Curved surface paper flattening device for chain wheel motion of printing machine

A technology of flattening device and printing machine, which is applied to the general parts of printing machinery, printing machines, printing, etc. It can solve the problems of affecting printing quality, false detection, and flattening of difficult-to-move paper, and achieves good detection quality, simple operation, The effect of convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

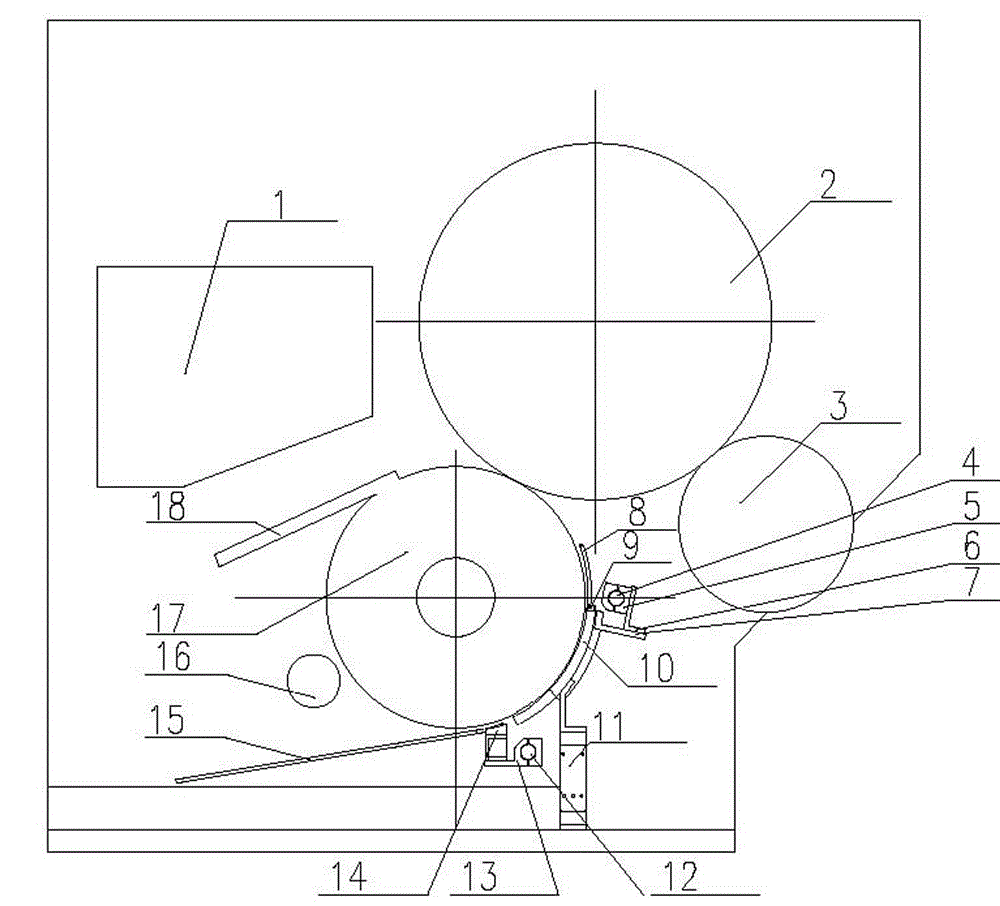

[0019] like Figure 1 to Figure 5 As shown, a curved paper flattening device for sprocket movement of a printing machine is composed of a vacuum pump 20, a quick-plug connector 21, an air pipe 22, a pressure equalizing box 24 and a regulating valve 23. The paper flattening device includes a suction Spreading plate assembly, air circuit device and blowing flattening device. The present invention is used in the traditional printing machine take-up cylinder 17, where the printing machine body is also equipped with a printing machine liner 1, a printing machine cylinder 2, a printing small cylinder 3, a printing machine upper pull shaft 4, and an upper holding shaft 5 , pull down shaft 12, hold down shaft 13, pull shaft 16 and delivery chain 18 after.

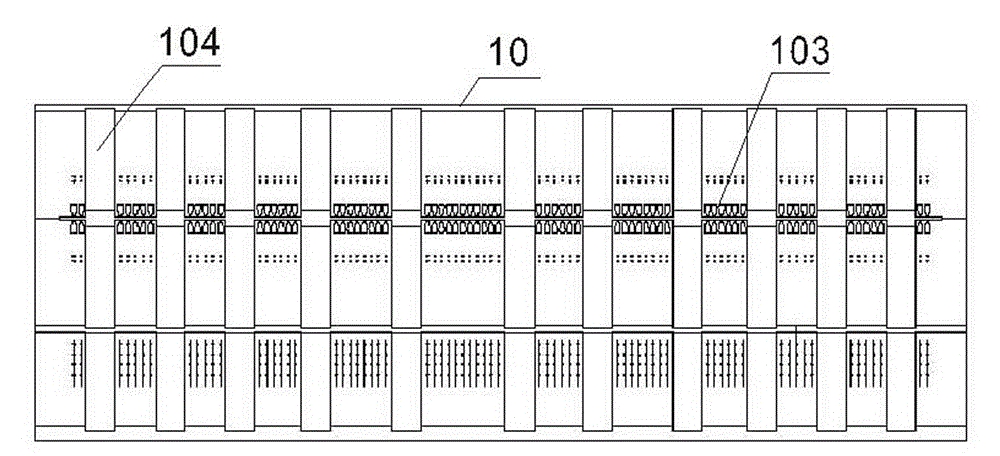

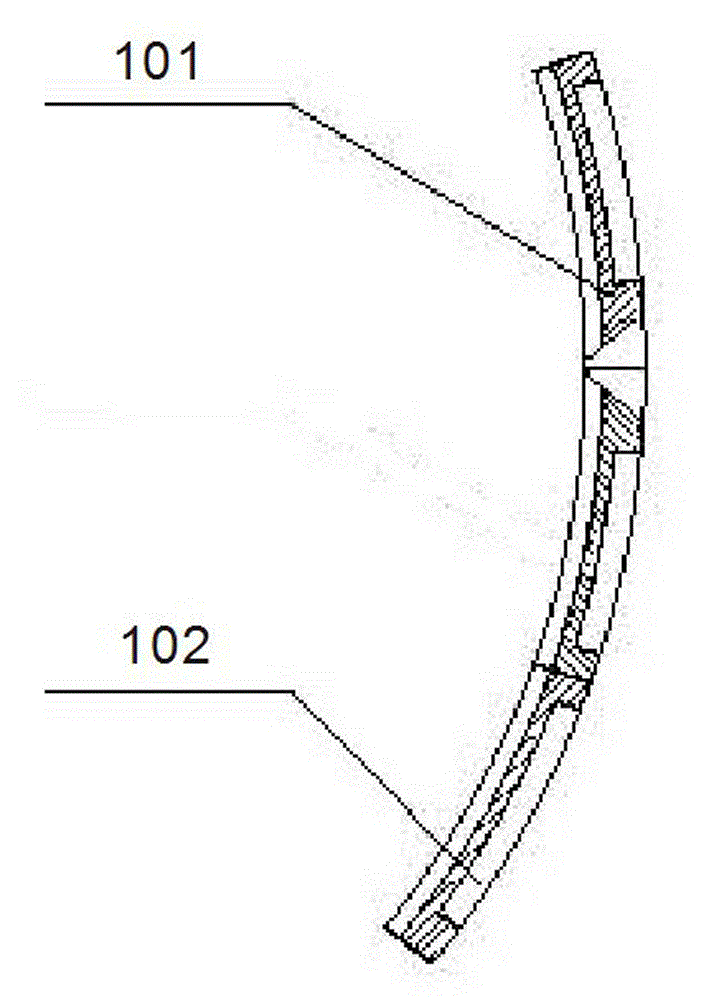

[0020] The air suction flat panel assembly 10 of the present invention is composed of an upper curved panel 101 and a lower curved panel 102, and the air suction flat panel assembly is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com