Construction method for piling prestressed concrete hollow pile into thick-layer soft soil processed by cement mixing piles

A technology of cement mixing piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increasing pile foundation settlement, reducing pile foundation bearing capacity, reducing pile bearing capacity, etc., and achieves the reduction of foundation Effects of settlement, ensuring stability, and improving foundation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

[0013] The stratum distribution and soil characteristics of the site: the upper part is 19m thick layer of soft soil, the lower part is 6m silty clay, and the lower part is silt layer, which can be used as the bearing layer of pile foundation.

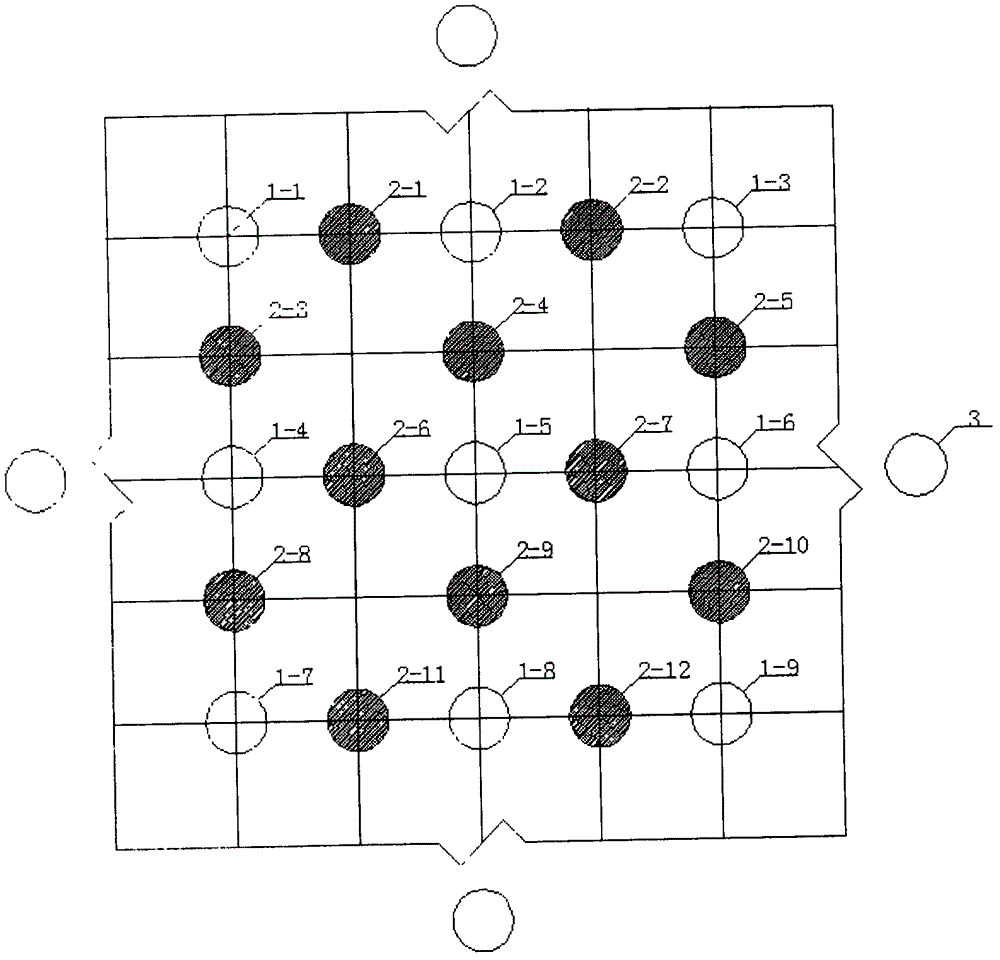

[0014] Project overview: A 4-story comprehensive building is proposed to be built on the above-mentioned site, with a frame structure and a site area of 15mX50m. The pre-designed prestressed concrete hollow piles are driven in. The pile length is 28m, the pile diameter is 0.5m, and the pile spacing is 2.5m.

[0015] The specific process of piling construction according to the above geological conditions and engineering requirements is as follows: set up precipitation wells around the site, using a large diameter of 0.5m, with a distance of 15m and a depth of 20m, a total of nine wells. After setting the dewatering well, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com