Preparation process of reinforced intragranular aluminum matrix composites with nano ceramic particles added externally

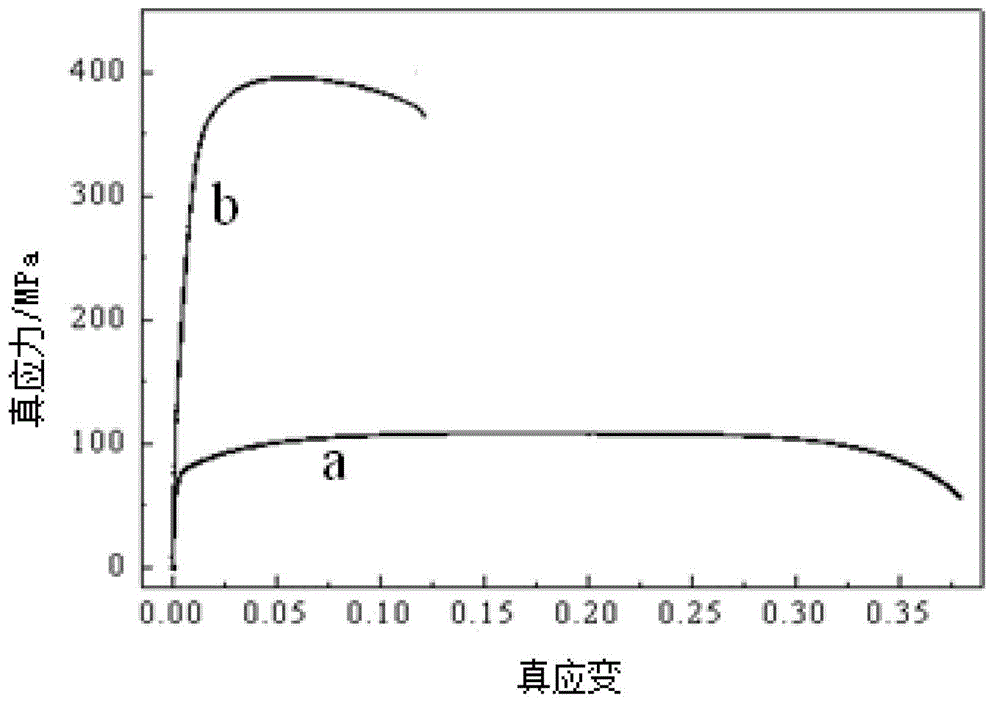

A technology of nano-ceramic particles and aluminum-based composite materials, which is applied in the field of preparation of ceramic-particle-reinforced aluminum-based composite materials, can solve the problems of low strength, low plasticity, and difficult to control the particle size of nano-particle-reinforced aluminum-based composite materials, and achieves improved strength. , good plasticity, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

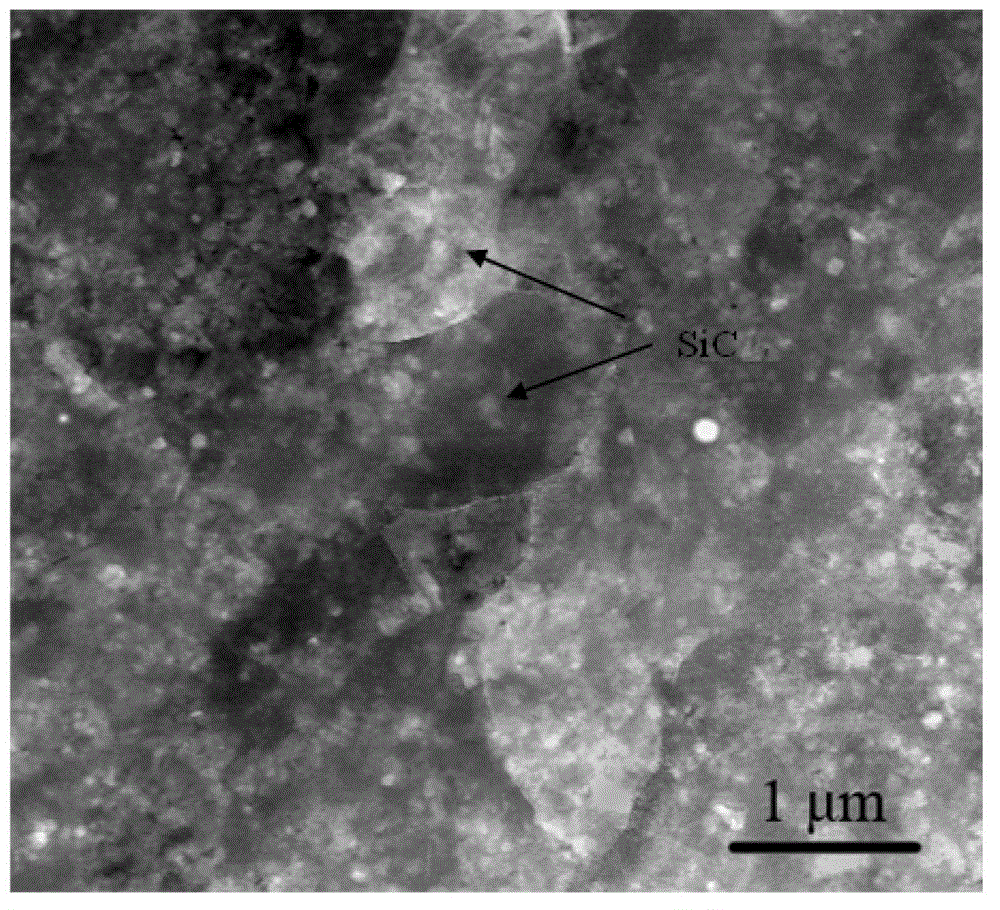

[0021] Specific embodiment 1: In this embodiment, an intragranular aluminum-based composite material reinforced with nano-ceramic particles is composed of 1-10 parts by volume of nano-ceramic particles and 90-99 parts of alloy; wherein, the alloy is aluminum powder or Aluminum alloy powder.

[0022] The method of this embodiment can overcome the limitation of the types of in-situ synthesized particles and the disadvantages that the corresponding size is difficult to control. The size range of the reinforcement can be strictly controlled by adding nano-ceramic particles, and the metal-matrix composite reinforced by adding nano-ceramic particles can be accurately prepared. Material.

specific Embodiment approach 2

[0023] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the ceramic particles are SiC ceramics, SiO 2 , MgO, TiB 2 、A1 2 o 3 、Si 3 N 4 or TiC. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the particle size of the ceramic particles is 20-100 nm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com