Structural non-linear fatigue damage testing system

A nonlinear fatigue and testing system technology, applied in the field of test equipment manufacturing, can solve problems such as performance and life testing, and achieve the effect of large adjustment range, convenient adjustment and convenient installation of test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

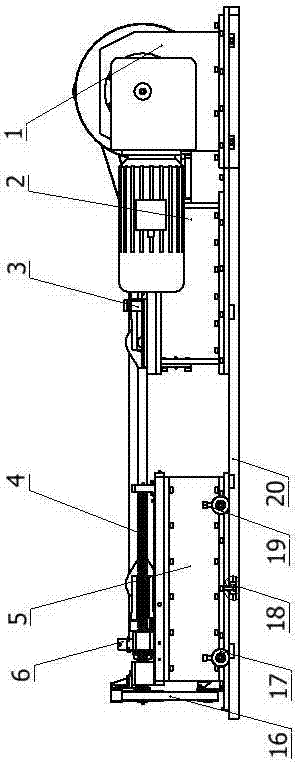

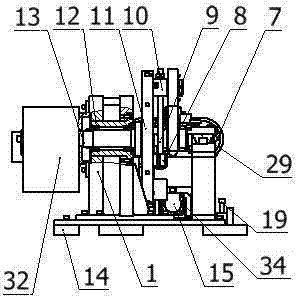

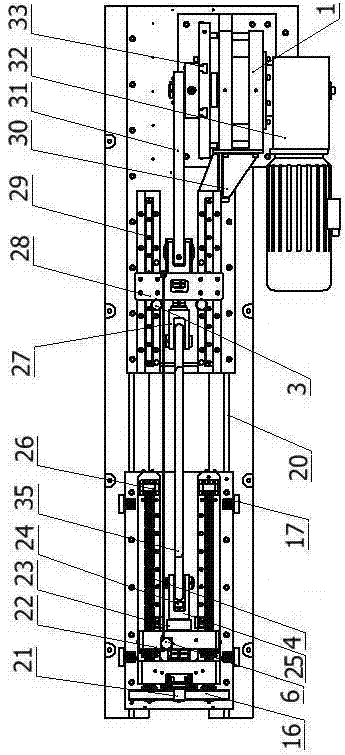

[0010] The dynamic balance wheel support 1 is fixedly connected to the fixed guide rail 20 of the whole machine foundation, the dynamic part support 2 is fixedly connected to the dynamic balance wheel support 1 through the reinforcement beam 30, and is fixedly connected to the fixed guide rail 14 of the frequency conversion motor foundation and the fixed guide rail 20 of the whole machine foundation, Constitute an integral closed frame, the dynamic part positioning block 3 is fixedly connected with the dynamic part bracket 2, the T-shaped screw 4 is fixedly connected with the moving beam 22 and the synchronous pulley 7 through the T-shaped screw bearing fixing seat 26, and the position of the eccentric wheel is adjusted The support 8 is fixedly connected with the balance wheel 11, the two ends of the eccentric wheel adjustment lead screw 9 are respectively fixedly connected with the eccentric wheel position adjustment support 8 and the swing rod moving seat 10, the eccentric whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com