High-density three-dimensional plant cultivation apparatus

A cultivation device and high-density technology, applied in the field of vertical agriculture, can solve the problems of cost reduction, large operation reserved space, and large nutrient solution consumption, so as to simplify the nutrient solution supply system, increase plant cultivation density, and increase planting density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

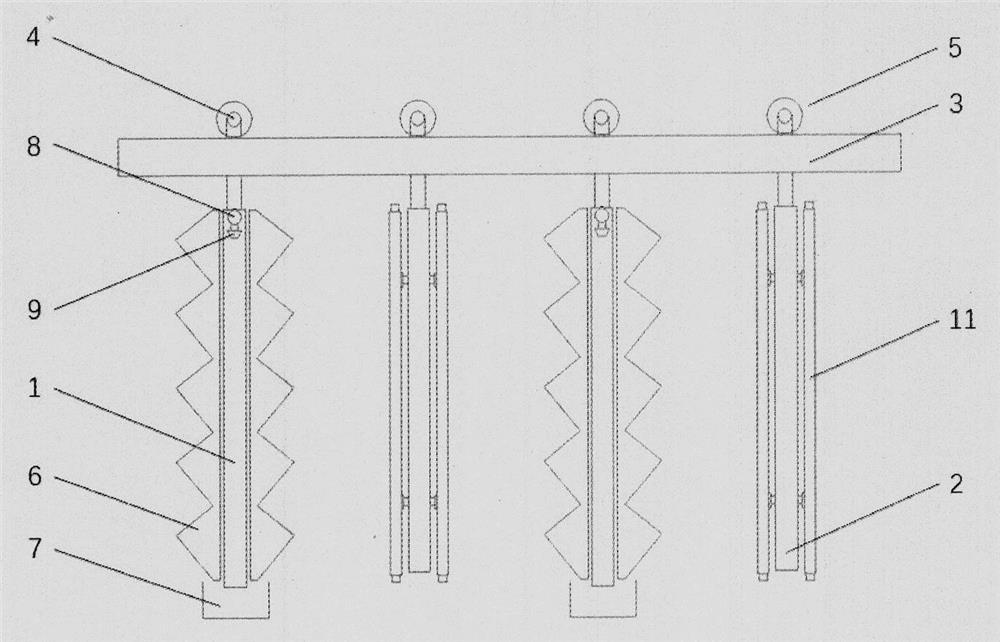

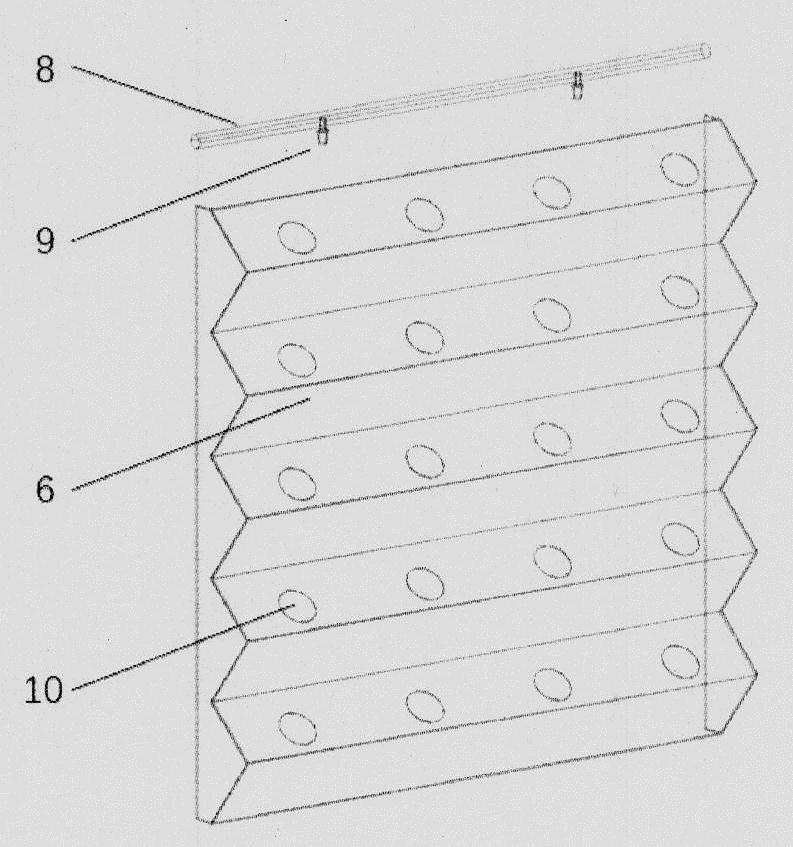

[0020] according to Figure 1-2 As shown, a high-density three-dimensional plant cultivation device of the present invention mainly includes a movable plant frame (1), a movable lamp frame (2), a load-bearing beam (3), and a load-bearing shaft (4). Both the movable plant frame (1) and the movable lamp frame (2) have a load-bearing shaft (4), and the load-bearing shaft (4) can move on the load-bearing beam (3) through rollers (5). Various moving modes such as two-way motor, hand wheel or rocker. The cultivation plate (6) has a stepped design with a plurality of planting holes (10), installed on both sides of the movable plant frame (1), and forms a certain space inside to facilitate the dispersion of the aerosolized nutrient solution. The nutrient solution is transported to the atomizing nozzle (9) for spraying through the delivery pipeline (8) installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com