Acid-resistant anti-aging flame-retardant color masterbatch and preparation method thereof

A color masterbatch, anti-aging technology, applied in the polymer field, can solve the problems of ineffectiveness and loss of function, and achieve the effect of not easy to fade, good surface gloss and rich colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] materials Mass / kg Polyethylene (LLDPE MI=5) 39 R-titanium dioxide 50 EBS-Silica 1 (the mass ratio of EBS and silica is 1:0.3) Triazine Derivatives 10

[0038] The preparation steps are as follows:

[0039] (1) According to the prescription, add various ingredients into the mixer and mix at high speed for 5 minutes;

[0040] (2) Heat the screw extruder at a temperature of 180°C as required, and after 20 minutes of constant temperature, add the ingredients mixed in step (1), start extruding, and granulate and form by cooling with water.

[0041] (3) The finished white masterbatch in (2) is used in the molding and processing of natural polyethylene products at a mass ratio of 1:10 to obtain white acid-resistant, anti-aging, flame-retardant polyethylene products.

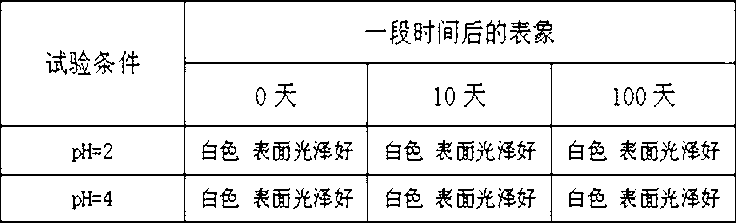

[0042] The compatibility and coloring effect of the white masterbatch with the natural polyethylene resin in the step (3) and the acid resistance, anti-aging and flame re...

Embodiment 2

[0050] materials Mass / kg Polyethylene (LLDPE MI=5) 48 Compound iron yellow 35 EBS-Silica 2 (the mass ratio of EBS and silica is 2:0.5) Stabilizer NOR 15

[0051] The preparation steps are as follows:

[0052] (1) According to the prescription, add various ingredients into the mixer and mix at high speed for 5 minutes;

[0053] (2) Heat the screw extruder at a temperature of 150°C as required, and after 30 minutes of constant temperature, add the ingredients mixed in step (1), start extruding, and granulate and form by cooling with water.

[0054](3) The finished yellow masterbatch in (2) is used in the molding and processing of natural polyethylene products at a mass ratio of 1:10 to obtain yellow acid-resistant, anti-aging, flame-retardant polyethylene products.

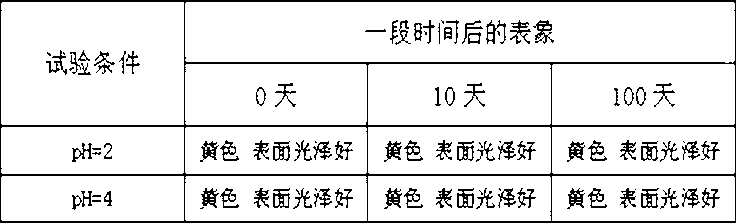

[0055] The compatibility and coloring effect of the yellow masterbatch with the natural color polyethylene resin in the step (3) and the acid resistance, aging resistance an...

Embodiment 3

[0063] materials Mass / kg Polyethylene (LLDPE MI=5) 50 macromolecular red 30 EBS-Silica 5 (the mass ratio of EBS and silica is 4:0.8) Stabilizer NOR 15

[0064] The preparation steps are as follows:

[0065] (1) According to the prescription, add various ingredients into the mixer and mix at high speed for 5 minutes;

[0066] (2) Heating the screw extruder at a temperature of 140 °C as required, and after 25 minutes of constant temperature, add the ingredients mixed in step (1), start extruding, and granulate and shape by water cooling.

[0067] (3) The finished red masterbatch in (2) is used in the molding and processing of natural polyethylene products at a mass ratio of 1:10 to obtain red acid-resistant, anti-aging, flame-retardant polyethylene products.

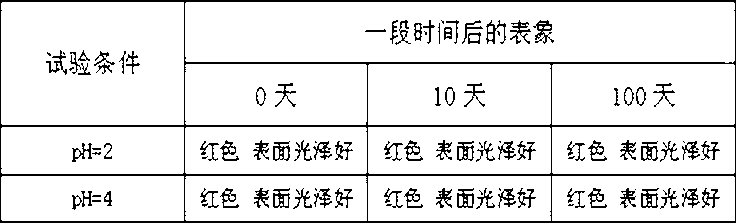

[0068] The compatibility and coloring effect of the red masterbatch with the natural polyethylene resin in the step (3) and the acid resistance, anti-aging and flame retardant prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com