Liquid gas fuel liquid direct-injection device and composite valve of engine

A technology of liquefied gas fuel and engine, applied in the direction of combustion engine, internal combustion piston engine, engine components, etc., to achieve the effects of suppressing surface ignition and deflagration, good inheritance, and improving charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

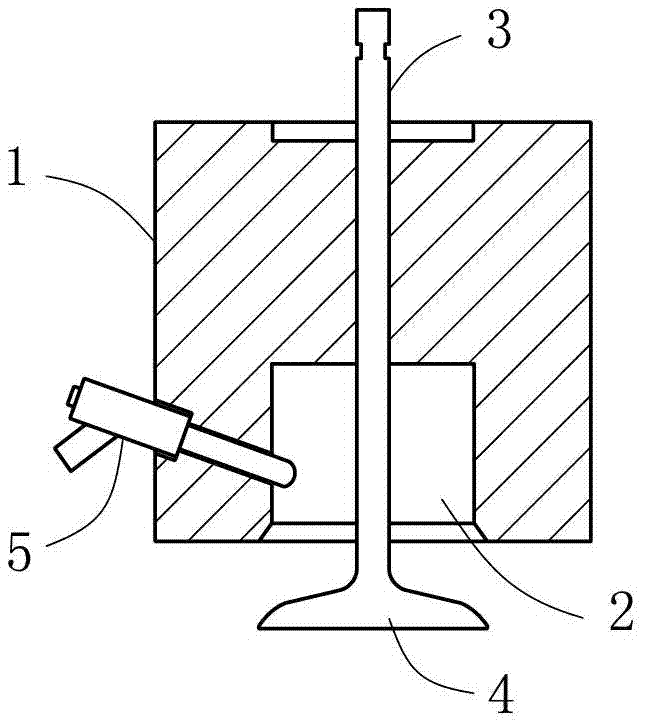

[0019] Such as figure 1 As shown, a liquefied gas fuel liquid direct injection device includes a cylinder head 1 installed on the engine casing, the cylinder head 1 has an isolation chamber 2 with one end open, and the isolation chamber 2 communicates with the combustion chamber of the engine through the open end , the cylinder head 1 is slidably installed with a bacterium valve rod 3 driven by a power unit, usually the power unit is a cam group of an engine gas distribution system or an electric mode, etc., those skilled in the art can use conventional technical means to implement, and will not repeat them here. The end of the bacteria valve rod 3 has a bacteria valve 4 used to seal the open end of the isolation chamber 2; the cylinder head 1 is equipped with an electronically controlled liquid spray valve 5 for measuring the injection amount and injection timing, and the electronically controlled liquid spray valve The shower head of 5 stretches into isolation cavity 2.

[...

Embodiment 2

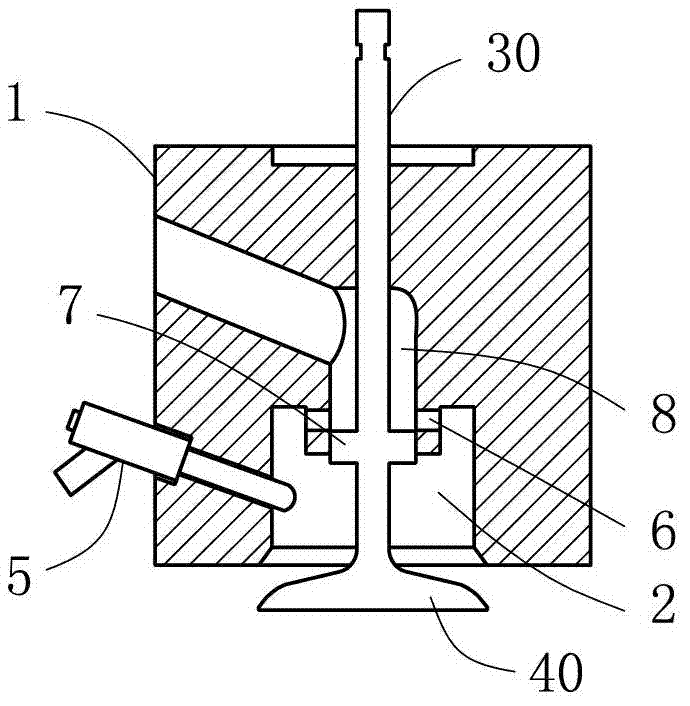

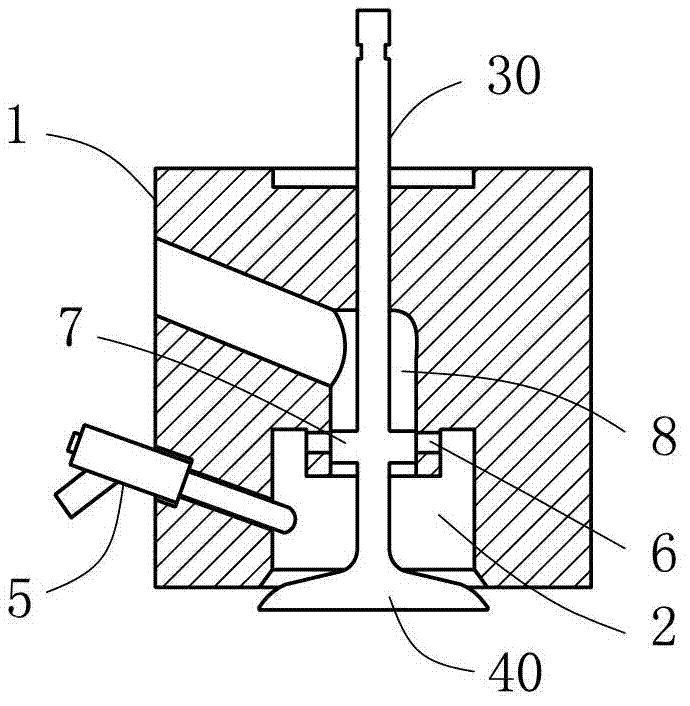

[0023] Such as figure 2 , image 3 and Figure 4 Commonly shown, the main idea is to integrate the liquefied gas fuel liquid direct injection device and the intake valve of the engine into a composite engine valve, including a cylinder head 1 installed on the engine casing, and the cylinder head 1 has an isolation valve with one end open Cavity 2, isolation chamber 2 communicates with the combustion chamber of the engine through the open end, and the valve rod 30 driven by the power device is slidably installed on the cylinder head 1, usually the power device is the engine gas distribution system cam group or electric mode, etc., the technology in the art Personnel can utilize usual technical means to implement, no longer go into details here, the end of valve stem 3 has a valve bacteria valve 40 for sealing the open end of isolation chamber 2; Air intake channel 8, the end of the intake channel 8 is provided with a radial through hole 6 communicating with the isolation cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com