Hybrid hydraulic steel plate coiling mechanism

A hydraulic and steel plate technology, which is applied in the field of steel plate curling mechanism, can solve the problems of inconsistent diameters of forming pipes, increased equipment vibration, and influence on engineering use, and achieve the effects of reducing human influence factors, improving control accuracy, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

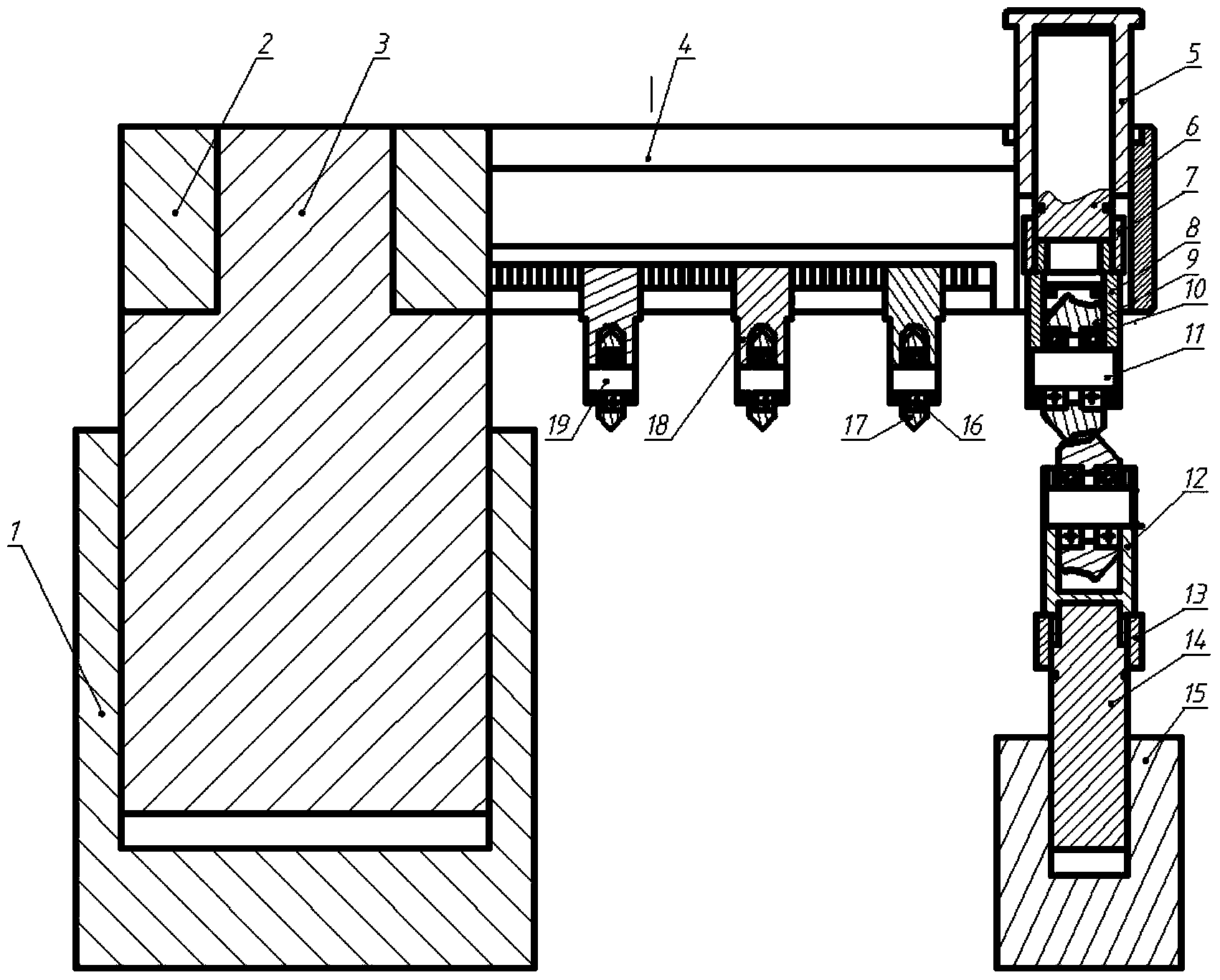

[0029] According to the attached Figure 1~1 2. Introduce in detail the hybrid hydraulic type steel plate curling mechanism of the present invention.

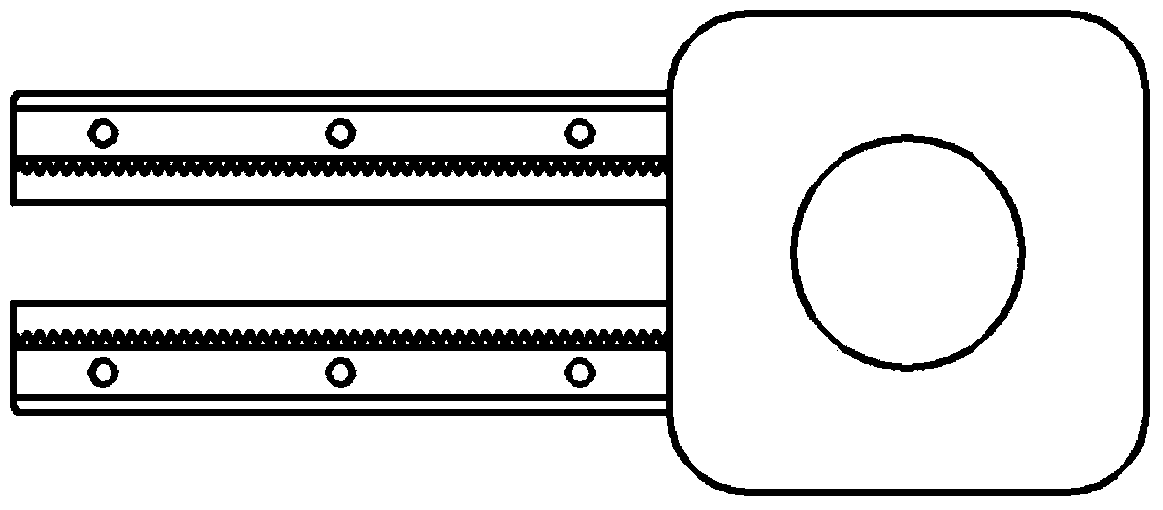

[0030] The upper support 3 is installed on the bottom support I1, and the upper support 3 can move up and down along the bottom support I1 through the power provided by the hydraulic system to realize the position adjustment of the whole mechanism in the vertical direction; the cantilever support 2 is set outside the upper support 3, When the upper bracket 3 rises to a certain height along the bottom support I1, the cantilever frame 2 can realize the rotation of the maximum 90° angle along the upper bracket 3, and the cantilever frame 2 can be rotated when the parts on the cantilever frame 2 need to be replaced. The cantilever frame 2 rotates to a larger angle relative to the space, which is convenient for quick replacement of parts; on the upper layer of the cantilever frame 2 is a cantilever cover 4. When the pressure roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com