Device for sampling biomembrane on outer surface of pipe growth ring

A sampling device and biofilm technology, applied in the direction of sampling devices, etc., can solve the problems of changing the growth environment and organizational structure of biofilm microorganisms on the outer surface of the pipeline growth ring, inability to sample online, and inconvenient sampling, etc., to achieve convenient and fast installation and antifreeze Reliability, easy sampling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

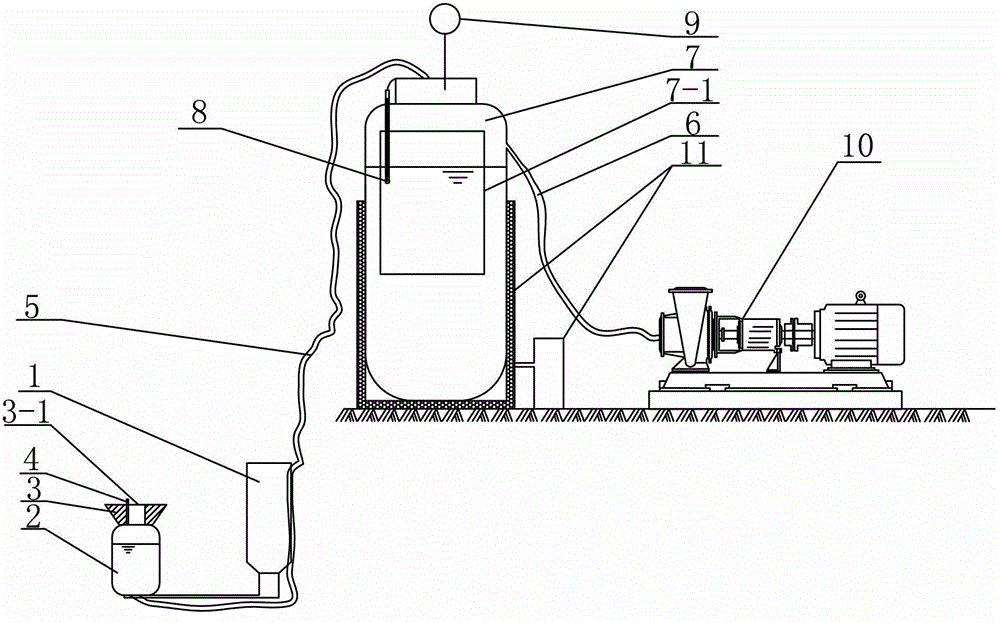

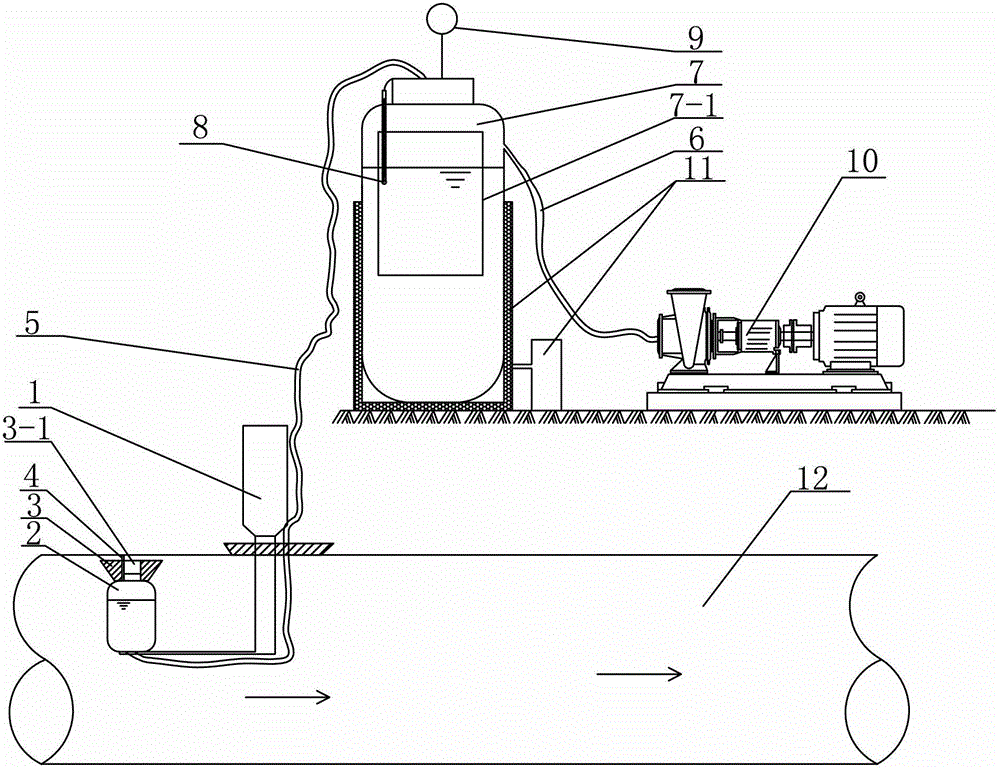

[0008] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, a biofilm sampling device on the outer surface of a pipe growth ring in this embodiment includes an electric push rod 1, a sampling bottle 2, a frustum-shaped rubber stopper 3, a circular scraper 4, a rubber tube 5, a connecting tube 6, a collection Tank 7, thermometer 8, pressure gauge 9, vacuum pump 10, and electric heating element 11; the push rod end of the electric push rod 1 is connected to the bottom of the sampling bottle 2, and the electric push rod 10 is used for sealing connection with the pipeline 12, in the shape of a truncated cone The small-diameter end of the rubber plug 3 is inserted into the mouth of the sampling bottle 2, and the middle of the small-diameter end and the middle of the large-diameter end of the frustum-shaped rubber plug 3 are provided with a coaxial through hole 3-1, which is located in the frustum-shaped rubber plug 3 A circular scraper 4 ...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 This embodiment will be described. The connecting pipe 6 in this embodiment is a rubber connecting pipe. Such setting meets the design requirements and actual needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 Describe this embodiment, the collection tank 7 in this embodiment is a stainless steel collection tank. Such setting meets the design requirements and actual needs. Others are the same as in the first or second embodiment.

[0016] work process

[0017] combine figure 1 and figure 2 To illustrate the working process of the present invention, it is necessary to carry out ultraviolet (wavelength 265mm-266mm) sterilizing treatment on the inside of the sampling bottle and the airtight tank before work. Push the push rods together from the hole into the sampling point under investigation, and ensure that the moving direction of the electric push rod is consistent with the direction of the water flow, so as to prevent the biofilm on the outer surface of the growth ring that has been scraped off from being washed away by the reverse water flow, and ensure the sampling volume. Ensure that the hole between the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com