Insect larva separation equipment

A technology for separating equipment and larvae, applied in the field of insect breeding, can solve the problems of low separation efficiency, difficult separation, high cost, etc., and achieve the effect of separation and mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

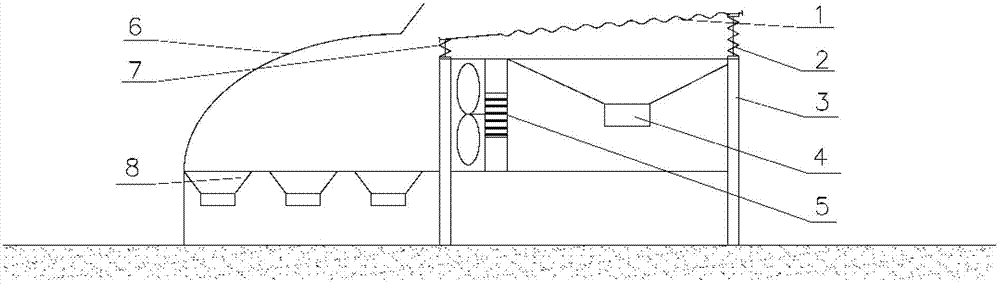

[0016] like figure 1 As shown, the insect larva separation equipment of the present invention includes a separation chamber 6 and a mechanical vibrating device. The mechanical vibrating device includes a wave screen 1 and a support 3. The left end of the wave screen 1 passes through the second spring vibrator 7, and the right end passes through the second spring vibrator. A spring vibrator 2 is connected with the support 3 respectively, the first spring vibrator 2 is higher than the second spring vibrator 7, so that the right end of the wave sieve 1 is high and the left end is low, and a separation funnel 4 is provided below the wave sieve 1 for use To collect the sieved medium, a separation fan 5 is provided on the left side of the separation funnel 4, and the separation chamber 6 is located at the bottom left of the wave screen 1. The separation chamber 6 can avoid the escape of the material during the wind separation process. The bottom of the separation chamber 6 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com