Liquid lubricating system specially used for high-speed bearing

A liquid-lubricated, high-speed bearing technology, applied in the field of space and aviation bearing lubrication, can solve the problems of complex structure, large impact force of bearings, and increased strength requirements of parts, and achieves simplified bearing lubrication system, simplified supply system, The effect of flexible bearing arrangements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

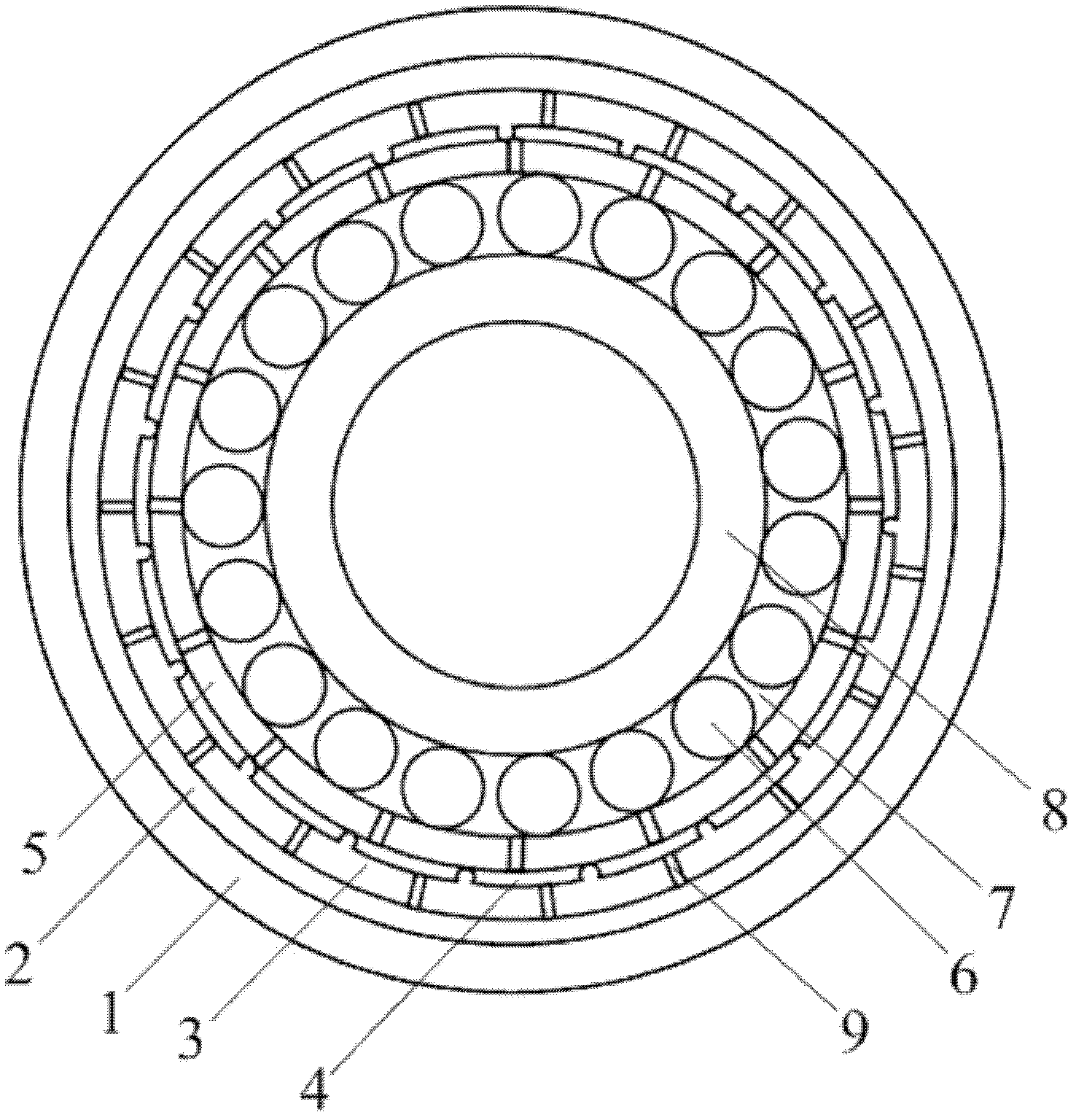

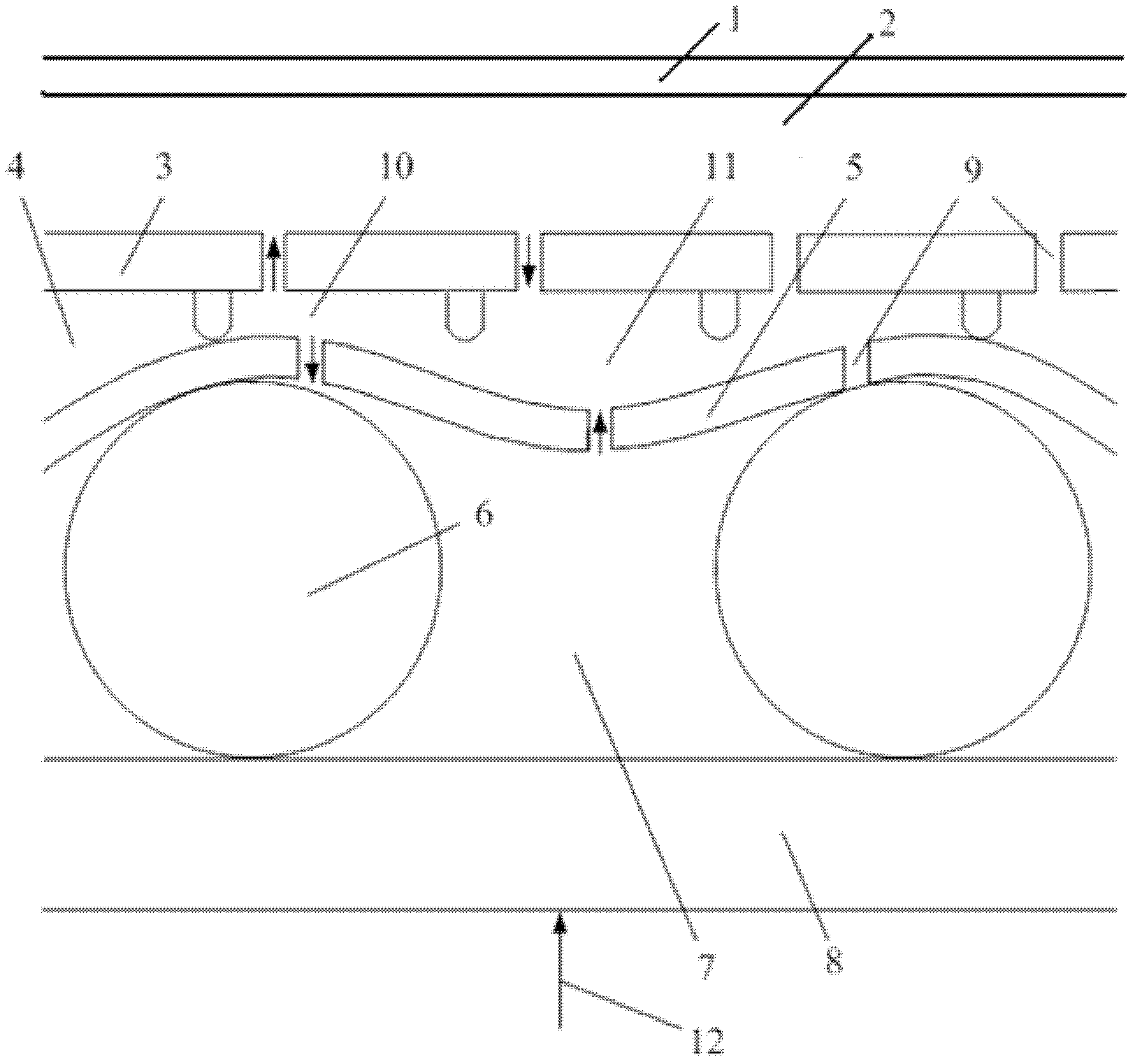

[0026] The present invention is a liquid lubrication system specially used for high-speed bearings, which includes a bearing inner ring 8, a rolling body 6, an elastic layer 5, a bearing outer ring 3, an external oil storage chamber 2, an internal oil storage chamber 4, a communication hole 9 and a bearing Seat 1, the positional connection relationship between them is: the bearing inner ring 8 is located at the inner end of the bearing, the rolling element 6 is arranged between the bearing inner ring 8 and the elastic layer 5, the elastic layer 5 is located outside the rolling element 6, and its inner circular surface In contact with the rolling element 6, the internal oil storage chamber 4 is set between the elastic layer 5 and the bearing outer ring 3, the external oil storage chamber 2 is located outside the bearing outer ring 3, and the communication holes 9 are distributed between the bearing outer ring 3 and the elastic layer 5 Above, the bearing seat 1 is located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com