Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc. It can solve problems such as difficulty in balancing, increased resonance vibration, and deteriorated noise performance, and achieves maximum traction performance , Increase the shear force and improve the performance of the mud road

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

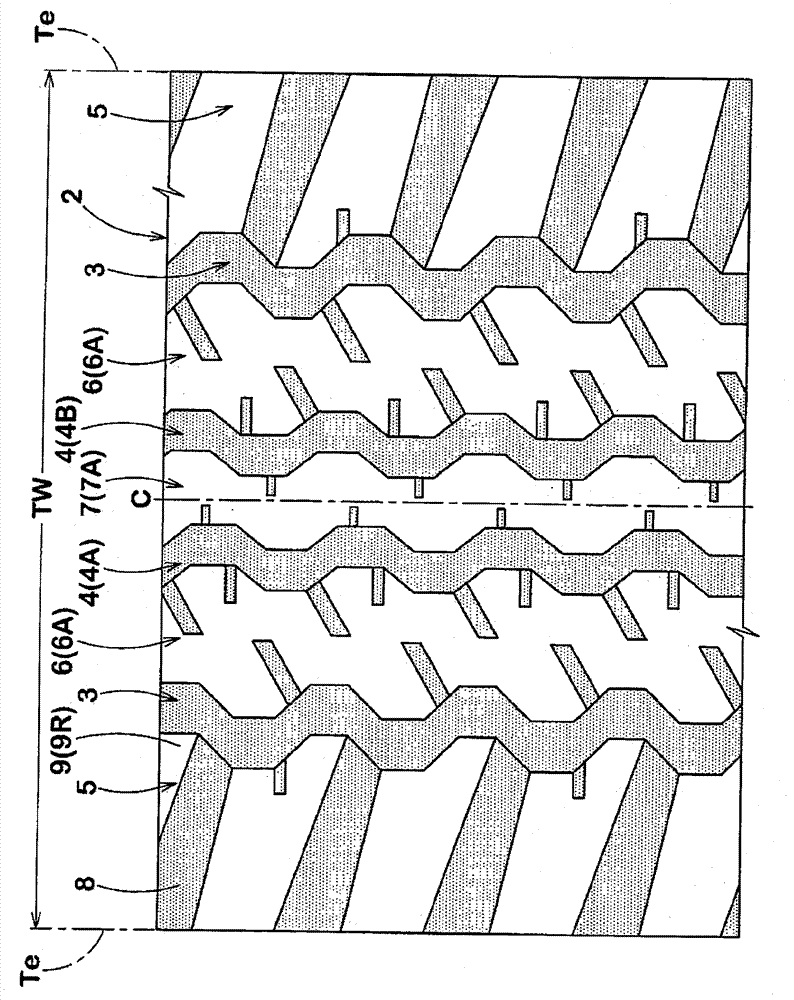

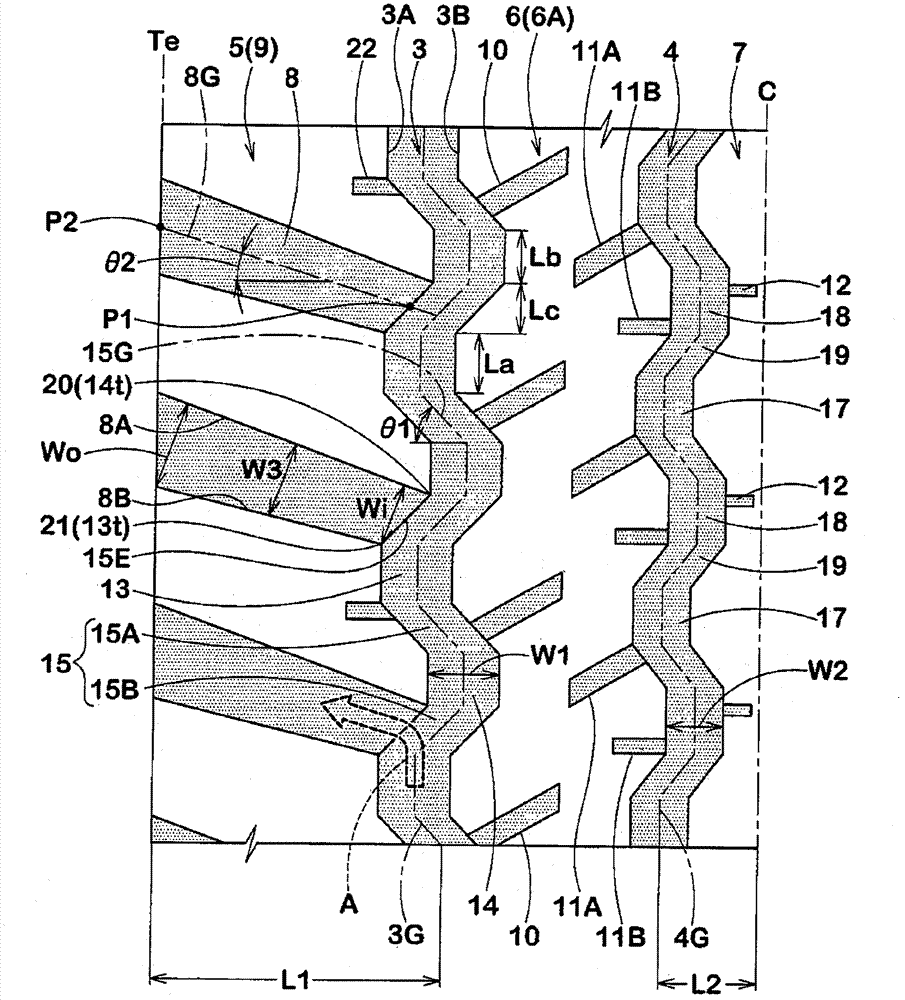

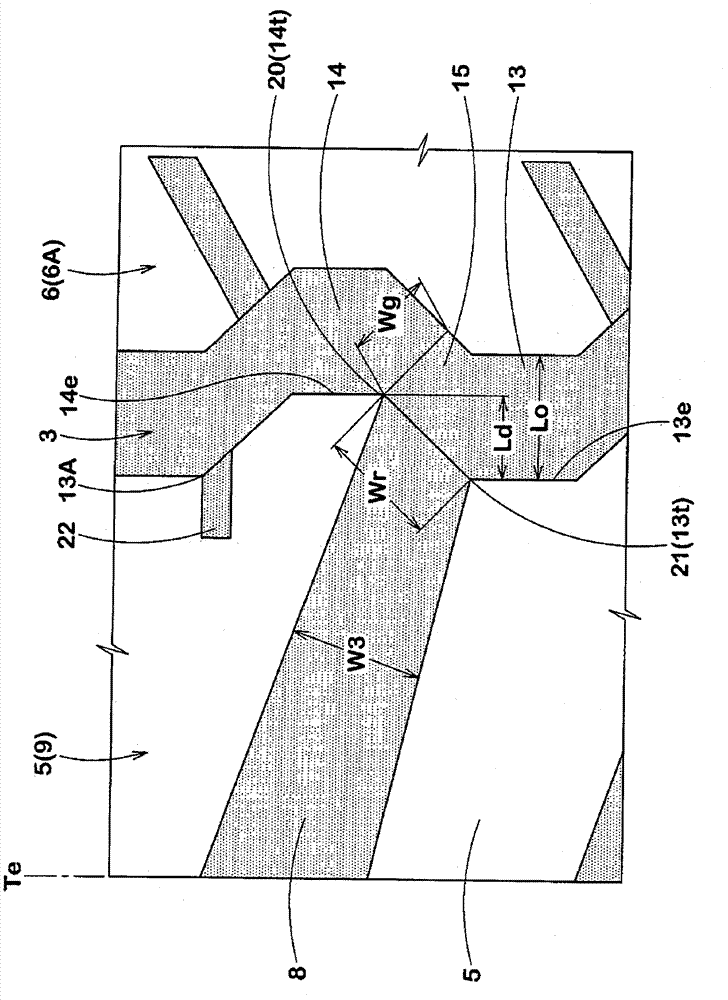

[0053] Manufacturing has figure 1 The tread pattern and the pneumatic tires (size: 285 / 60R18) based on the specifications in Table 1 were tested for their various properties. Among them, the common specifications are as follows.

[0054] Ground width TW: 200mm

[0055]

[0056] Groove width W1 / ground width TW: 3.1%

[0057] Groove depth D1: 10.0mm

[0058] The angle θ1 of the transition part relative to the tire axial direction: 45 degrees

[0059] Ratio La / Lb of the tire circumferential lengths of the inner groove portion and the outer groove portion: 1.17

[0060]

[0061] Groove width W2 / ground width TW: 4.1%

[0062] Groove depth D2: 10.0mm

[0063] The angle of the central transition part relative to the tire axis: 40 degrees

[0064]

[0065] Groove depth D3 / D1: 90%

[0066]

[0067] Groove depth 5.0~8.0mm

[0068]

[0069] Groove depth 3.0~5.0mm

[0070] The test method is as follows.

[0071]

[0072] Install the test tires on all the wheels of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com