Double-arm full-automatic material loading and unloading device for tapered roller bearing inner race crowned grinding machine

A tapered roller bearing, fully automatic technology, applied to grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problems of low efficiency, achieve simple structure, reduce loading and unloading time, The effect of simplification of the drive mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

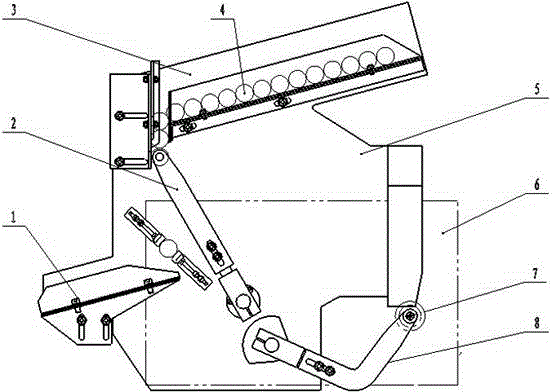

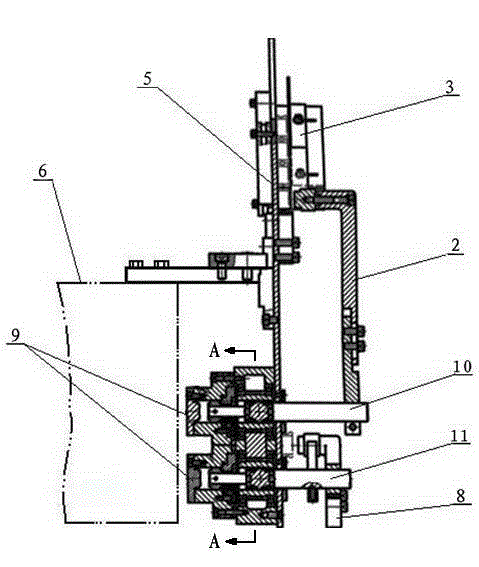

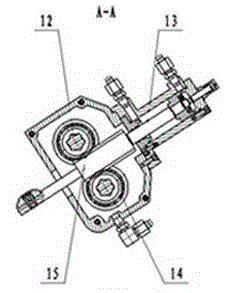

[0011] figure 1 , figure 2 and image 3 It is a double-arm automatic loading and unloading device for a precision CNC tapered roller bearing inner ring crown grinder model 3MK2110T. 1, the installation substrate 5 is installed on the grinding machine head box 6 through the fixing bracket on the reverse side, the feeding channel 3 is arranged above the front of the installation substrate 5, and the unloading channel 1 is arranged on the lower left side of the front of the installation substrate 5, its characteristics Yes: it also contains a feeding manipulator 2, a feeding manipulator 8, two synchronous hydraulic cylinders 9, a swing hydraulic cylinder 13 and a swing shaft assembly 12, the synchronous hydraulic cylinder 9, swing hydraulic cylinder 13 and The swing shaft assembly 12 is combined into one, and is arranged at an appropriate position below the reverse sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com