flame gunning process

A process and flame technology, which is applied in the field of overall spraying and repairing of steelmaking furnace lining in iron and steel companies, can solve problems such as high power of converter rotating motor, high cost per ton of steel, and large overall weight of steelmaking furnace, etc. Achieve the effects of improving steelmaking efficiency, improving corrosion resistance and erosion resistance, and achieving great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

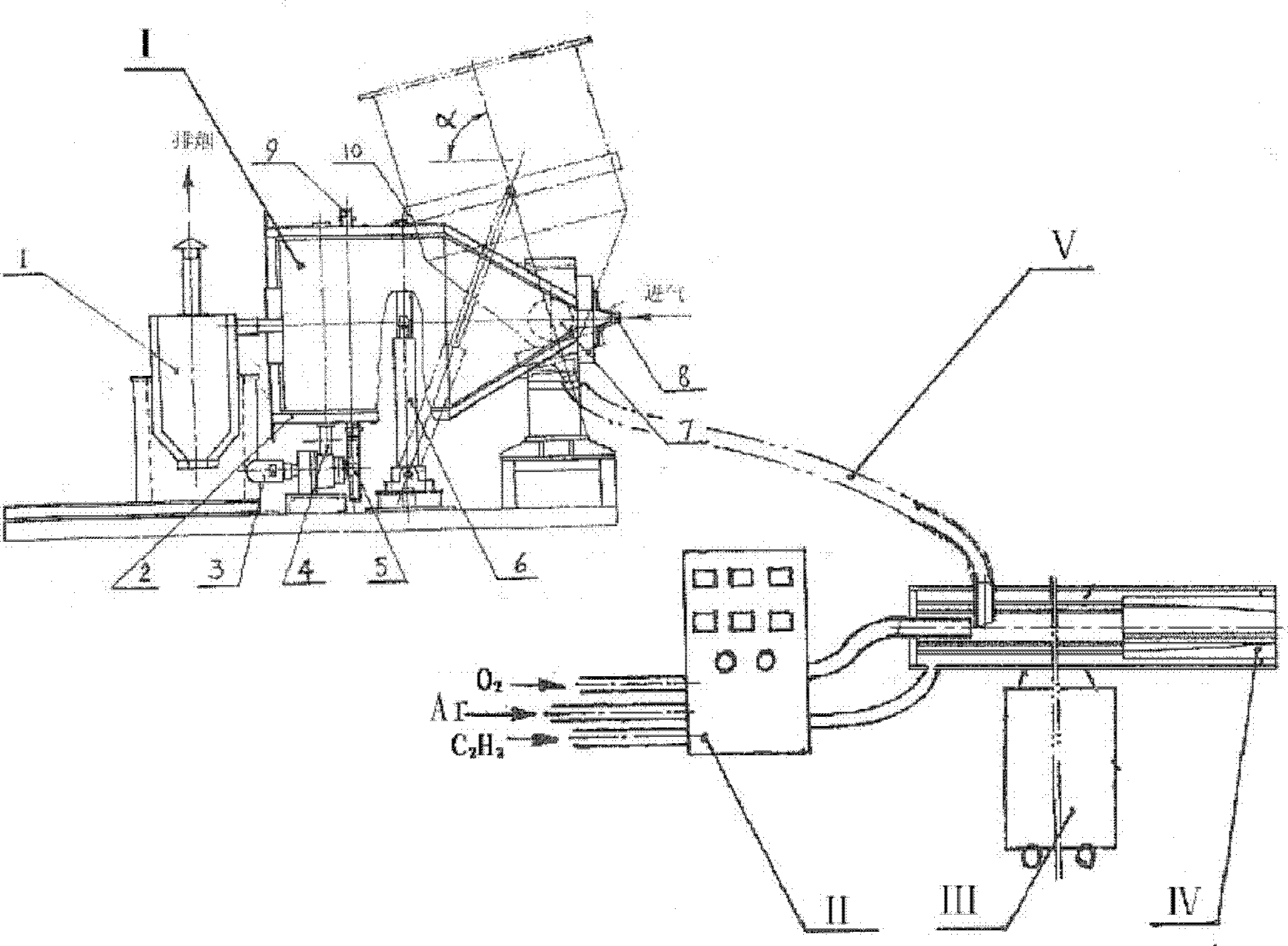

[0015] Flame gunning process, the method of integrally spraying the inner lining of steelmaking furnace is to follow the steps below:

[0016] (1) Preheating: Pour the refractory powder into the preheating material tank and heat it to 700°C-1500°C. During the heating process, the speed of the preheating material tank is 0-20 rpm;

[0017] (2) Overall spraying: connect the discharge port of the preheating material tank with the tail of the spray gun, and 2 , argon, C 2 h 2 The gas source is connected to the corresponding port at the end of the spray gun through a pipeline. According to the spraying operation rules - turn on O in turn 2 、C 2 h 2 After closing the valve, open the feeding valve again. use C 2 h 2 After leaving the focusing nozzle, the high-temperature 2500°C flame belt is about 1.5 meters long. After the refractory powder is fired into a molten state, the inner lining of the new steelmaking furnace is sprayed as a whole. After the spraying is completed, c...

Embodiment 2

[0019] The method of repairing the lining of the steelmaking furnace is to follow the steps below:

[0020] (1) Preheating: Pour the refractory powder into the preheating material tank and heat it to 700°C-1500°C. During the heating process, the speed of the preheating material tank is 0-20 rpm;

[0021] (2) pre-treatment of the lining of the steelmaking furnace: the discharge port of the preheating feed tank is connected with the tail of the spray gun, and the O 2 , argon, C 2 h 2 The gas source is connected to the corresponding port at the end of the spray gun through a pipeline. According to the repair operation procedure - turn on O in turn 2 、C 2 h 2 After the valve, use the high temperature of 2500°C at the focal point after acetylene leaves the focusing nozzle to first melt off a layer of slag on the surface of the steelmaking furnace lining that is eroded by molten steel, and then burn it out on the exposed refractory lining at the eroded portion Cross groove;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com