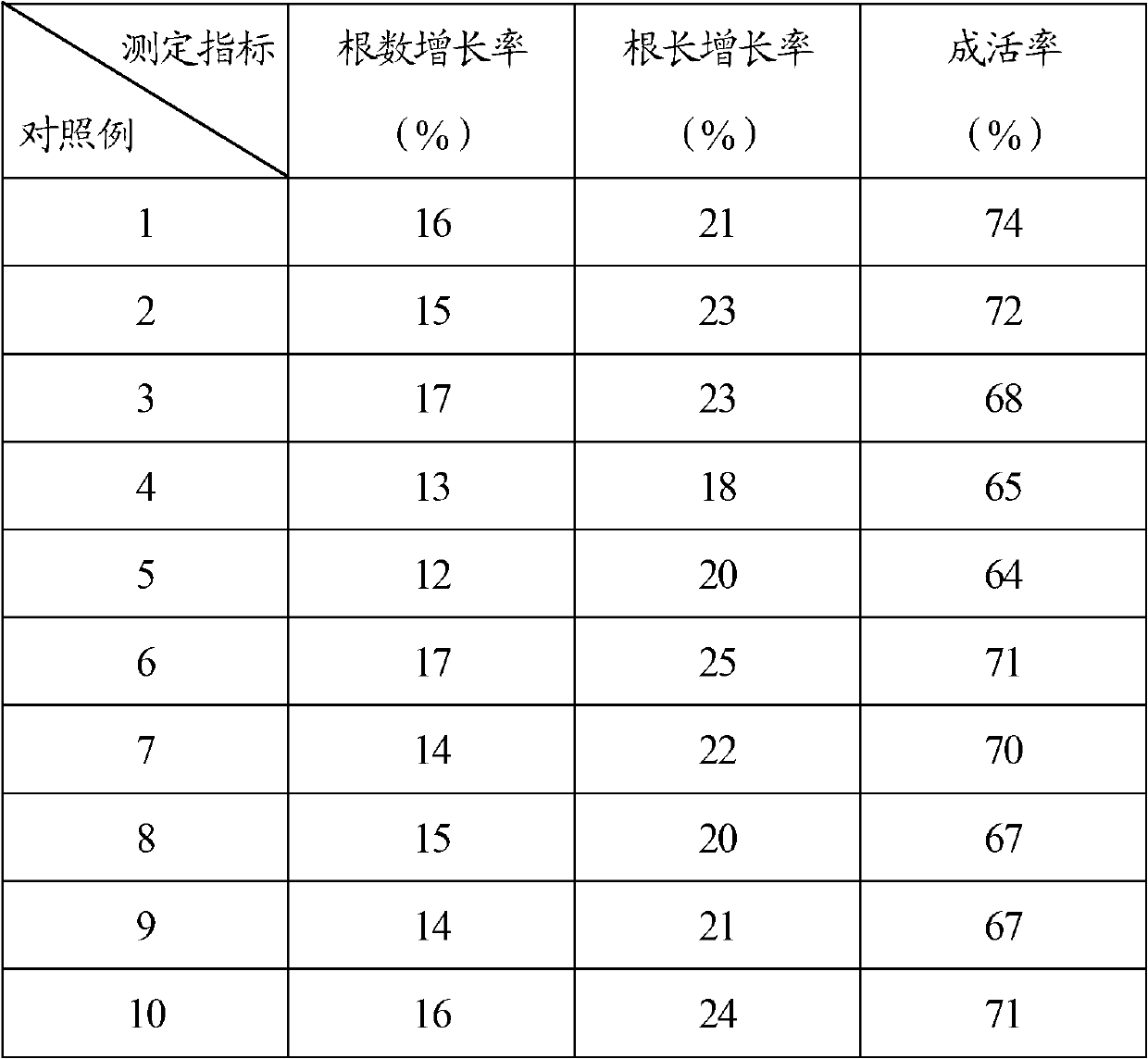

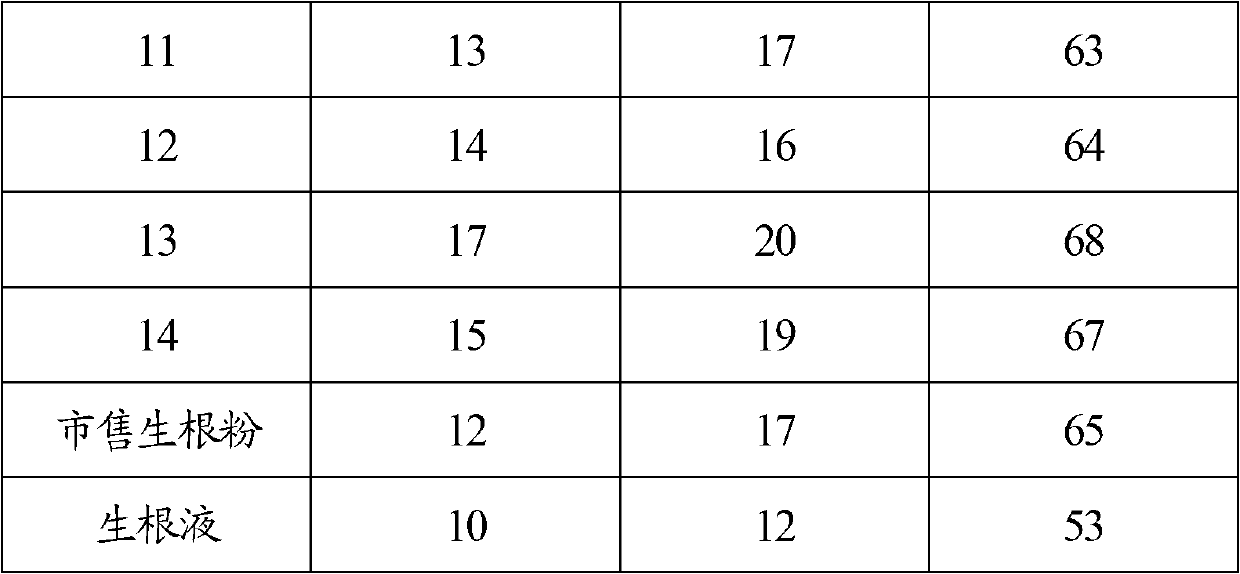

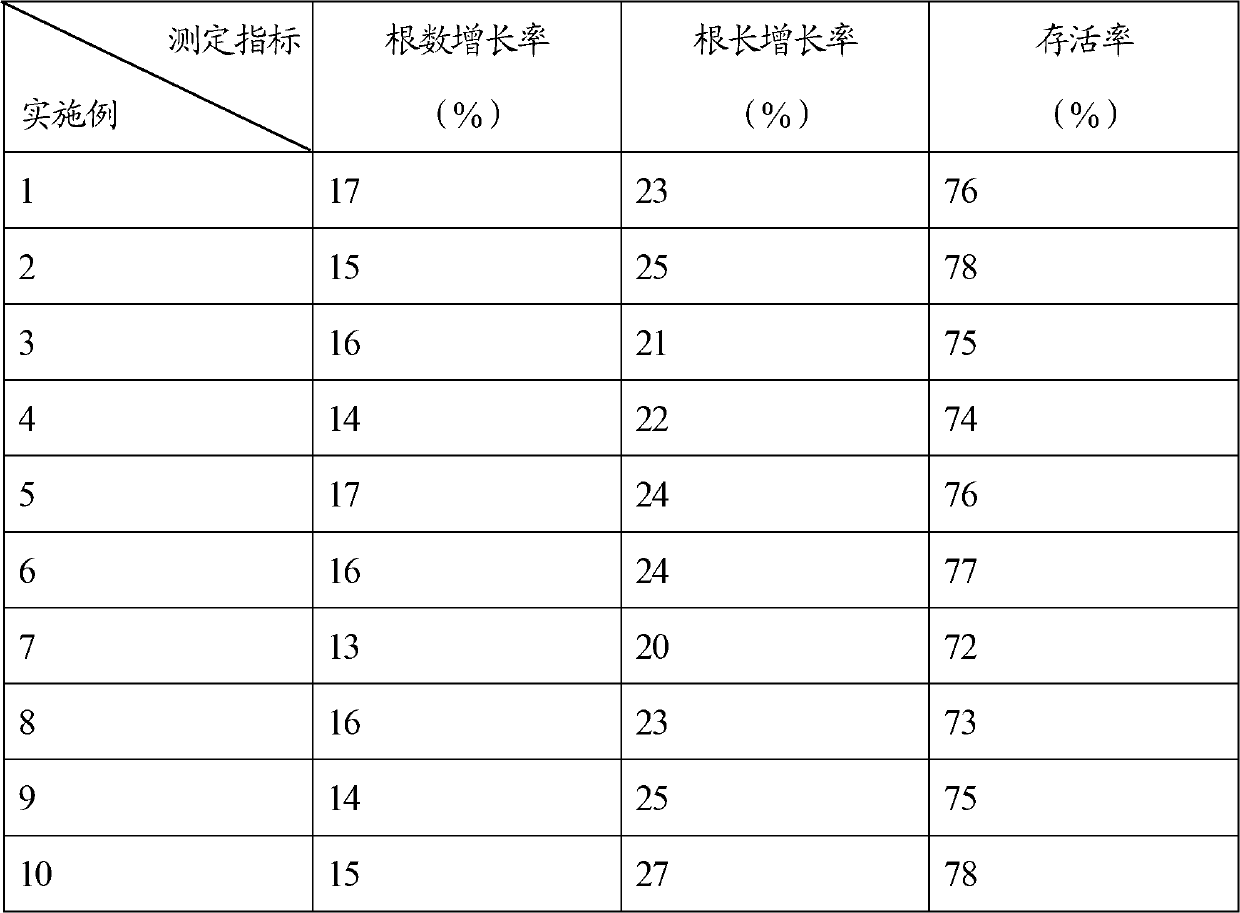

Examples

Embodiment 1

[0118] Weigh each substance according to the following ratio:

[0119] Alpha Naphthaleneacetic Acid - 0.01%; Indolebutyric Acid - 2%; Boric Acid - 5%; the remainder is Lubricant-1, Disintegrant-1 and Filler-1.

[0120] After the above-mentioned substances are weighed according to the proportion, they are pulverized, mixed and granulated according to the existing method for preparing granules to prepare granular Example 1, and the gained Example 1 is sprinkled on the soil of newly transplanted plant camphor saplings After five months, measure the survival rate of its root number growth rate, root length growth rate, drought resistance index and camphor seedlings.

Embodiment 2

[0122] Weigh each substance according to the following ratio:

[0123] α-naphthaleneacetic acid - 0.01%; indole butyric acid - 9%; boric acid - 5%; the rest is colorant-1, lubricant-2, disintegrant-2 and filler-1.

[0124] After the above-mentioned substances are weighed according to the proportion, they are pulverized, mixed and granulated according to the existing method for preparing granules to obtain granular Example 2, and the gained Example 2 is sprinkled on the soil of newly transplanted plant camphor saplings After five months, measure the survival rate of its root number growth rate, root length growth rate, drought resistance index and camphor seedlings.

Embodiment 3

[0126] Weigh each substance according to the following ratio:

[0127] α-naphthaleneacetic acid - 1%; indolebutyric acid - 9%; boric acid - 5%; the rest are disintegrant-1 and filler-1.

[0128] After the above-mentioned materials are weighed according to the proportioning amount, pulverize, mix and granulate according to the existing method for preparing granules to obtain blocky embodiment 3, and the gained embodiment 3 is buried in the soil of newly transplanted plant sycamore saplings, Measure the survival rate of its root number growth rate, root length growth rate, drought resistance index and camphor seedlings after five months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com