Process pump for petrochemical industry

A technology for petrochemical and process pumps, which is applied to pumps, pump components, and parts of pumping devices for elastic fluids. The effect of prolonging service life, avoiding failure and improving pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

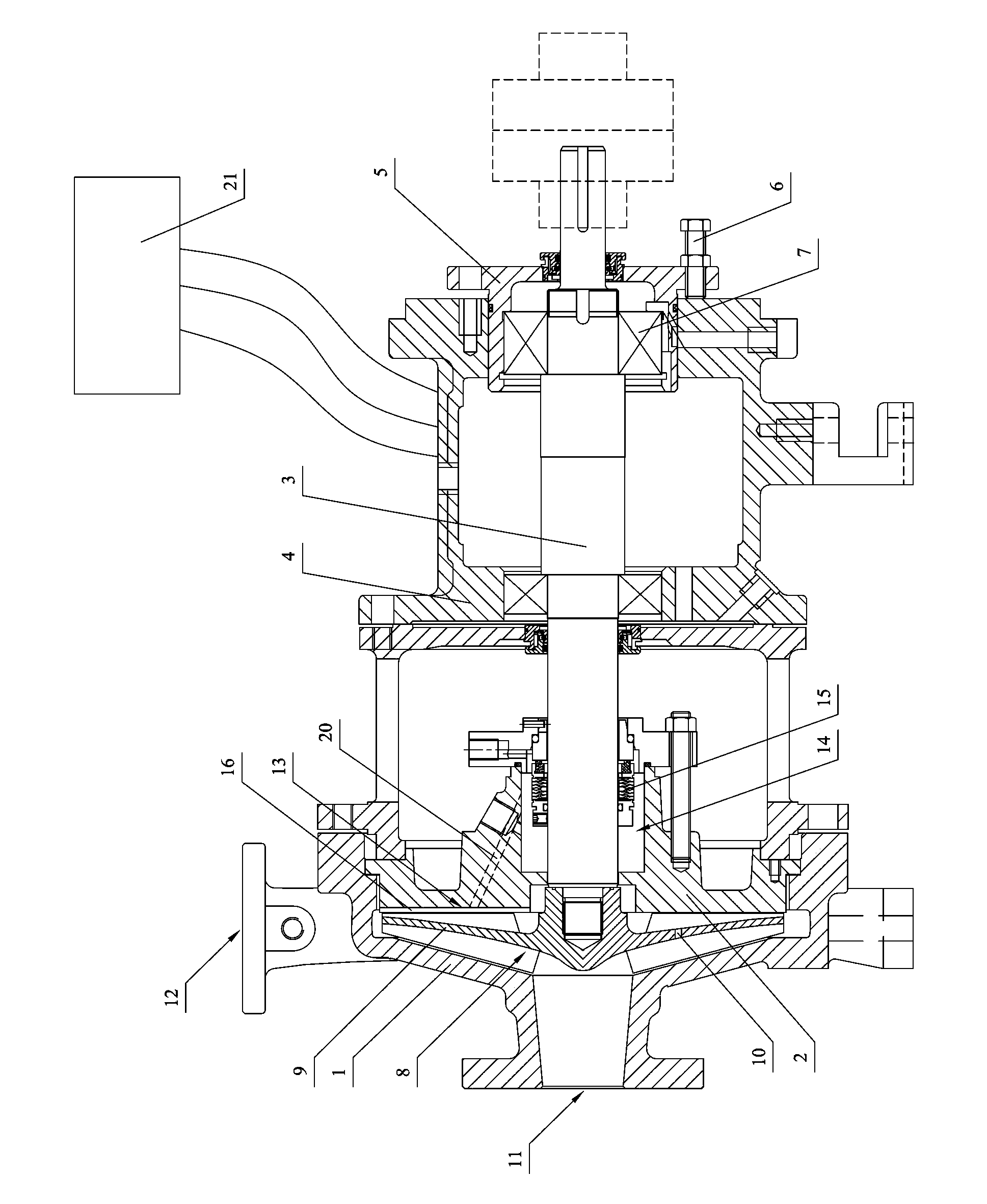

[0024] Embodiment one: see attached figure 1 shown.

[0025] A petrochemical process pump, comprising a pump casing 1, a pump cover 2 connected to the pump casing 1, a pump shaft 3 arranged in the pump casing 1, a bearing housing 4 connected to the pump cover 2, and a pump shaft 3 arranged in the bearing casing 4 The bearing housing 5 that slides in the axial direction of the pump shaft 3. An adjusting screw 6 is arranged between the bearing housing 4 and the bearing seat 5 , a bearing 7 is arranged in the bearing seat 5 , and the pump shaft 3 is arranged in the bearing 7 and its axial direction extends toward the pump cover 2 . The bearing seat 5 can drive the pump shaft 3 and the impeller 9 to move along the axial direction of the pump shaft 3 , thereby effectively controlling the gap between the impeller 9 and the pump casing 1 . In order to monitor and control the operating conditions of the pump in a timely and effective manner, one or more of a liquid level indicator, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com