Rotary piezoelectric generation device

A power generation device and rotary press technology, applied in the field of micro energy, can solve the problems of reducing the service life, reducing the efficiency conversion of the rotating shaft, mechanical energy loss, etc., and achieve the effect of avoiding energy loss, avoiding the structure system, and avoiding the reduction of life span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

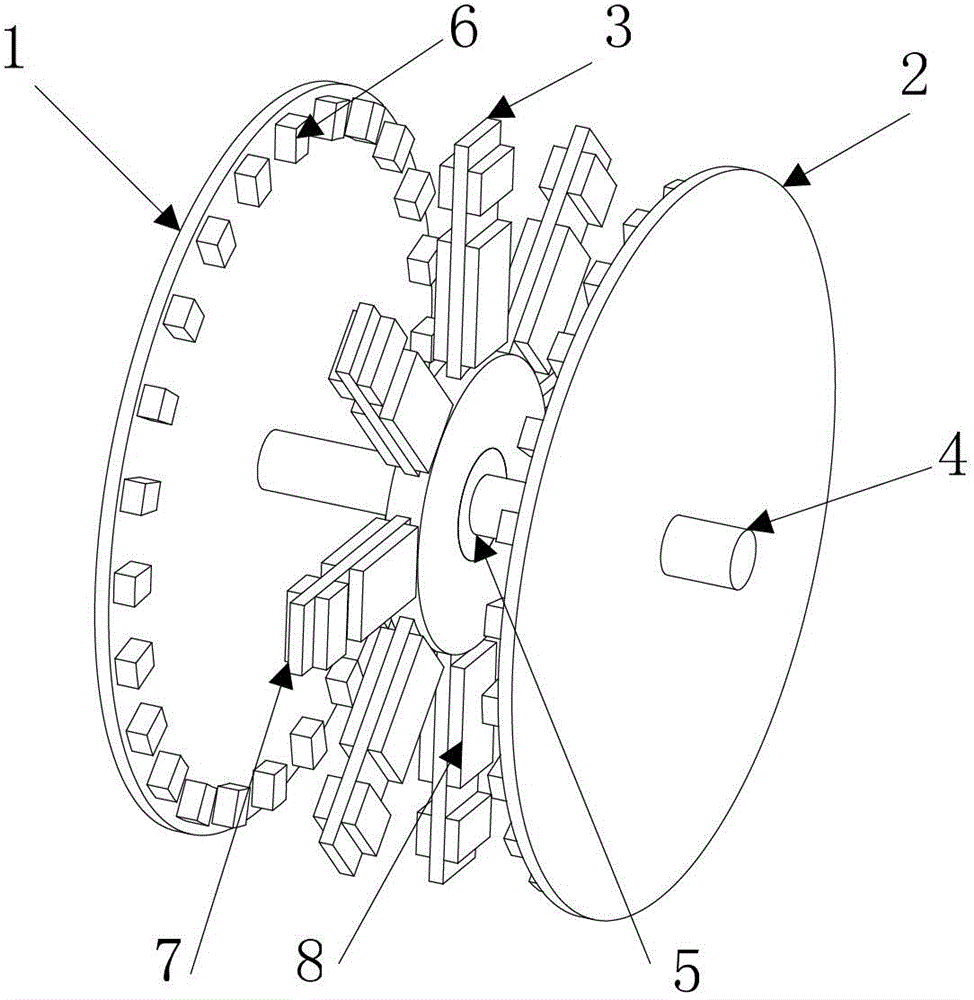

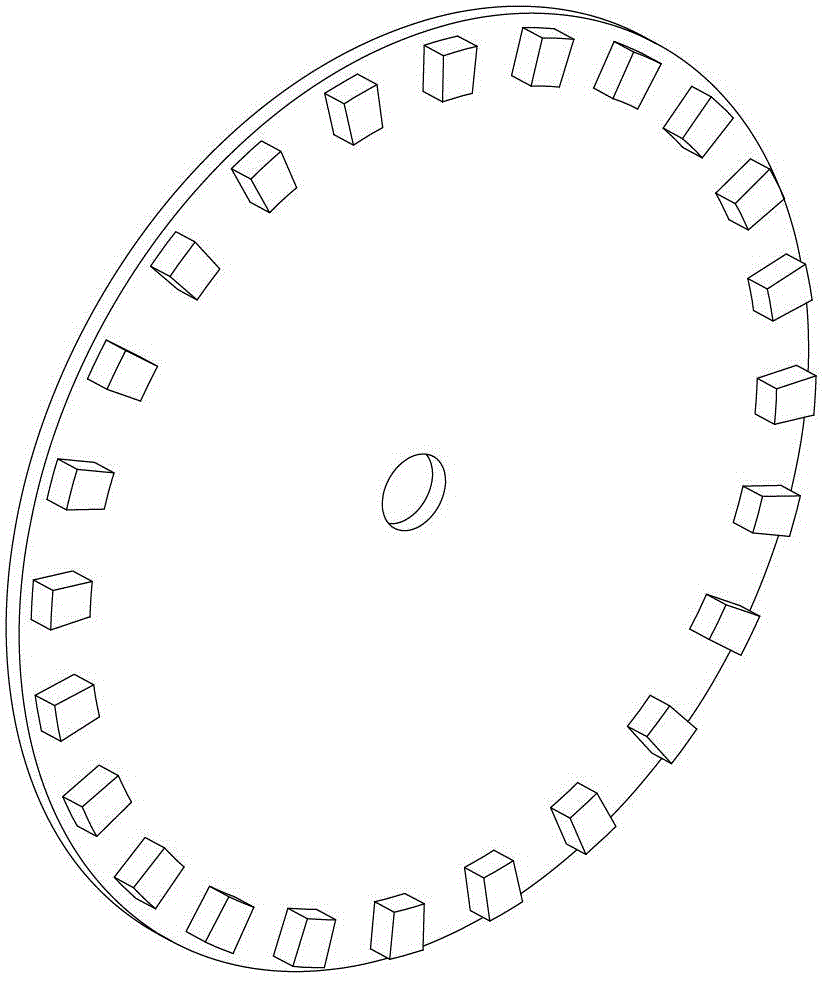

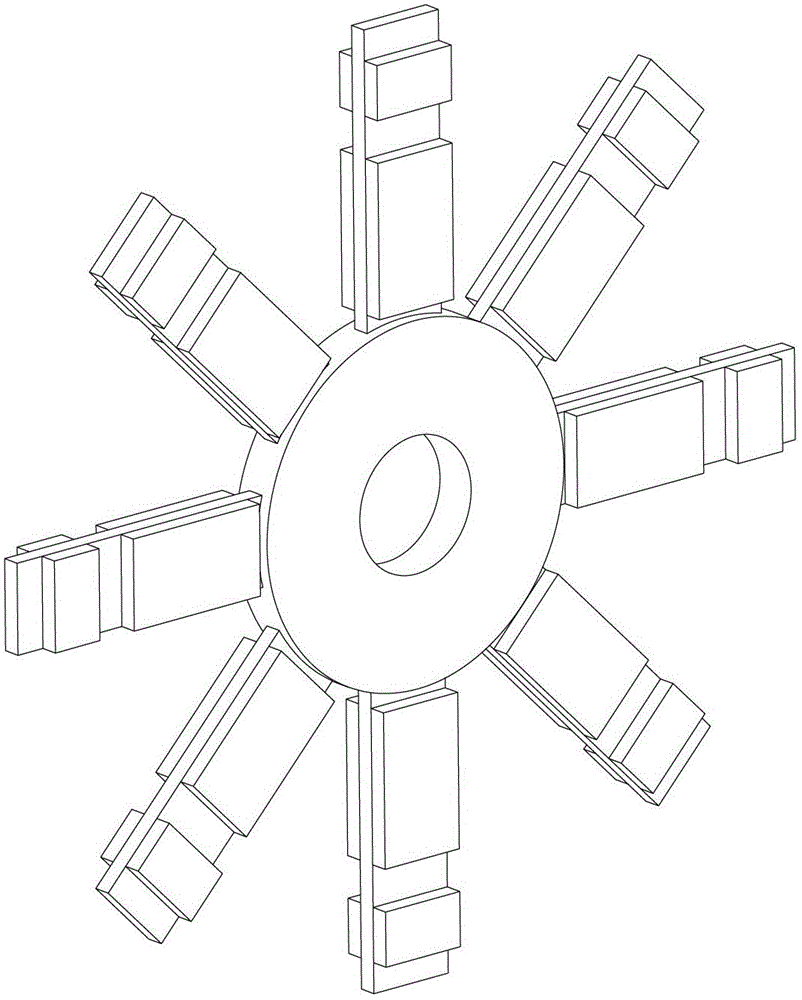

[0021] Such as figure 1 As shown, the rotary piezoelectric power generation device of the present invention includes a rotating shaft and a front excitation wheel, a piezoelectric twin crystal beam array, and a rear excitation wheel respectively installed on the rotation shaft. The front excitation wheel 1 and the rear excitation wheel 2 will be The piezoelectric double crystal beam array 3 is sandwiched in the middle to form a sandwich structure, and there is a certain gap between the three; the front excitation wheel 1 and the rear excitation wheel 2 are both rigidly connected to the rotating shaft 4, and the piezoelectric double crystal beam array 3 passes through the bearing 5 Connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com