Method and device for recycling oil products of scrapped car

A technology for scrapping automobiles and oil products, which is applied in the multi-stage series refining process treatment, lubricating composition, etc., can solve the problems of decreased competitiveness, difficult treatment, secondary pollution, etc., to reduce the amount of acid residue and save Operation process, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

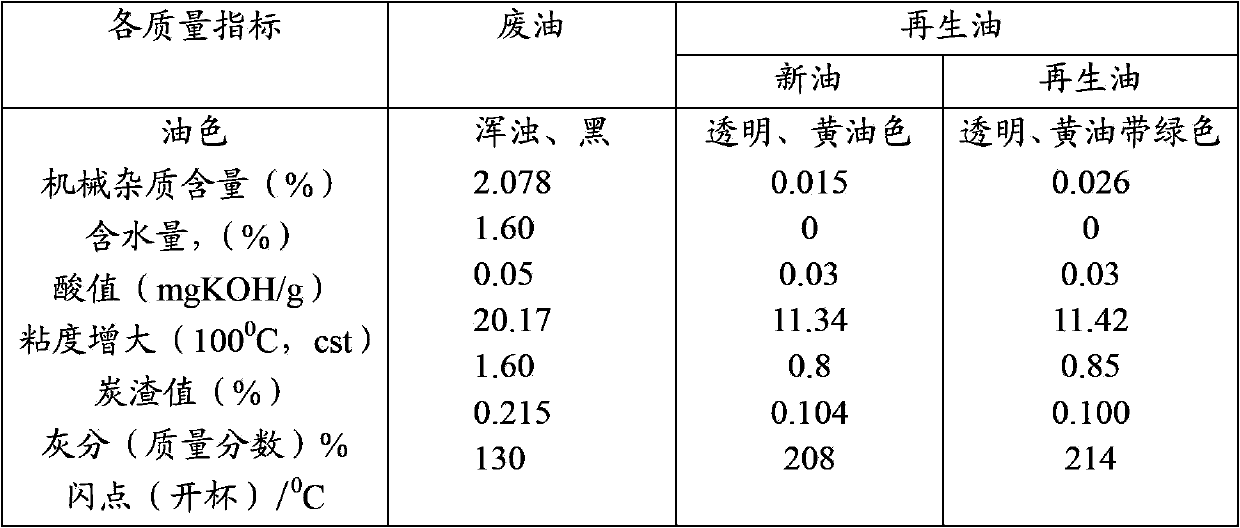

Examples

Embodiment 1

[0049] A method for recycling waste automobile oil, comprising the following steps:

[0050] (1) Collect waste engine oil in scrapped cars, including various oils and waste liquids, such as residual fuel in the fuel tank, engine oil in the engine case, transmission oil, coolant, brake fluid and lubricating oil, etc. These waste liquids Separately recover through different pipelines to be processed;

[0051] (2) Preparation of activated clay: Mix distilled water and bentonite (150 mesh) at a ratio of 1L:1.5kg, then add hydrochloric acid accounting for 15% of the mass of bentonite, stir evenly, and then react at 100°C and 2MPa for 2.5h; then add Distilled water (the volume added to the reactant accounts for half of the volume of the reaction vessel) and silver nitrate, react for 15 minutes to form a white precipitate; let it stand for 50 minutes, pour off the supernatant, drain the precipitate, dry, and pulverize to obtain activated clay;

[0052] The amount of silver nitrate u...

Embodiment 2

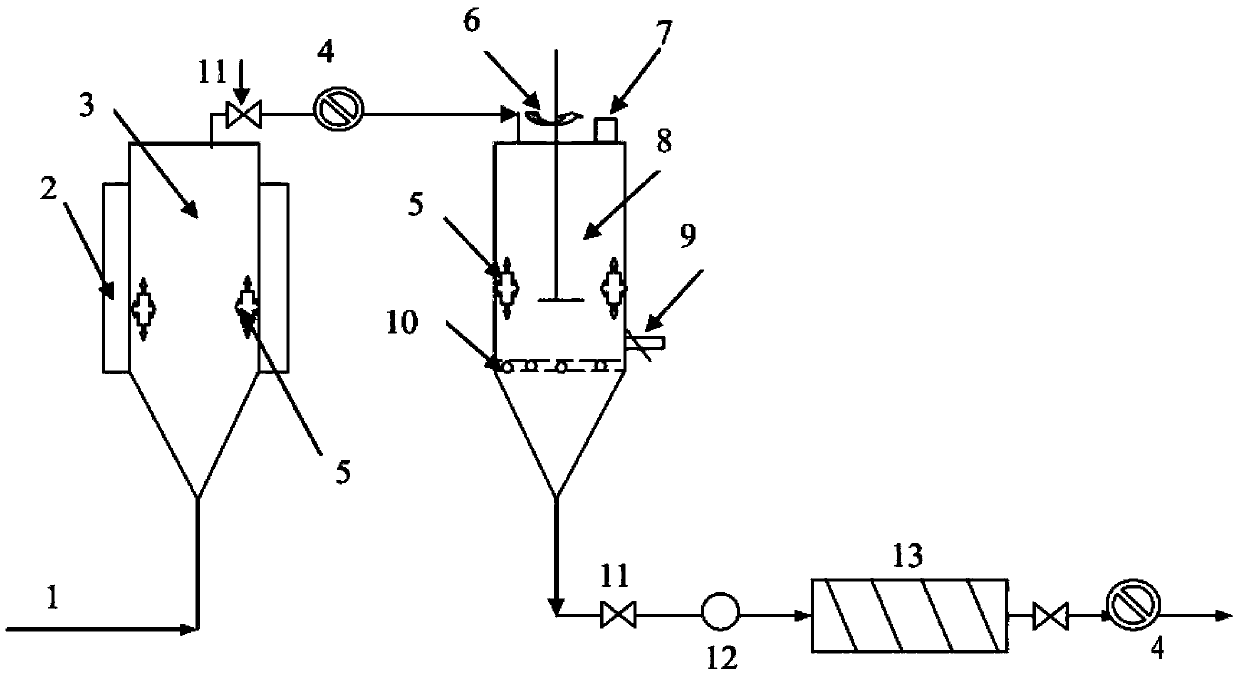

[0062] A kind of device that is used to realize the method described in embodiment 1 will recycle the waste automobile oil product, its structure is as follows figure 1 As shown, it mainly includes pickling settling tank 3, distillation still 8 and plate and frame filter press 13, and the three are connected successively;

[0063] The adopted pickling settling tank 3 is a cylindrical tank with a conical bottom. The outer circumference of the cylindrical tank is the insulation layer 2, which is a solid structure made of PVC (polyvinyl chloride) or RPP (reinforced polypropylene), the insulation layer 2 can avoid the temperature difference between the external environment and the oil The circulation of the settling oil can achieve a better settling effect; the conical bottom of the pickling settling tank 3 is provided with a drain valve, which is not only the inlet of waste engine oil, but also used to discharge mechanical impurities after pickling and settling; The middle and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com