Method for operating an ignition device for an internal combustion engine, and ignition device for an internal combustion engine for carrying out the method

An ignition device and internal combustion engine technology, which is applied in the direction of engine ignition, other devices, induction energy storage devices, etc., can solve the problems of serial engines that cannot be ignited in key operating states, and wear of ignition plugs, so as to improve ignition safety and ensure reliability The effect of forming and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

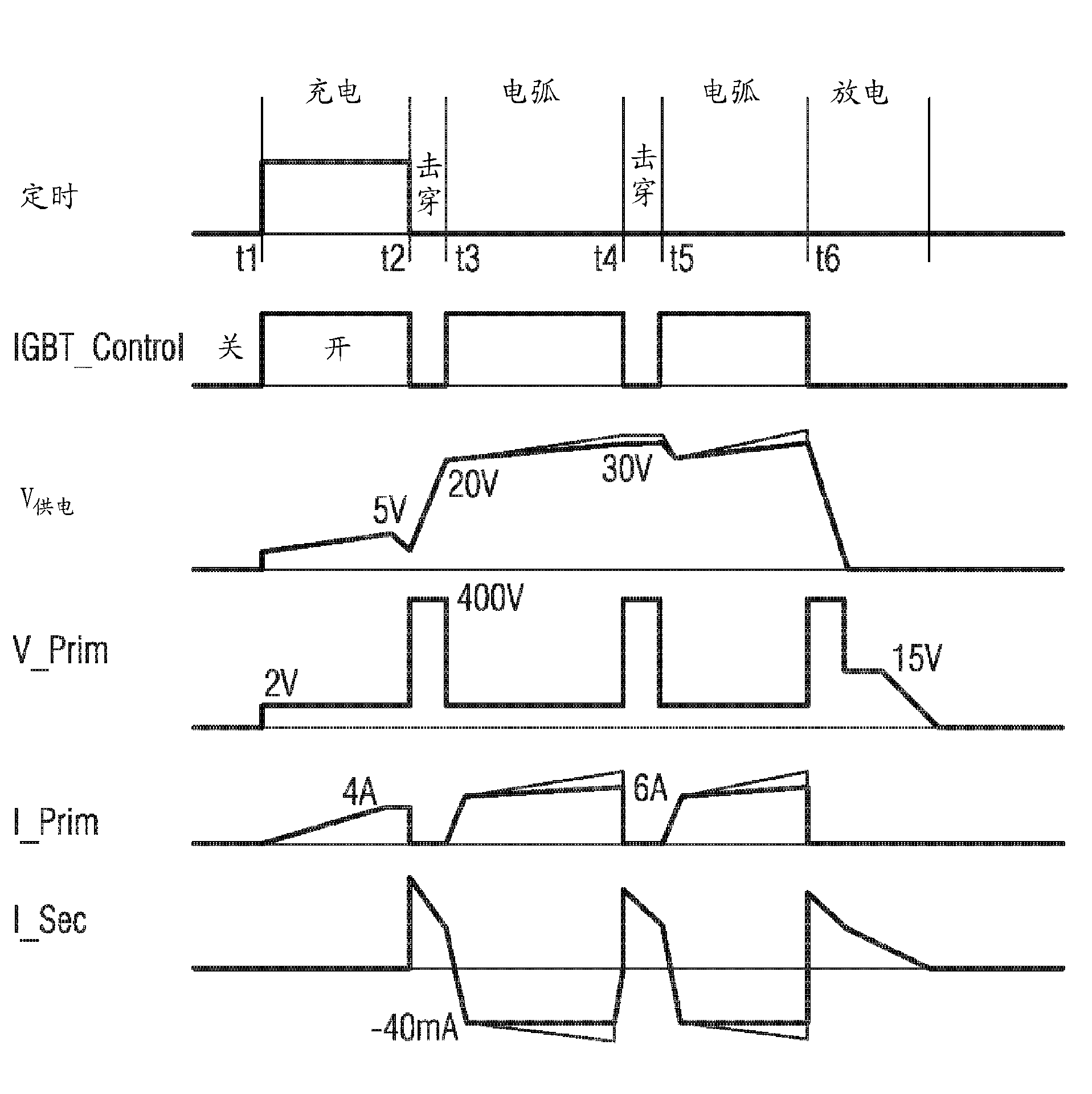

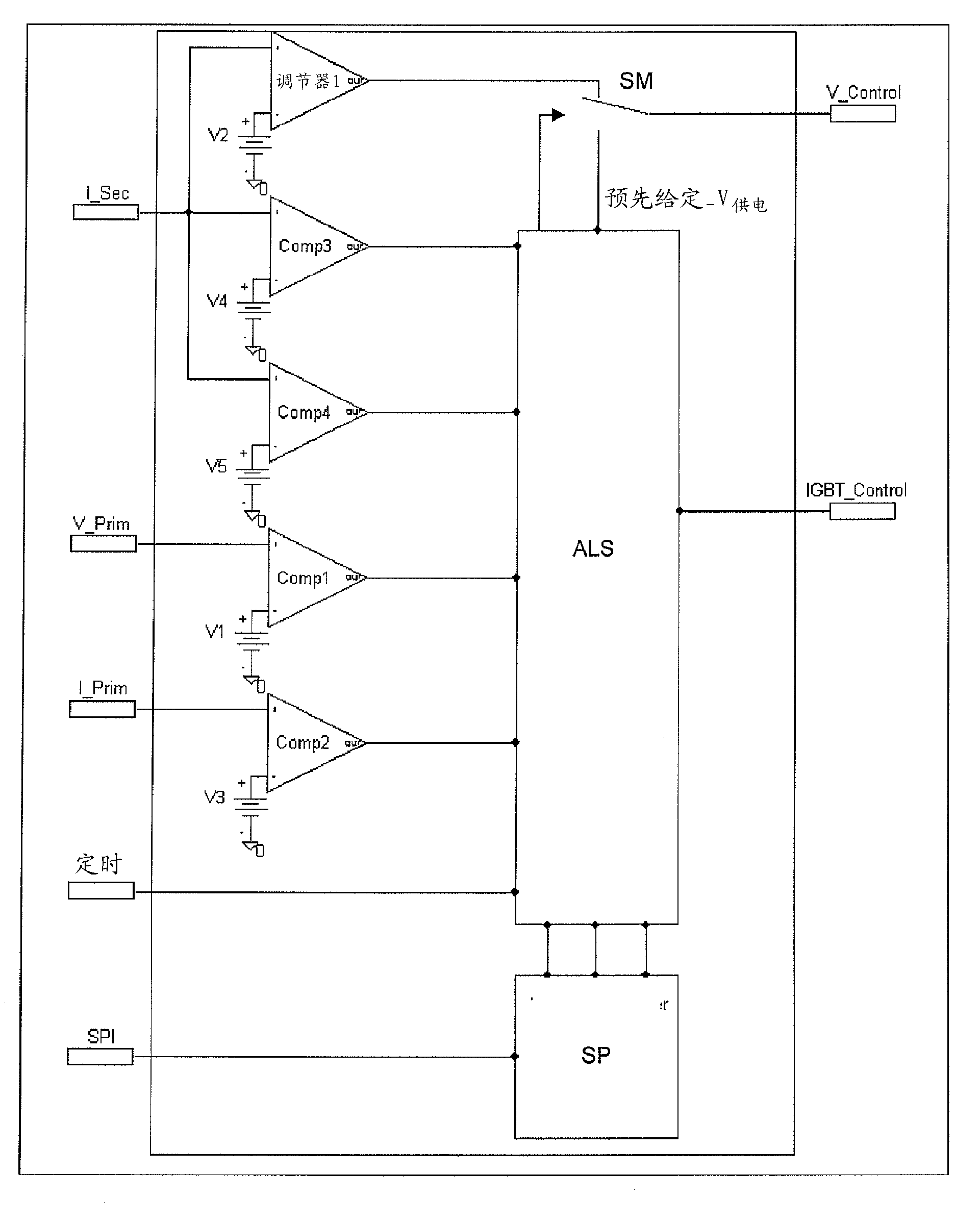

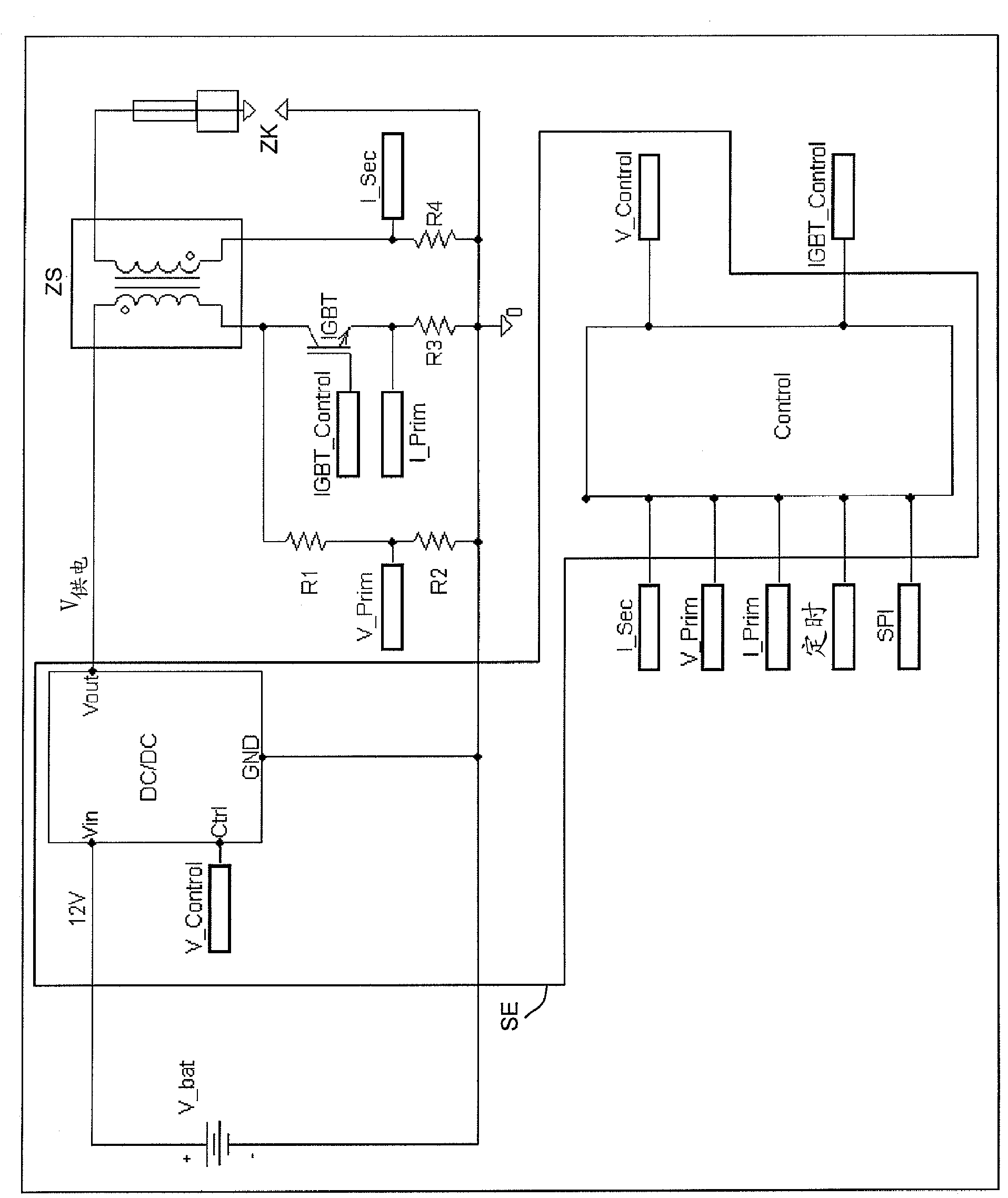

[0037] according to figure 1 The ignition device according to the invention comprises a controllable supply voltage source DC / DC configured as a voltage converter for supplying one or more ignition coils ZS with a variable supply voltage V 供电 . The supply voltage is supplied from the vehicle supply voltage V_bat, which is currently approximately 12V. This supply voltage supplies one or more ignition coils ZS, advantageously no blocking diodes being required anymore. A conventional glow plug ZK can be used, which is connected to the secondary winding of the ignition coil ZS. The primary winding of the ignition coil ZS is connected in series with a switching element, usually designed as an IGBT, for switching the ignition coil ZS. Means are provided for detecting the primary voltage as well as the primary and secondary currents.

[0038] The control unit SE generates a variable supply voltage V by means of a voltage converter DC / DC depending on the detected operating paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com