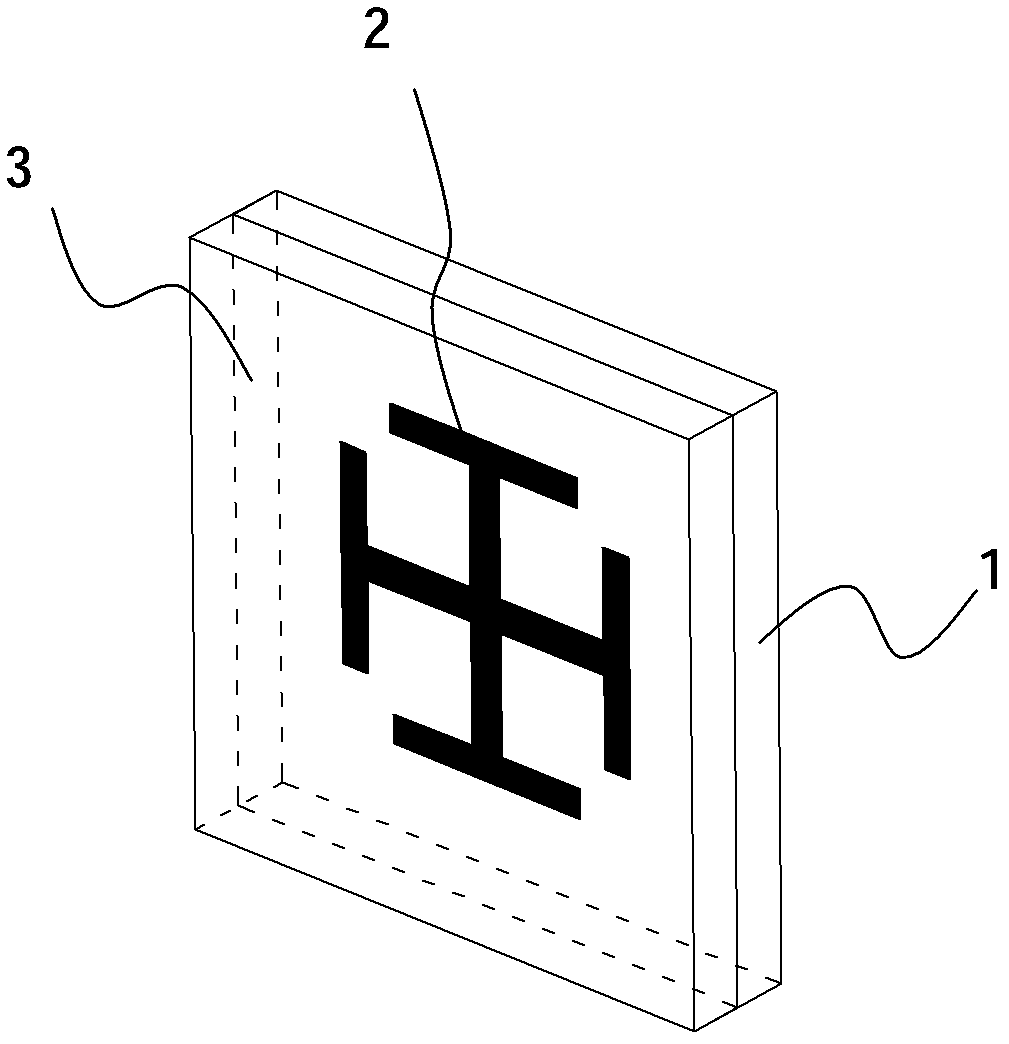

Method for manufacturing metamaterial panel, metamaterial antenna cover and manufacturing method of metamaterial antenna cover

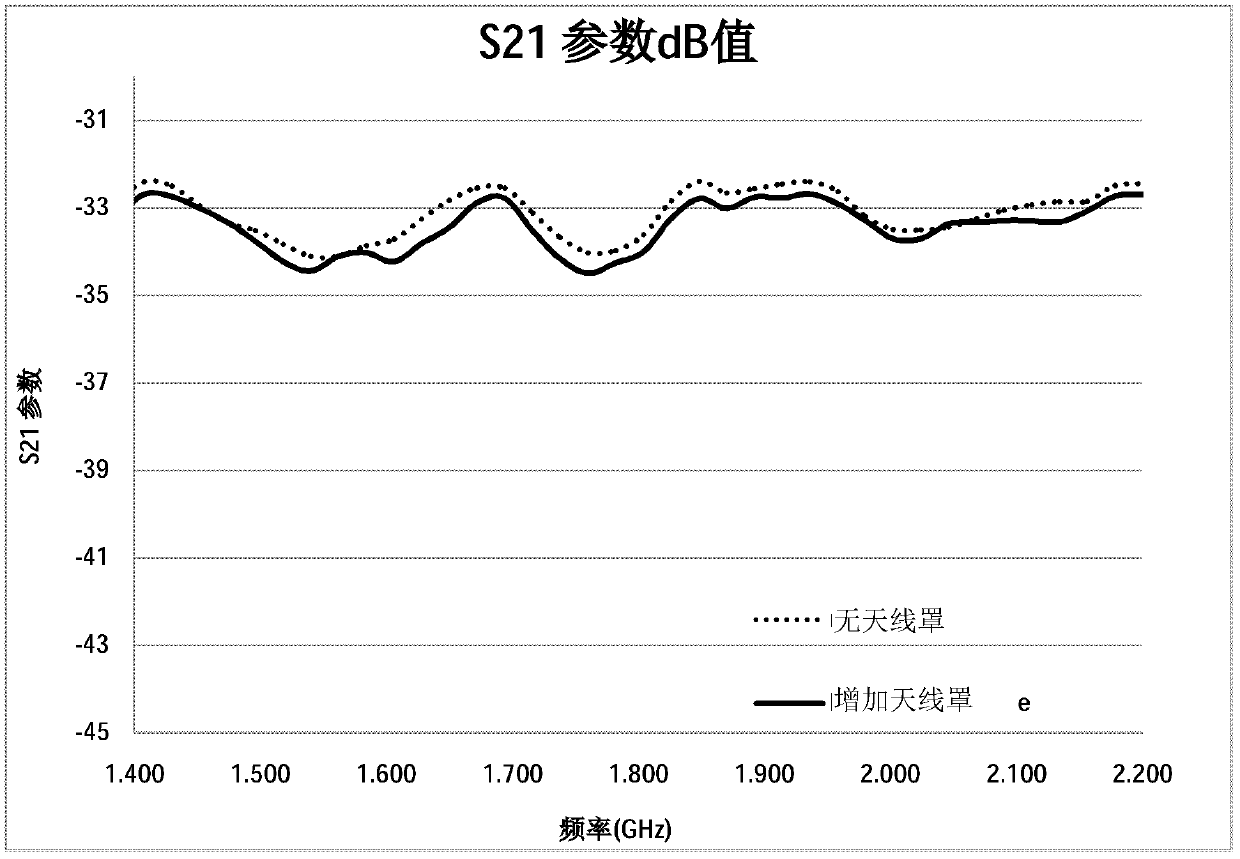

A manufacturing method and metamaterial technology, applied in the field of metamaterials, can solve problems such as poor wave transmission performance, antenna clutter influence, electromagnetic wave transmission, etc., and achieve beautification of appearance, stable working performance, dielectric constant and loss tangent low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

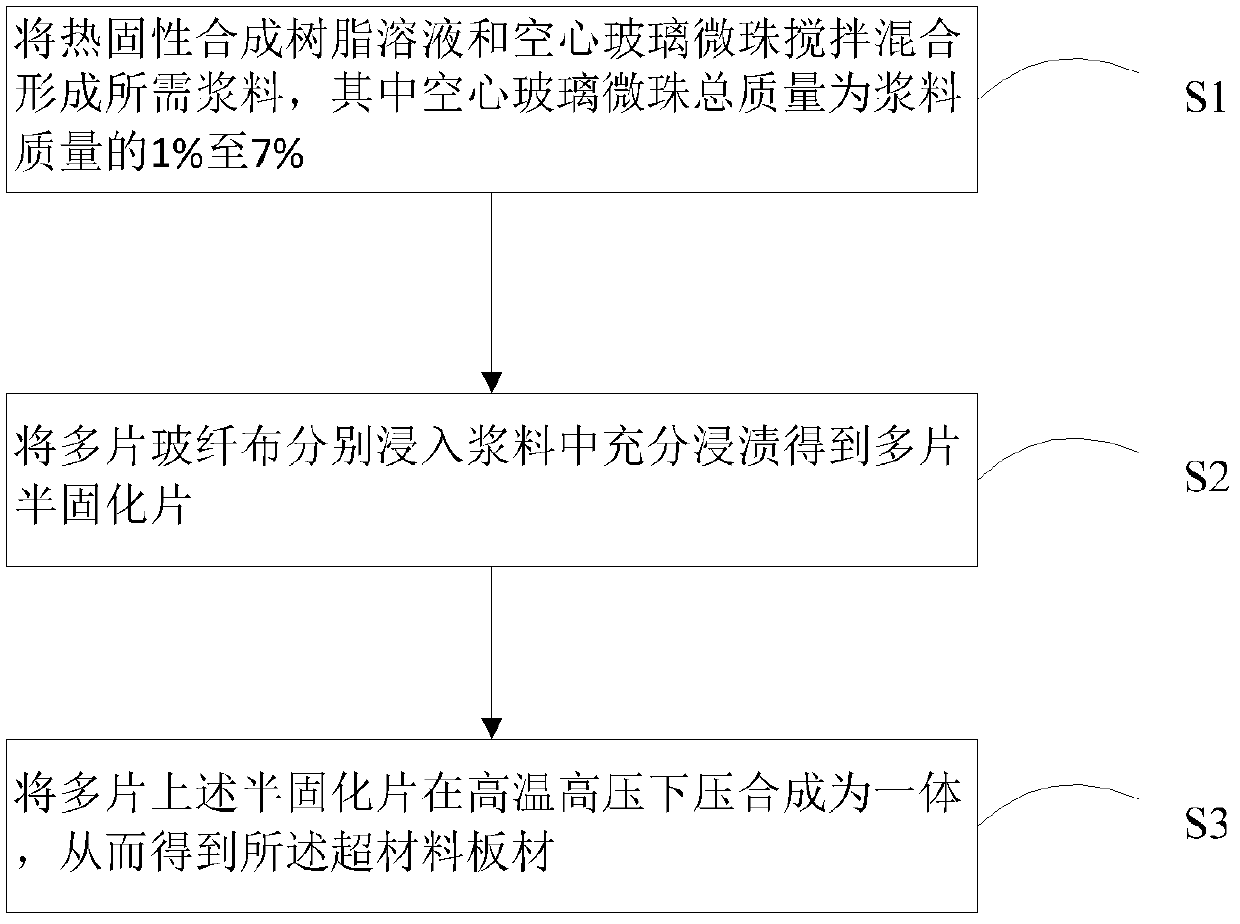

Method used

Image

Examples

Embodiment Construction

[0036] Light, as a kind of electromagnetic wave, when it passes through glass, because the wavelength of light is much larger than the size of atoms, we can use the overall parameters of the glass, such as the refractive index, rather than the detailed parameters of the atoms that make up the glass to describe The response of glass to light. Correspondingly, when studying the response of materials to other electromagnetic waves, the response of any structure in the material whose scale is much smaller than the wavelength of the electromagnetic wave to electromagnetic waves can also be described by the overall parameters of the material, such as the dielectric constant ε and magnetic permeability μ. By designing the structure of each point of the material, the dielectric constant and magnetic permeability of each point of the material are the same or different, so that the overall dielectric constant and magnetic permeability of the material are arranged in a certain order, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com