Method for concrete pipe segment lining structure capable of adapting to surrounding rock deformation

A surrounding rock deformation and concrete technology, which is applied in shaft lining, tunnel lining, earthwork drilling and mining, etc., can solve the problems of small formation deformation, segment lining structure damage, and limited space for surrounding rock deformation, so as to suppress the deformation of surrounding rock Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0024] A method for making the concrete segment lining structure adaptable to the deformation of the surrounding rock, the steps of which are as follows:

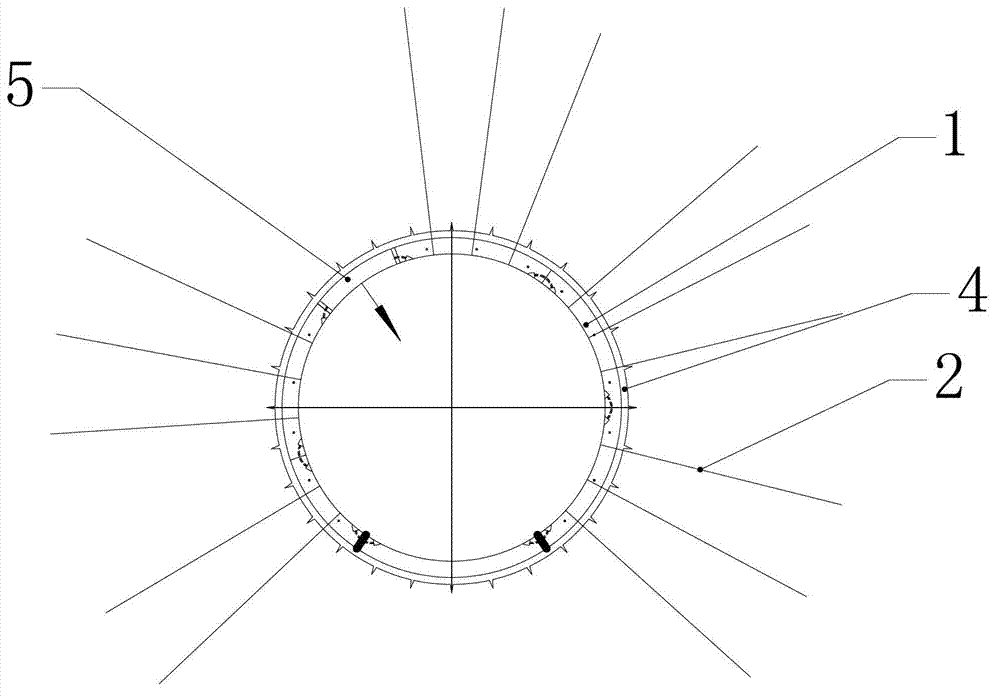

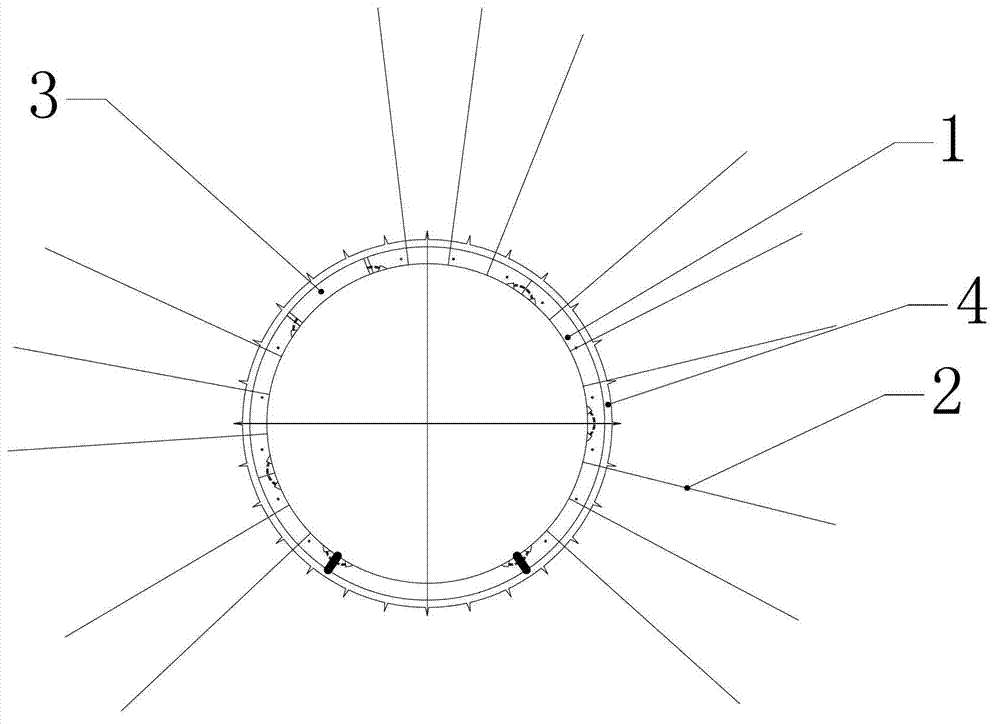

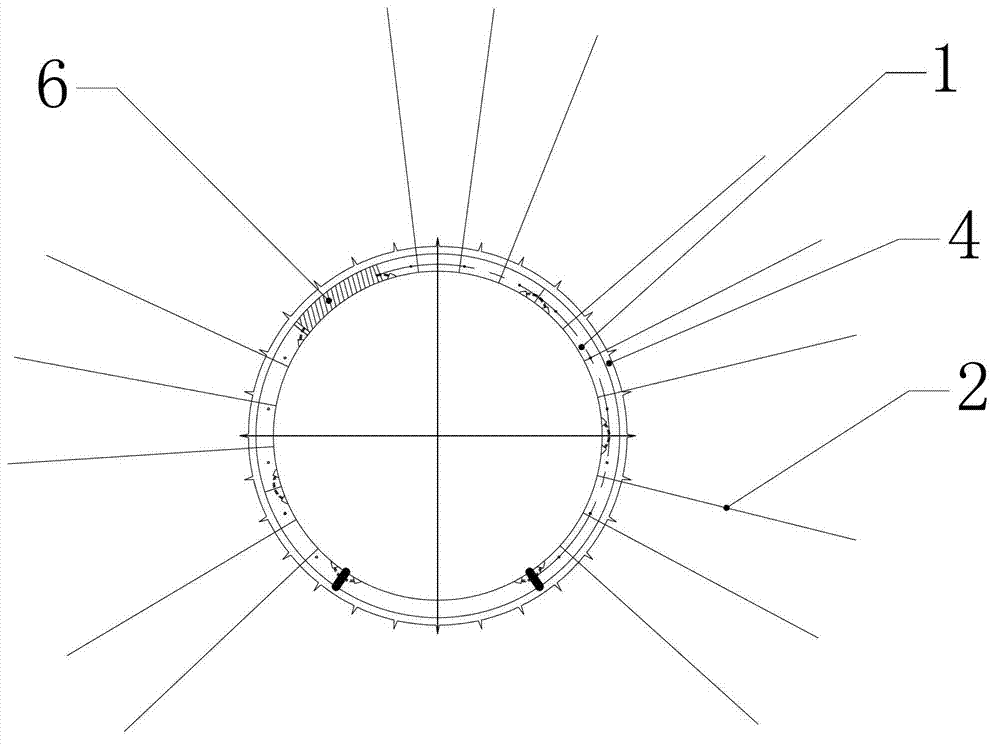

[0025] 1), such as figure 1 As shown, after the tunnel excavation, the segment lining is assembled to form a ring-closed lining structure 1, and then the anchor rod 2 is drilled radially around the surrounding rock through the segment, and the radial anchor rod 2 penetrates Pass through the segment lining 1 and be fastened by the surrounding rock; then fill the gap 4 behind the segment wall with grouting and wait for solidification. After the filler in the gap 4 behind the segment wall is solidified, remove a segment 5 in the lining structure 1, so that the closed segment lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com