SAGD (steam assisted gravity drainage) wet steam injection station system, boiler water recycling method thereof

A technology of wet steam and steam injection, which is applied in the field of SAGD wet steam injection station system, can solve the problems of inability to realize energy saving, water saving and low thermal efficiency, so as to improve the utilization of heat and overcome the effect of low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

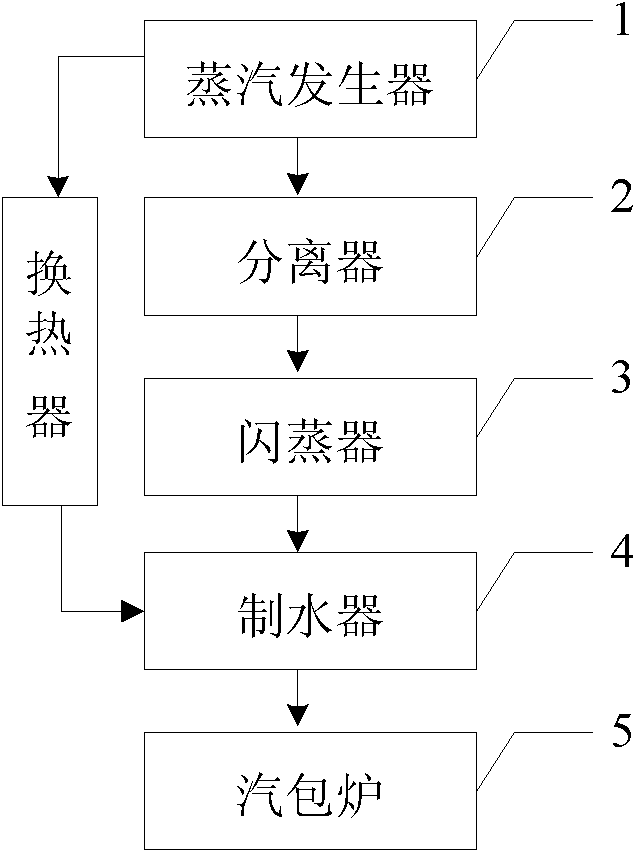

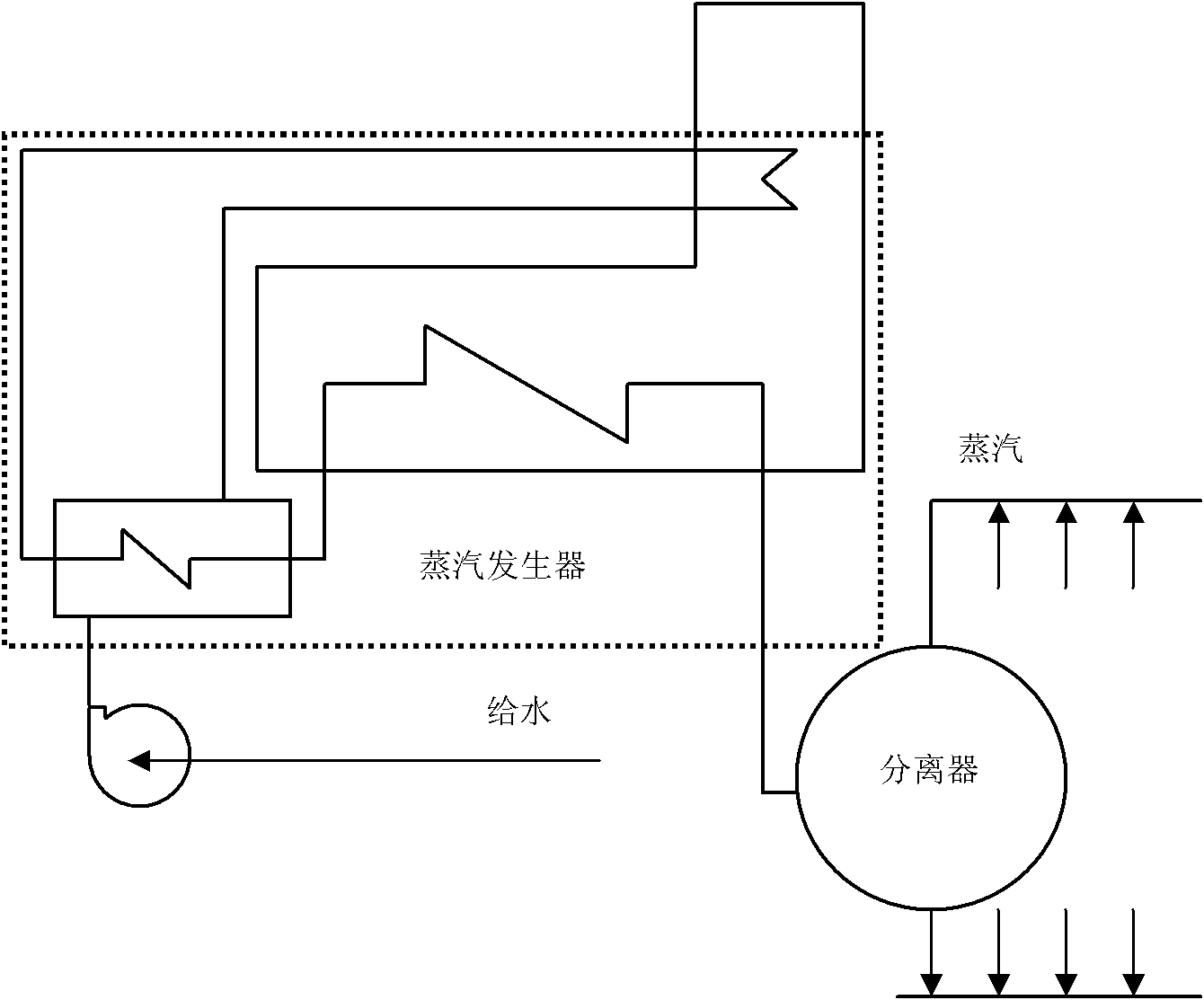

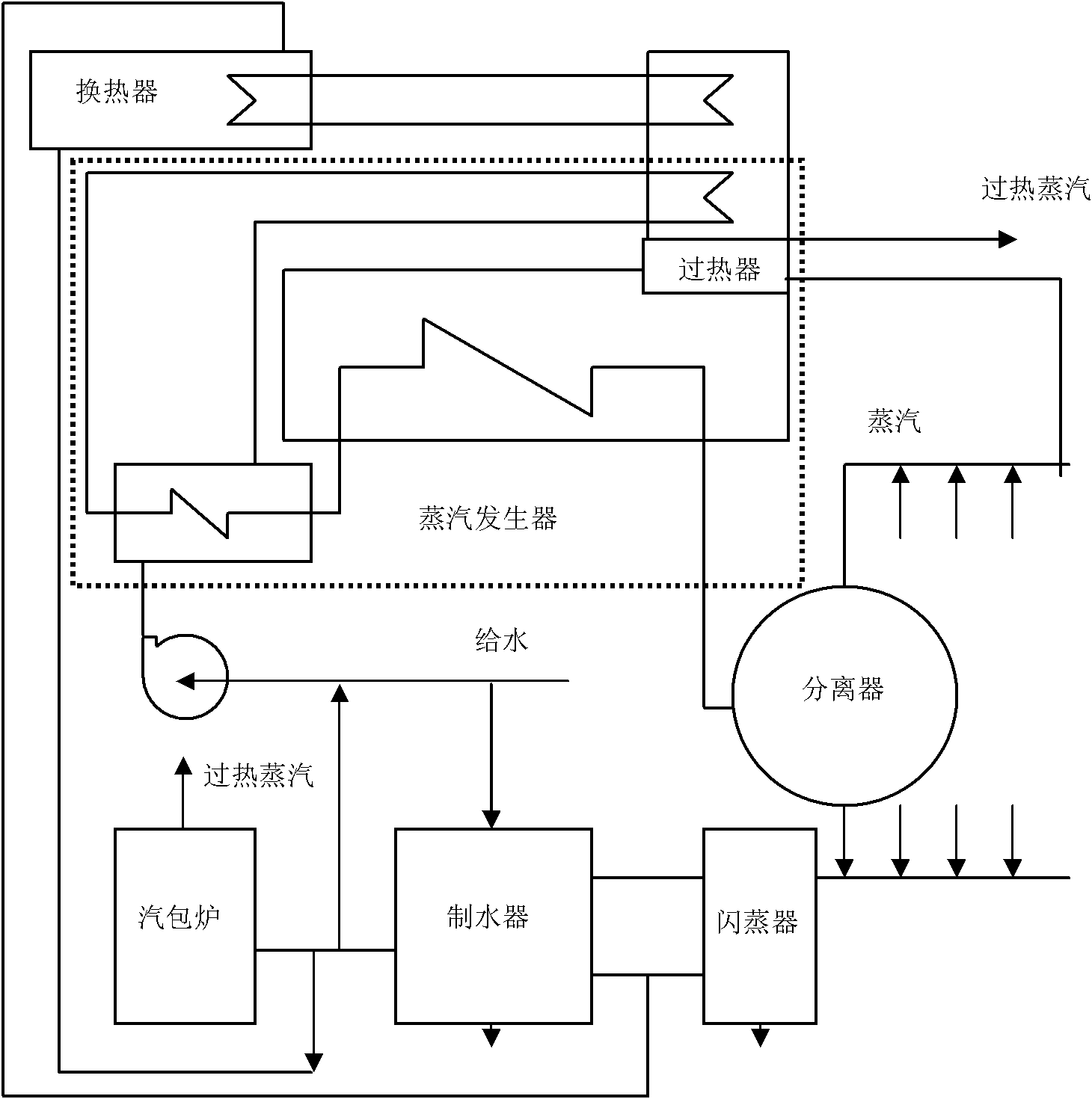

[0018] Embodiments of the present invention provide a SAGD wet steam injection station system, such as figure 1 As shown, the system includes: a steam generator 1, a separator 2, a flash evaporator 3, a water maker 4, a drum boiler 5, and a heat exchanger 6, wherein the steam generator 1, the separator 2, the flash evaporator 3, The water generator 4 and the drum boiler 5 are connected sequentially, and the heat exchanger 6 is respectively connected to the steam generator 1 and the water generator 4. The working principle of the SAGD wet steam injection station system will be described in detail below.

[0019] The separator separates the high-dryness steam and high-temperature brine output from the boiler. The flash evaporator is used to flash the high-temperature brine separated by the separator to generate wet steam and high-concentration brine. The water generator is used to convert the wet steam generated by the flash evaporator to The product water generated by evaporati...

Embodiment 2

[0031] The embodiment of the present invention also provides a boiler water recycling method based on the SAGD wet steam injection station system, Figure 4 is the flowchart of the method, such as Figure 4 As shown, the method includes:

[0032] Step 401, separating the high-quality steam and high-temperature brine output by the boiler;

[0033] Step 402, flashing the separated high-temperature brine to generate wet steam and high-concentration brine;

[0034] Step 403, performing evaporative desalination treatment on the high-concentration brine produced by the flash treatment with the wet steam produced by the flash treatment to produce finished water;

[0035] Step 404, heating the generated product water into superheated steam;

[0036]Step 405, recovering the waste heat of the flue gas generated by the SAGD wet steam injection station system as a supplementary heat source for evaporative desalination treatment.

[0037] By reprocessing the high-temperature brine outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com