Composite sulfide solid lubricating film and preparation method thereof

A solid lubricating and sulfide technology, applied in the field of composite sulfide solid lubricating film layers and their preparation, can solve the problems of unsatisfactory lubricating properties of solid lubricating coatings, and achieve compact structure, promotion of adsorption and diffusion, and many crystal defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

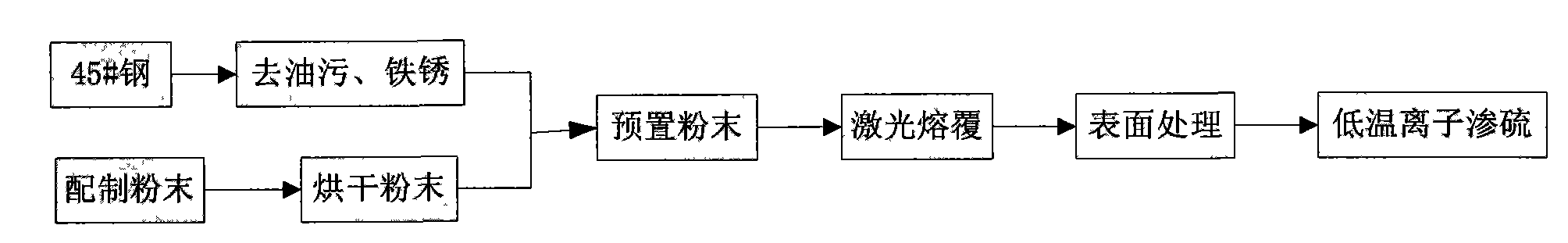

[0028] The implementation process steps of the present invention are as follows:

[0029] 1. Self-made Ni-based cermet powder rich in Fe, W, and Mo. After drying, pre-set 1.5mm-2.5mm thick powder on the surface of No. 45 steel substrate, and then perform laser cladding treatment. The specific process parameters are: 5kW cross flow CO 2 Laser processing system, the power is 3400W~3600W, and the scanning speed is 180mm / min~200mm / min.

[0030] 2. Carry out surface treatment on the laser cladding layer, including fine grinding, mechanical polishing and ultrasonic cleaning, and cover and shield the non-sulfurizing surface.

[0031] 3. Perform low-temperature ion sulfurization treatment on the laser cladding layer. It is to connect the substrate after laser cladding to the cathode, and the furnace wall to the anode. When the vacuum reaches 1Trro, apply high-voltage direct current between the anode and the cathode. The sulfurizing temperature is 170°C-220°C, and the sulfur-containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com