Synchronous clawing mechanism with multiple manipulators

A technology of manipulators and manipulators, which is applied in the field of multi-manipulator synchronous grasping mechanism, can solve problems such as low operating efficiency and easy instability, and achieve the effects of improving operating efficiency, perfecting functions, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

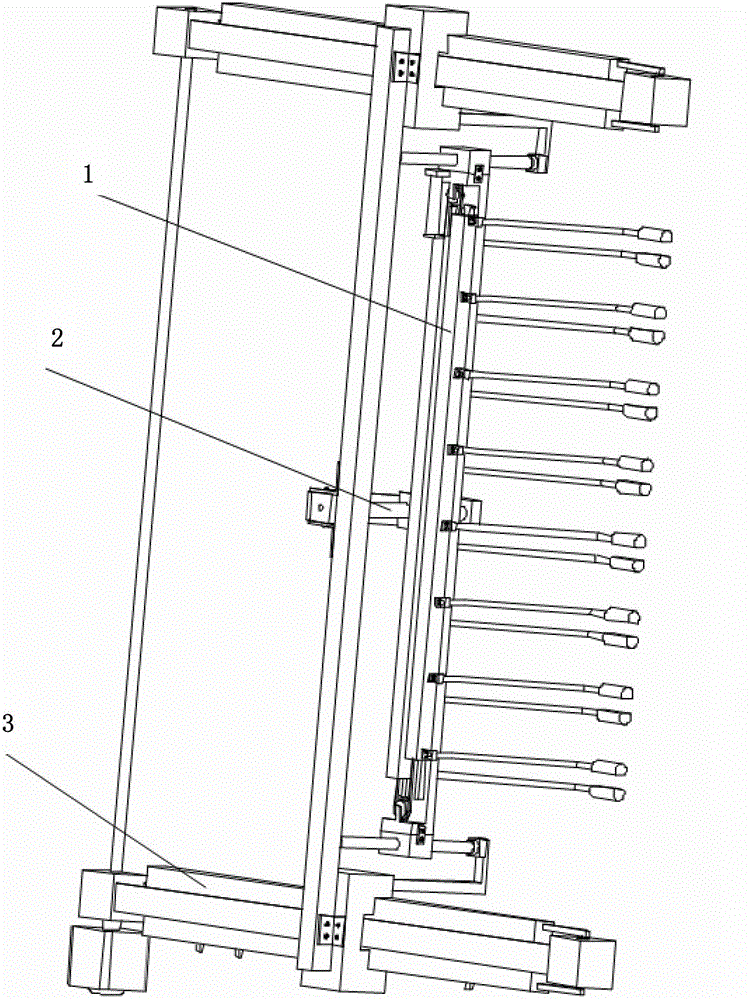

[0021] Such as figure 1 As shown, the present invention mainly includes a manipulator synchronously grasping platform 1, a synchronous frame vertical lifting platform 2, and a synchronous frame laterally moving platform 3.

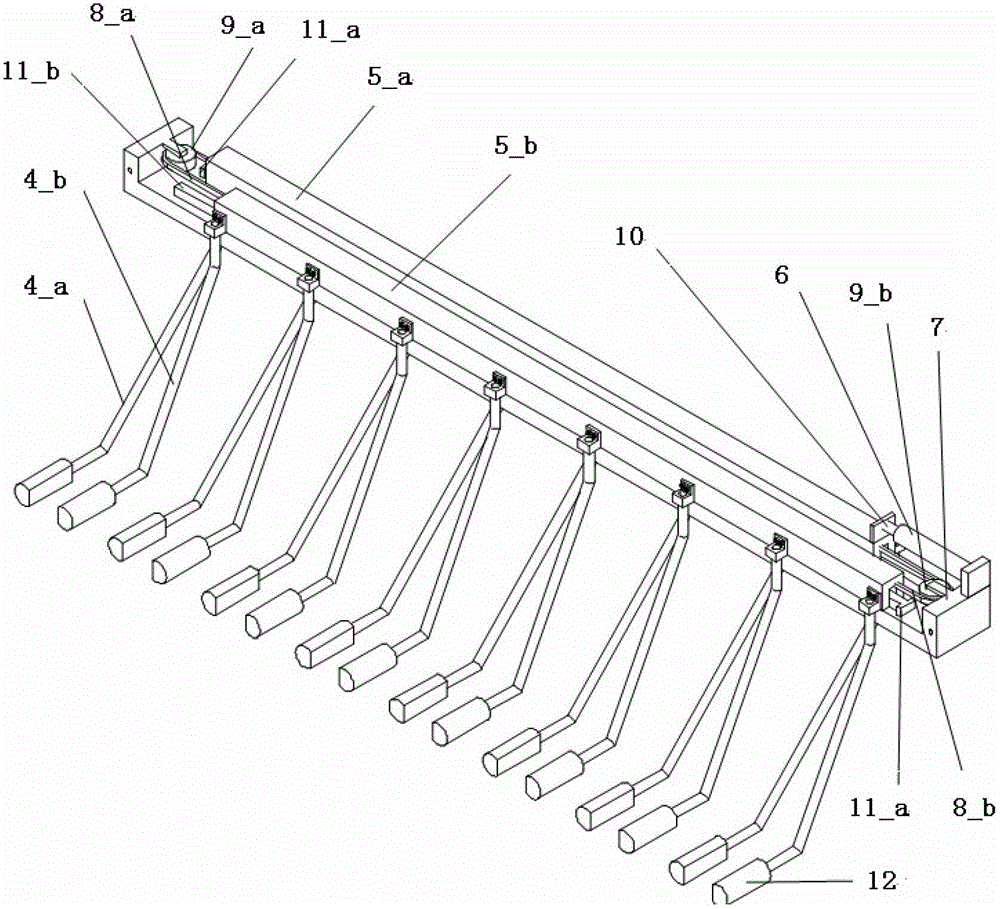

[0022] Such as figure 2 As shown, one group of manipulators 4 is divided into left manipulator 4_a and right manipulator 4_b, there are 8 groups of manipulators 4 in the figure, left manipulator 4_a is fixed on the synchronization device slider 5_a, right manipulator 4_b is fixed on the synchronization device slider 5_b on. Cylinder 6 is fixed on the synchronous frame 7, and cylinder 6 drives synchronous device slide block 5-a motion, and stay cord 8 is connected together with two synchronous device slide blocks 5 left and right ends respectively by small pulley 9. When the manipulator 4 needs to clamp the work object, the cylinder piston 10 retrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com