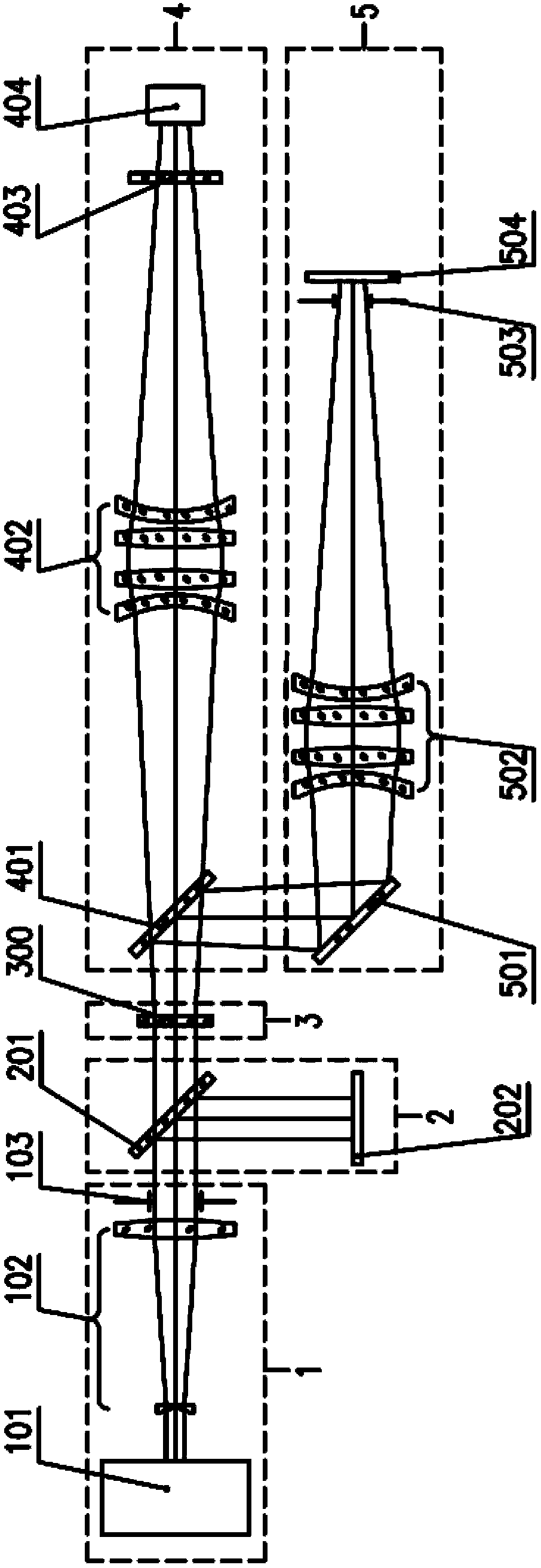

Measuring device and method for optical performance of diffractive optical element

A diffractive optical element and optical performance technology, applied in the field of microlithography, can solve the problem of inaccurate diffraction efficiency, inability to simultaneously measure the energy utilization rate of diffractive optical elements, zero-order diffraction efficiency, high-order diffraction efficiency, and inability to diffract the optical performance of optical elements. Evaluation and other issues to achieve accurate and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

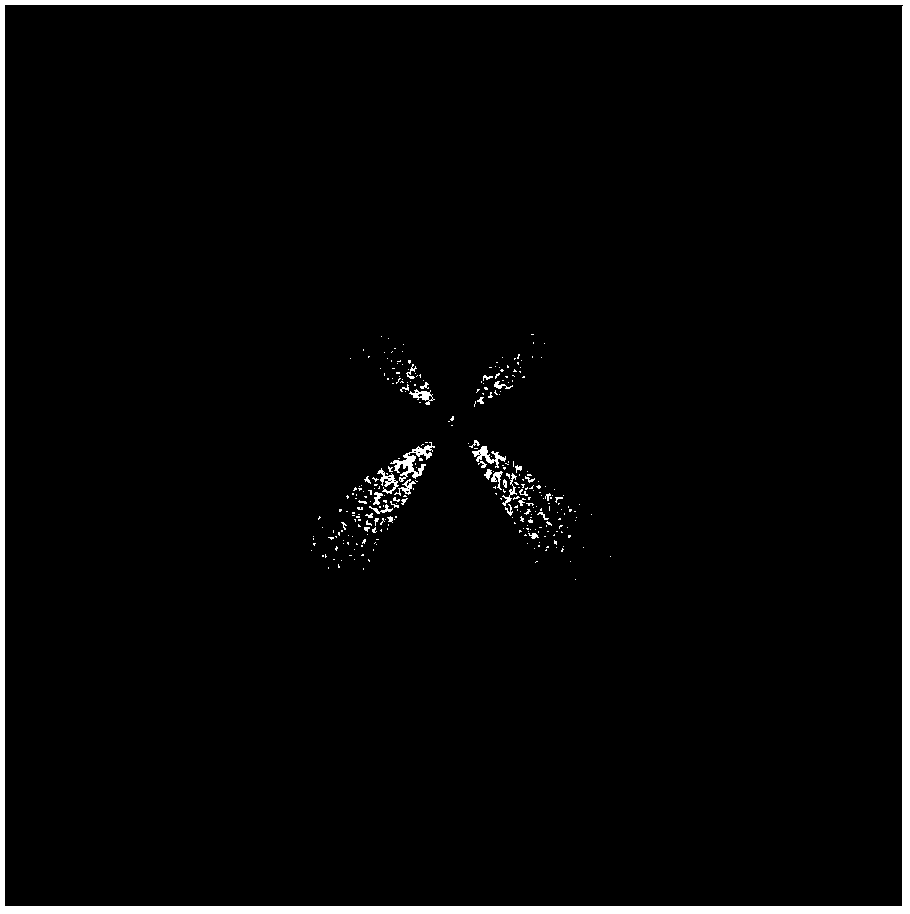

[0076] see figure 2 ,in figure 2 for the use figure 1 The diffraction pattern of a diffractive optical element that produces a quadrupole illumination mode measured by the shown diffractive optical element measuring device has a zero-order bright spot in the center and a high-order diffraction pattern at the edge. Measurements are performed in a dark room.

[0077] The wavelength of the light output by the excimer laser 101 is 193nm, and the size of the outgoing beam is 3mm×3mm; the beam expansion magnification of the beam expander 102 is 10×, and the beam size of the incident beam after the beam expander 102 is expanded is 30mm×30mm; The aperture of the diaphragm 103 is 24 mm×24 mm, and the size of the light beam incident on the diffractive optical element 300 to be tested is 24 mm×24 mm.

[0078] The focal length f and the clear aperture D of the first Fourier transform lens 402 are respectively determined by formula (1) and formula (2). The size of the sensitive surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com