Automotive wiring harness assembly production line and workpiece conveying device

A technology of automotive wiring harness and conveying device, which is applied in the direction of transportation, packaging, and slideway, etc., can solve the problems of the rhythm of the production of the wiring harness, terminal deformation, extrusion, etc., and achieve the effect of extending the service life, transporting lightly, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

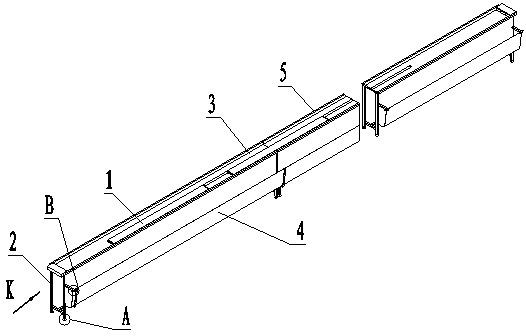

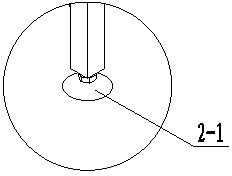

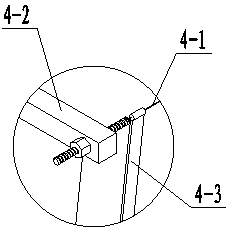

[0022] Referring to Fig. 1, the present invention comprises slide plate type packing table 1, conveying slide rail assembly 3, protective cloth pocket 4, anti-line leather scratch light pipe 5 and slide rail support 2, and described slide plate type packing table 1 quantity is as big as automobile The number of SUB unit groups contained in the wiring harness assembly is matched (generally, the automotive wiring harness assembly is divided into five SUB unit groups, plus a spare set, and the number of corresponding slide-type sub-assembly tables 1 is six), and the slide-type sub-assembly table 1 Assembled with the conveying slideway assembly 3, both sides of the conveying slideway assembly 3 are equipped with anti-line leather scratch light pipes 5, the conveying slideway assembly 3 is fixed on the slideway bracket 2, and the protective cloth Pocket 4 is installed on the side of slide rail support 2, and described slide rail support 2 is installed on the level ground.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com