Contact backstop of logarithmic spiral profile wedge blocks

A technology of logarithmic spiral and backstop, which is applied in the field of contact backstop, which can solve the problems affecting the stability, reliability and service life of work performance, automatic recovery, uneven wear, etc., and achieves small stress fluctuations, Good backstop effect and small contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below with embodiments in conjunction with the accompanying drawings.

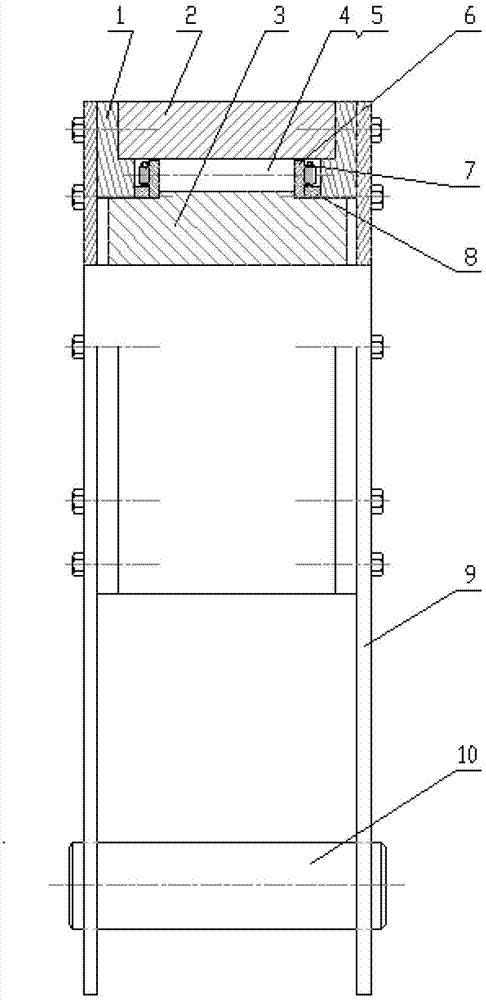

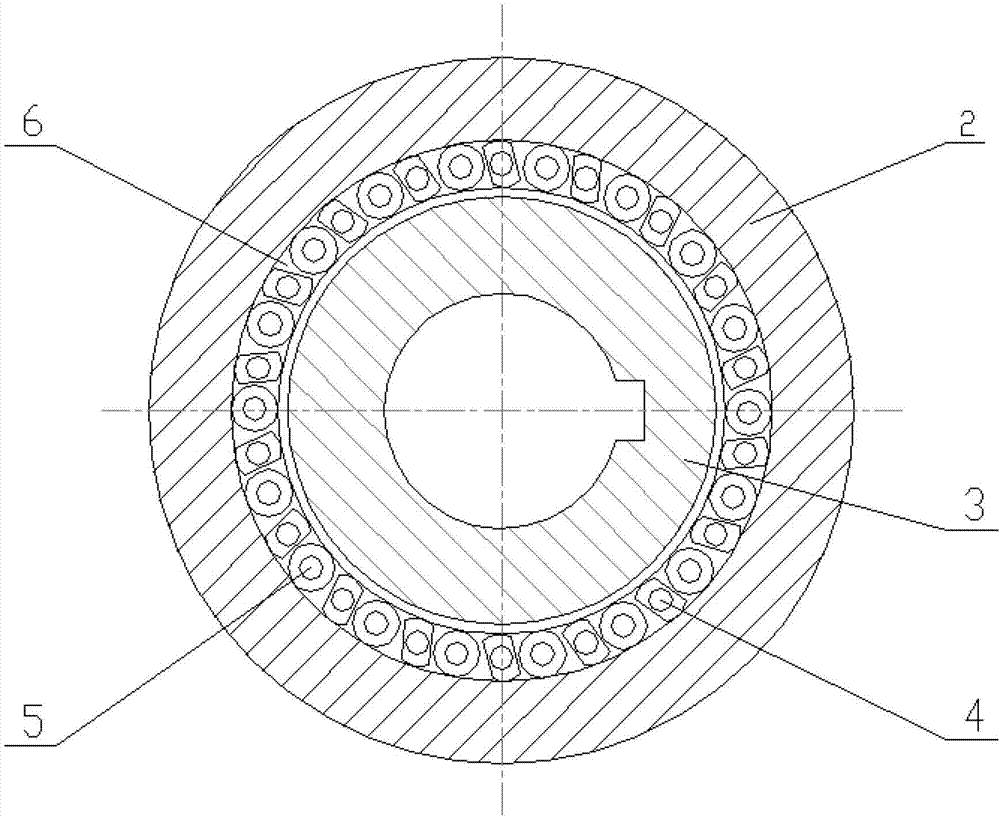

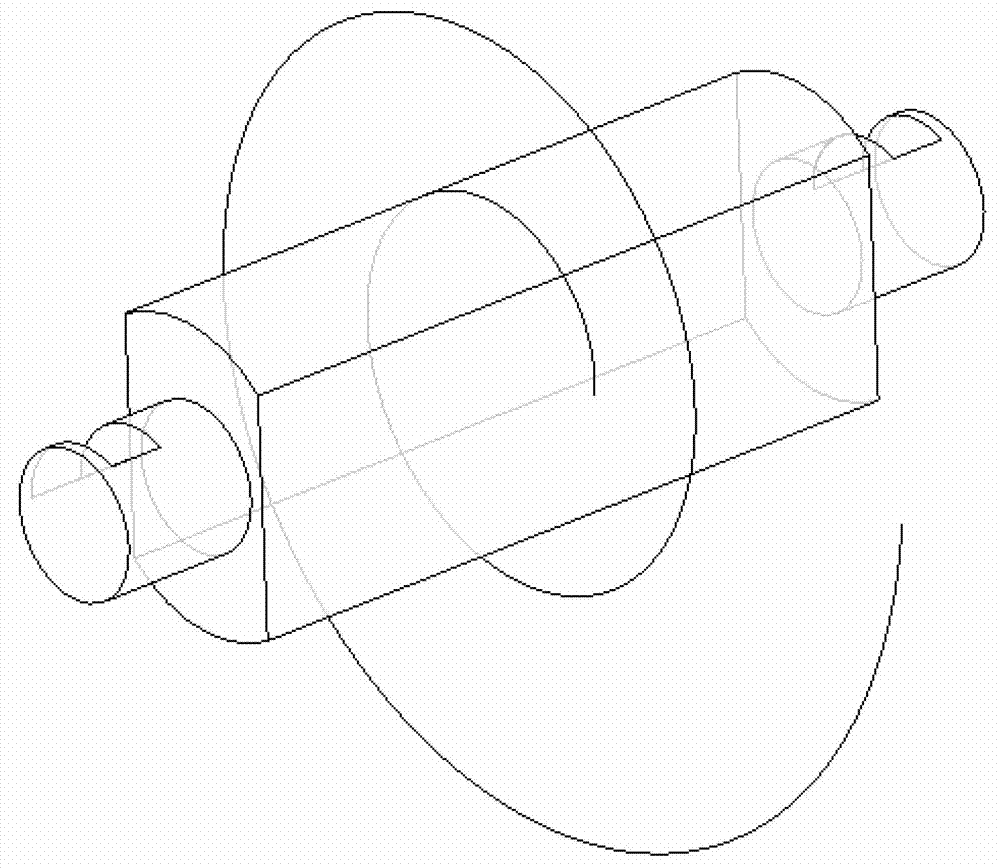

[0016] Such as figure 1 , 2 , 3, and 4, a contact backstop for a logarithmic helical profile wedge, consisting of an end cover 1, an outer ring 2, an inner ring 3, a logarithmic helical profile wedge 4, and a support roller Column 5, cage 6, return spring 7, retaining ring 8, backstop arm 9 and anti-rotation pin 10 constitute. Among them, there are two end caps 1, two backstop arms 9, and the two backstop arms 9 are connected with an anti-rotation pin 10, and the end cap 1 and the backstop arm 9 are fixed to the outer ring 2 with screws; the outer ring 2 passes through The backstop arm 9 and the anti-rotation pin 10 are fixed with the locating piece, so as to realize the overall positioning of the backstop; 8~50 wedges 4 and 4~30 supporting rollers 5 are evenly arranged between the outer ring 2 and the inner ring 3 , the wedges 4 and suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com