Warmer

A heater and fixing plate technology, applied in the field of heaters, can solve the problems of slow heating speed, easy damage to electrical components, affecting product life, etc., and achieve the effects of fast heating speed, reducing loss and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

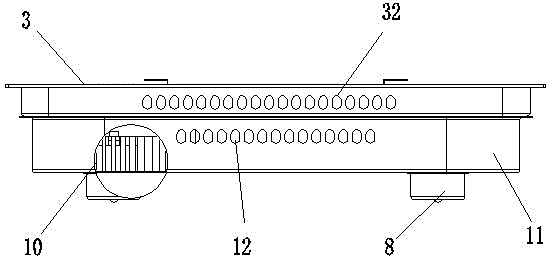

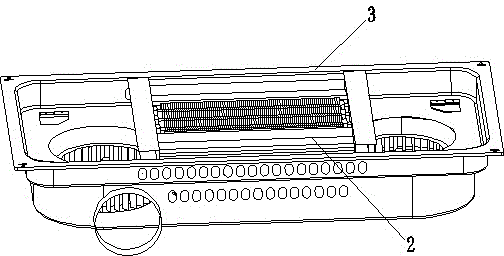

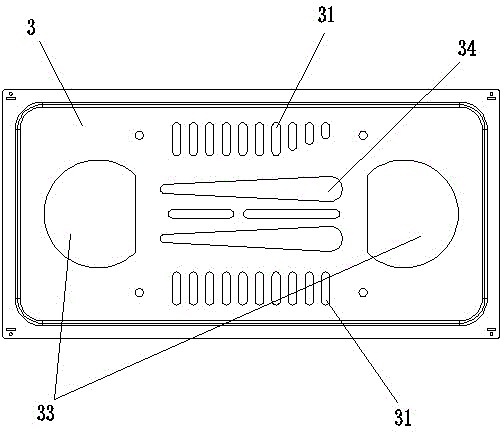

[0019] see Figure 1 to Figure 10 , the embodiment of the present invention is provided with a panel 1, a combined heating module 2, a combined heating module fixing plate 3, a reflector 4, a heating pipe 5, a PTC heating module 6, a heating module fixing frame 7, a fan 8, an air duct partition 9, Air outlet 10, air duct box body 11. The combined heating module 2 includes a reflector 4, a heating tube 5, a PTC heating module 6, and a heating module fixing frame 7. The heating tube 5 and the PTC heating module 6 are fixed on the heating module fixing frame 7, and the heating tube 5 is provided with a reflector 4 , The reflector 4 is fixed on the heating module fixing frame 7, and the reflector 4 is provided with a row of reinforcing ribs 41 for strengthening and cooling. The combined heating module 2 is fixed on the fixed plate 3 of the combined heating module, and the fixed plate 3 of the combined heating module is provided with a heat dissipation hole 31 on the front side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com