Online calibrating device for high-temperature liquid metal flow

A liquid metal and calibration device technology, which is applied in measuring devices, liquid/fluid solid measurement, testing/calibration devices, etc., can solve the problems that liquid metal flowmeters cannot be used to measure high-temperature liquid metals and cannot meet measurement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

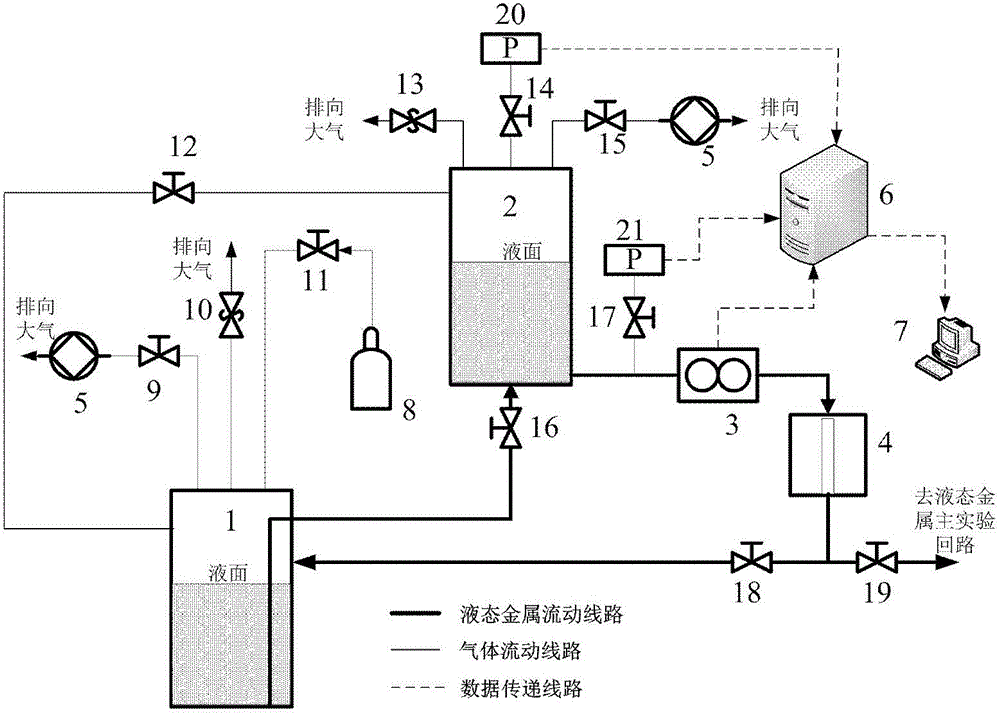

[0027] see figure 1 As shown, the high-temperature liquid metal flow on-line calibration device provided by the present invention mainly includes: a melting tank 1, a liquid storage tank 2, a liquid metal flowmeter 3, an electromagnetic pump 4, a vacuum pump 5, a high-pressure nitrogen cylinder 8, and a pipeline control valve 9 , 11,12,14,15,16,17,18,19, gas safety valve 10,13, first pressure sensor 20, second pressure sensor 21, data collector 6 and computer 7.

[0028] In the high-temperature liquid metal flow rate online calibration device of the present invention, the melting tank 1 is located at the lowest position of the entire calibration device, and its top cover is respectively connected with: a gas safety valve 10, a vacuum pump 5, and a high-pressure nitrogen cylinder 8; the melting tank 1 side A pipeline control valve 12 is externally connected above the liquid surface of the wall to communicate with the gas space above the liquid surface of the liquid storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com