Heat treatment method of high-chromium martensitic stainless steel

A heat treatment method, high-chromium martensite technology, applied in the field of stainless steel heat treatment, can solve the problems of oil pollution, easy fire, and low safety factor in the production site of heat treatment furnaces, and achieve the goals of avoiding cracking of workpieces, eliminating quenching stress, and reducing quenching stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

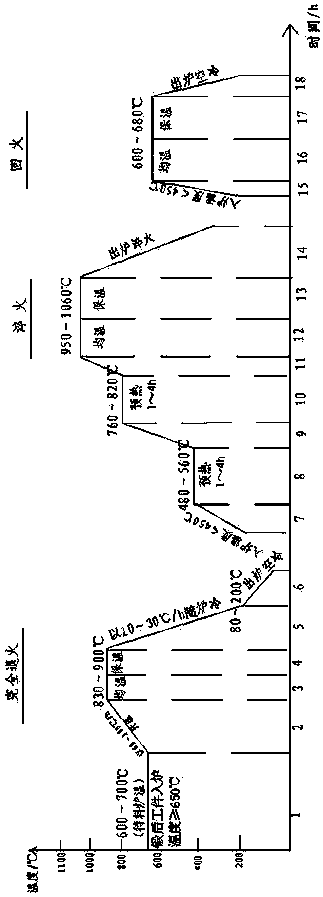

[0019] A heat treatment method for high chromium martensitic stainless steel, the method is as follows:

[0020] 1) Annealing

[0021] Put the forged stainless steel workpiece into the furnace at a surface temperature of 650°C, put it into a furnace at 700°C, and raise the temperature to 830°C at a heating rate of 100°C / h, and the holding time is 2.3 to 2.7 hours / 100mm Calculation, that is, calculate the holding time according to the length of the workpiece. After the holding is over, cool down with the furnace at a cooling rate of 30°C / h to 80-200°C and leave the furnace for air cooling;

[0022] 2) Preheat

[0023] After the annealing process, the stainless steel forgings are preheated twice at the furnace temperature of 300°C. The first preheating temperature is 560°C, and the holding time is 4h. The second preheating temperature is 820°C, and the holding time is 4h;

[0024] 3) Quenching

[0025] After twice preheating, the quenching temperature of the forging is 1060°C...

Embodiment 2

[0029] A heat treatment method for high chromium martensitic stainless steel, the method is as follows:

[0030] 1) Annealing

[0031] Put the forged stainless steel workpiece into the furnace at 700°C at a furnace temperature of 700°C, and raise the temperature to 830°C at a heating rate of 60°C / h. The holding time is calculated at 2.3 to 2.7 hours / 100mm. After the heat preservation is over, cool down with the furnace at a cooling rate of 10°C / h to 80°C and leave the furnace for air cooling;

[0032] 2) Preheat

[0033] The stainless steel forgings that have undergone the annealing process are preheated twice at a furnace temperature of 400°C. The first preheating temperature is 480°C, and the holding time is 1h. The second preheating temperature is 760°C, and the holding time is 1h;

[0034] 3) Quenching

[0035] After twice preheating, the forging is quenched at a quenching temperature of 950°C and the holding time is 0.8 to 1.3 hours / 100mm, so that the center of the wor...

Embodiment 3

[0039] A heat treatment method for high chromium martensitic stainless steel, the method is as follows:

[0040] 1) Annealing

[0041] Put the forged stainless steel workpiece into the furnace at 660°C at the furnace temperature of 660°C, and heat it up to 850°C at a heating rate of 80°C / h. The holding time is calculated at 2.3 to 2.7 hours / 100mm. After the heat preservation is over, cool down with the furnace to 140°C at a cooling rate of 20°C / h and leave the furnace for air cooling;

[0042] 2) Preheat

[0043] After the annealing process, the stainless steel forgings are preheated twice at a furnace temperature of 100°C. The first preheating temperature is 520°C, and the holding time is 2.5h. The second preheating temperature is 790°C, and the holding time is 2.5h;

[0044] 3) Quenching

[0045] After twice preheating, the forgings are quenched at a quenching temperature of 1000°C and the holding time is 0.8 to 1.3 hours / 100mm, so that the central part of the workpiece r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com