Static pressure workbench for forming gear grinding machine

A workbench and gear grinding machine technology, applied in the direction of gear cutting machines, gear teeth, mechanical equipment, etc., can solve the problems of reducing rotational friction, easy wear of contact surfaces, and inability to adjust the working platform, so as to achieve reduced friction and high rotation accuracy , Improve the effect of radial adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

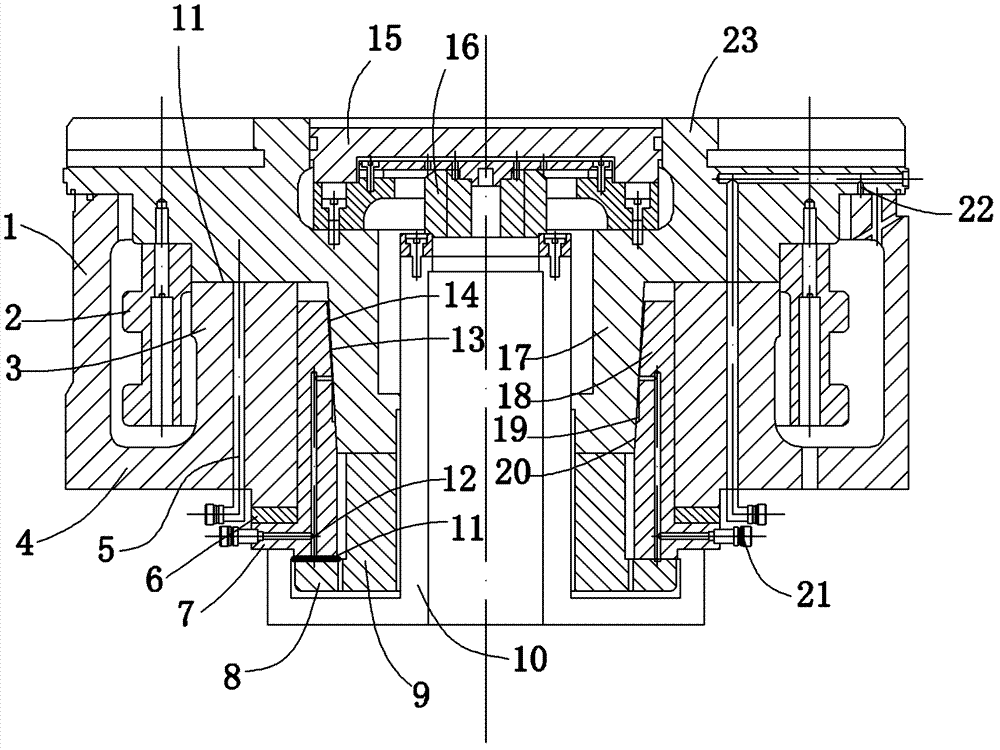

[0021] Example: A static pressure table of a gear grinding machine (see attached figure 1 ), including the housing 4, the housing is a U-shaped rotating body that rotates around an axis parallel to the U-shaped side, the U-shaped wall inside the housing is the inner support 3, and the U-shaped wall outside is the outer support 1. The height of the inner support part is smaller than the outer support part. A working platform 23 is fixed on the upper surface of the housing, a tapered column 17 is arranged in the middle of the working platform, and the middle of the tapered column is a circular hole. A tapered sleeve 18 is provided between the tapered column and the inner side wall of the inner support portion. One end of the tapered sleeve is a tapered hole 14 matching the outer wall of the tapered column, and the other end of the tapered sleeve is provided with a vertical eversion flange. 7. The reverse flanging hooks the bottom surface of the shell. An adjustment pad 6 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com