Plant extract dripping pill

A plant extract and extract technology, applied in the field of medicine, can solve the problems of low bioavailability, slow onset, inconvenient taking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

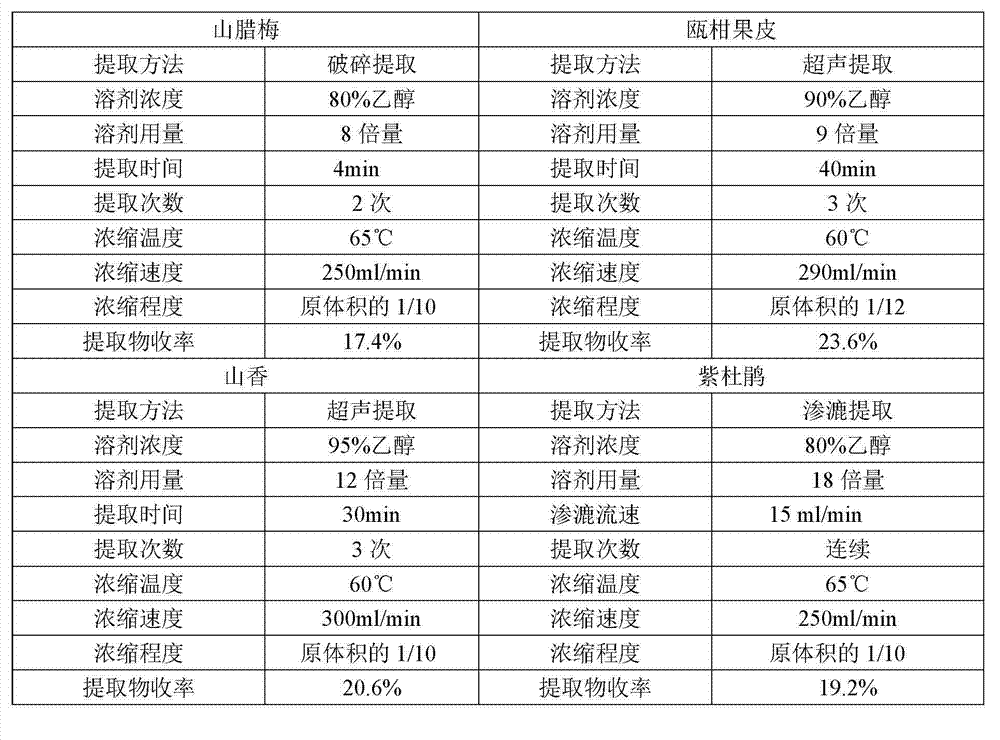

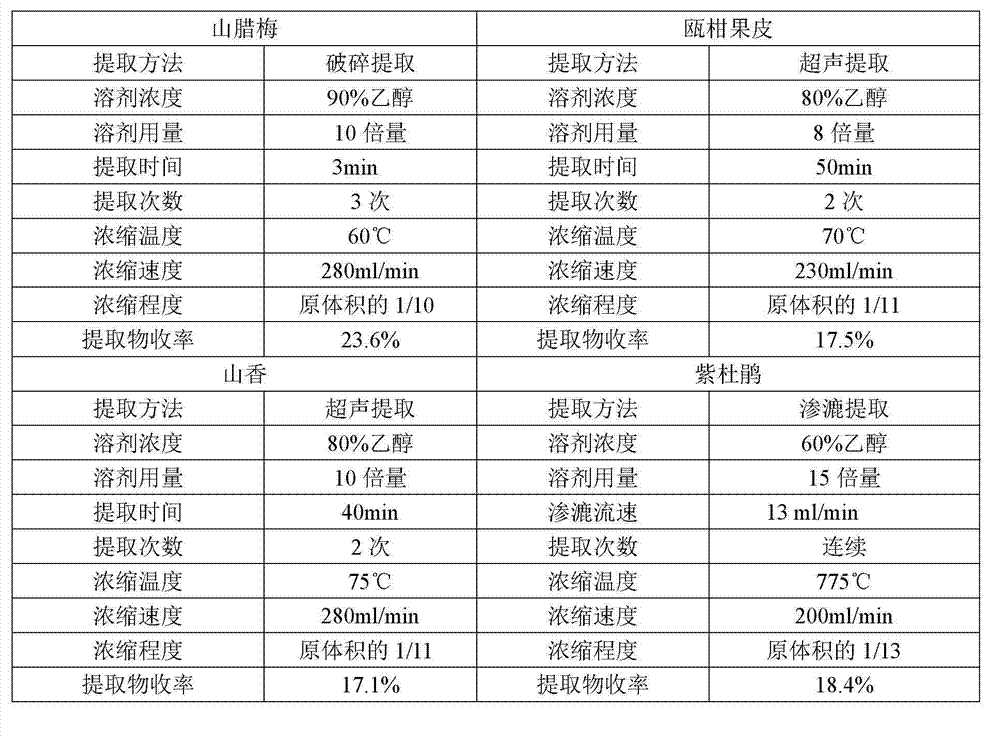

Image

Examples

Embodiment 1

[0025]The dripping pill is made by mixing polyethylene glycol 4000 and polyethylene glycol 6000 according to the weight ratio of 1:1 and then heating and melting to obtain the mixed base; Add the plant extract to the mixed matrix and stir evenly at ℃ to obtain a melt, keep it warm at 75-80°C for 20-30 minutes, drain the air bubbles in the melt, and set aside; adjust the temperature control system of the dropping pill machine, Keep the temperature of the dripper at 75-80°C, keep the temperature of the condensate simethicone at 8-12°C, put the above molten liquid in the liquid storage tank of the dropping pill machine at a drop distance of 5-6 cm, drop speed Drop into the condensate under the condition of 40-60 drops / minute, condense into pellets, the weight of the pellets is 35-40 mg, take out the formed dropping pills from the outlet of the dropping pill machine, filter off the condensing agent on the surface, and get it;

[0026] The plant extract in the dropping pill is comp...

Embodiment 2

[0028] The dripping pill is made by mixing polyethylene glycol 4000 and polyethylene glycol 6000 according to the weight ratio of 1:3 and then heating and melting to obtain the mixed base; Add the plant extract to the mixed matrix and stir evenly at ℃ to obtain a melt, keep it warm at 75-80°C for 20-30 minutes, drain the air bubbles in the melt, and set aside; adjust the temperature control system of the dropping pill machine, Keep the temperature of the dripper at 75-80°C, keep the temperature of the condensate simethicone at 8-12°C, put the above molten liquid in the liquid storage tank of the dropping pill machine at a drop distance of 5-6 cm, drop speed Drop into the condensate under the condition of 40-60 drops / minute, condense into pellets, the weight of the pellets is 35-40 mg, take out the formed dropping pills from the outlet of the dropping pill machine, filter off the condensing agent on the surface, and get it;

[0029] The plant extracts in the dropping pills are ...

Embodiment 3

[0031] The dripping pill is made by mixing polyethylene glycol 4000 and polyethylene glycol 6000 according to the weight ratio of 1:5 and then heating and melting to obtain the mixed base; Add the plant extract to the mixed matrix and stir evenly at ℃ to obtain a melt, keep it warm at 75-80°C for 20-30 minutes, drain the air bubbles in the melt, and set aside; adjust the temperature control system of the dropping pill machine, Keep the temperature of the dripper at 75-80°C, keep the temperature of the condensate simethicone at 8-12°C, put the above molten liquid in the liquid storage tank of the dropping pill machine at a drop distance of 5-6 cm, drop speed Drop into the condensate under the condition of 40-60 drops / minute, condense into pellets, the weight of the pellets is 35-40 mg, take out the formed dropping pills from the outlet of the dropping pill machine, filter off the condensing agent on the surface, and get it;

[0032] The plant extract in the dropping pill is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com