12-gear full-helical-tooth double-intermediate-shaft all-synchronizer gearbox

A technology of double intermediate shafts and synchronizers, used in clutches, mechanical drive clutches, gear lubrication/cooling, etc., can solve the problems of low assembly bearing capacity, large shifting force, damaged gear teeth, etc., and improve the gear bearing capacity. , the effect of reducing shock and noise, and high fuel economy

Inactive Publication Date: 2012-10-24

SINO TRUK JINAN POWER

View PDF7 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the common heavy-duty truck gearbox structure with double countershaft structure, it is necessary to align the teeth of the two countershaft gears to ensure the consistency of the two countershaft assemblies. , the noise is large; the main box generally adopts the meshing sleeve to shift gears. When shifting from one gear to another, since the meshing line speeds of the pair of gears or the meshing sleeves to be meshed during the gear shift are not equal, The impact occurs during the operation, causing noise, and even damage to the gear teeth, resulting in early wear and tear, and the driver needs a large shifting force during operation, which is easy to cause fatigue

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

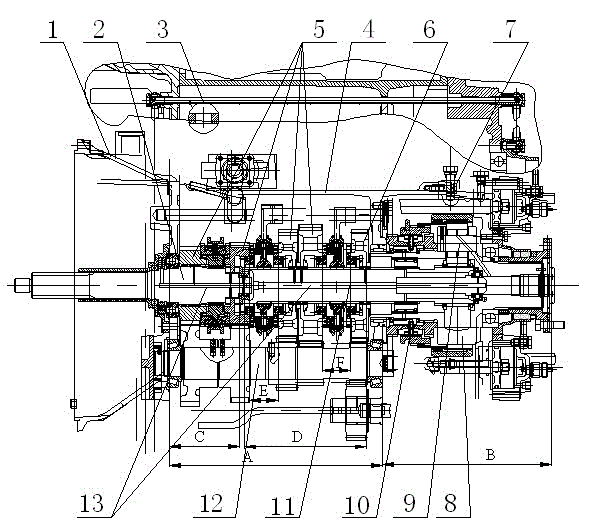

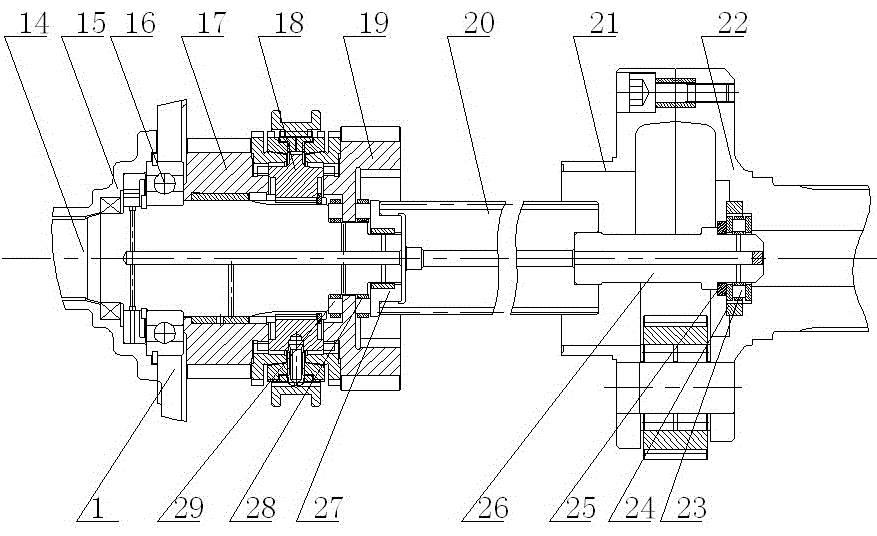

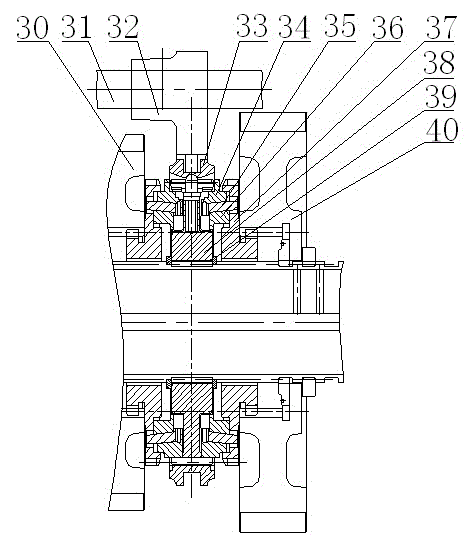

The invention relates to a 12-gear full-helical-tooth double-intermediate-shaft all-synchronizer gearbox which adopts a design of combination of a three-section closed structure shell and main and auxiliary gearboxes. The main gearbox is of a small-center-distance double-intermediate-shaft structure and gears adopt large-tooth wide helical teeth, so that the bearing capacities and the meshing stabilities of the gears are improved, the meshing noise is reduced and the bearing cavity of the main gearbox is improved. Due to the adoption of an input drop-and-insert structure, the gear speed ratio order difference is small and the fuel economy is high. Double-cone inertial type of synchronizers are respectively and additionally arranged at an inverted first gear and second and third gears, so that the friction moments of the synchronizers are increased, the gear shifting force is reduced and the impact and noise which are generated in the gear shifting process are reduced. Due to the adoption of a helical tooth planet gear system structure, the bearing capacities of the gears are improved; and a planet gear system is designed with the axial limit, so that the helical tooth axial force is offset inside. Due to the adoption of an installing form of an auxiliary gearbox synchronizer, the torque states of a planet carrier at the high and low gears in a certain range are optimized and the torsional strength of a planet carrier assembly is greatly improved. By the double-support design of both the front and rear ends of the planet carrier, the influence of finished automobile factors on the normal work of the inside of the gearbox is reduced.

Description

technical field [0001] The invention relates to a 12-speed full-helical double countershaft full-synchronizer gearbox. Background technique [0002] In the common heavy-duty truck gearbox structure with double countershaft structure, it is necessary to align the teeth of the two countershaft gears to ensure the consistency of the two countershaft assemblies. , the noise is large; the main box generally adopts the meshing sleeve to shift gears. When shifting from one gear to another, since the meshing line speeds of the pair of gears or the meshing sleeves to be meshed during the gear shift are not equal, When the gear is impacted, it will cause noise and even damage the gear teeth, resulting in early wear and tear, and the driver needs a large shifting force during operation, which is easy to cause fatigue. [0003] In view of the above-mentioned problems in the heavy-duty truck gearbox with double countershaft structure, it is necessary to take measures in the gearbox stru...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16H57/023F16H57/021F16H57/038F16H57/08F16H57/04F16D23/02

Inventor 胡凯王辉杨伟玲任宪群

Owner SINO TRUK JINAN POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com