Prism sheet for backlight unit and liquid crystal display module

A backlight unit and prism sheet technology, applied in prisms, optical components, optics, etc., can solve problems such as difficult to display images, achieve the effects of suppressing phase difference changes, improving optical uniformity, and promoting large-screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Using a cyclic olefin copolymer ("TOPAS8007" manufactured by Polyplastics Co., Ltd.), after pre-drying, it was melt-extruded on a cooling roll using a single-screw extruder (L / D=35), and a film with a thickness of 100μm optical film.

Embodiment 2

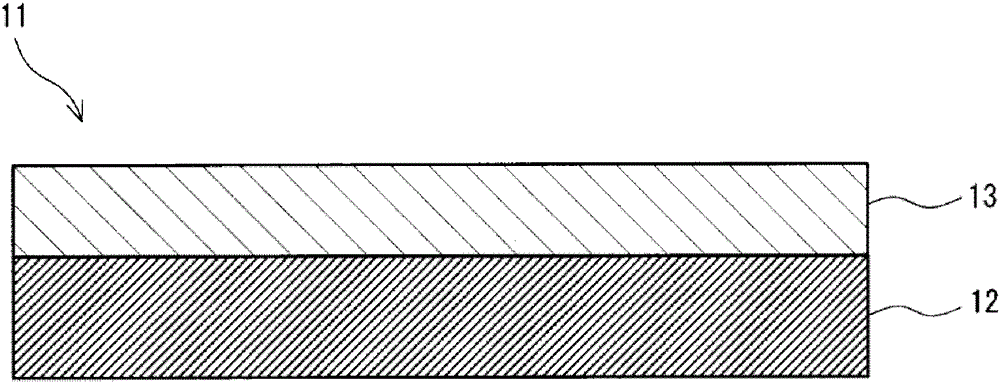

[0105] The optical film produced in Example 1 was subjected to ITO treatment by sputtering to produce an optical sheet (transparent conductive sheet) having a transparent conductive layer on one surface of the optical film.

Embodiment 3

[0107] On the optical film made in Example 1, a hard coat agent ("Ultraviolet UV-7605B" manufactured by Nippon Synthetic Chemical Industry Co., Ltd.) was applied to make the film thickness of the hard coat layer 5 μm, and it was cured to produce An optical sheet (hard coat film) having a hard coat layer on one side of the optical film was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com